Guide

- How to Calculate 3D Printing Price (SLS, SLA, SLM, MJF, FDM, ETC.,)

- Anodizing vs. Painting: An In-depth Analysis

- 9 Types of 3D Printed Metal Copper Techniques

- 3D Printing Materials and How to Choose the Right One?

- What Is Micro Manufacturing Technology

- Wire 3D Printing: Process, Filament, Printer and Features

- Uncover The Mystery Of CNC Machining

- Huazhong University of Science and Technology has made new breakthroughs in ultrafast laser 3D printing of fine and complex semiconductor micro-nano structures

- In 2025, there will be more than 600 metal 3D printing equipment serving China’s aerospace and other fields

- Looking at the development trend of 3D printing from Formnext 2021

- 3D printed prototype silica gel molds, realizing small batch production of industrial products

- Global architectural 3D printing inventory, no need to move bricks to build a house

- The latest application cases of 3D printing in aviation

- 3D printing everything? Japanese media: Printable buildings, parts, organs and even food…

- 3D printing provides emergency production of anti-epidemic products, global anti-epidemic

Case Studies

Top Additive Manufacturing Solutions

With Our Customer

Help them bring innovation to market faster

3d-printing-china.com Service Type

Provide 3D digital solutions such as reverse engineering, industrial inspection, cultural relic protection, etc.

According to your real needs, we will help you design and develop the most suitable 3D printing solution.

Strong technical team can make your model finished product achieve the color matching effect you want.

Using the latest technology and powerful 5-axis machine to produce precision parts for specific needs

CHINA TOP 3D Printing SERVICE SUPPLIER

- Plastic 3D Printing & Metal 3D Printing

- Imported industrial grade printing equipment

- Accuracy can reach 0.02mm

- Variety of different materials and more options

- Comprehensive design software and skilled engineer enables sample to be done within 7-10 days

- Variety of different materials and more options

- Complete set of inspection equipment & quality control makes excellent 3d printing products

- From prototypes to end parts, upload your 3D files, fast and professional quote in 1-24 hours

- Over 200,000 different parts have been printed over the years

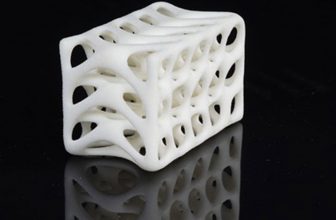

PTJ 3D Printing has nearly 100 industrial-grade 3D printing equipment such as selective laser melting, three-dimensional light curing, selective laser sintering, and multi-jet melting, which can meet all your metal/non-metal 3D printing application needs.

Industry Application Of 3D Printing

PTJ Inc Case studies Of 3D Printing

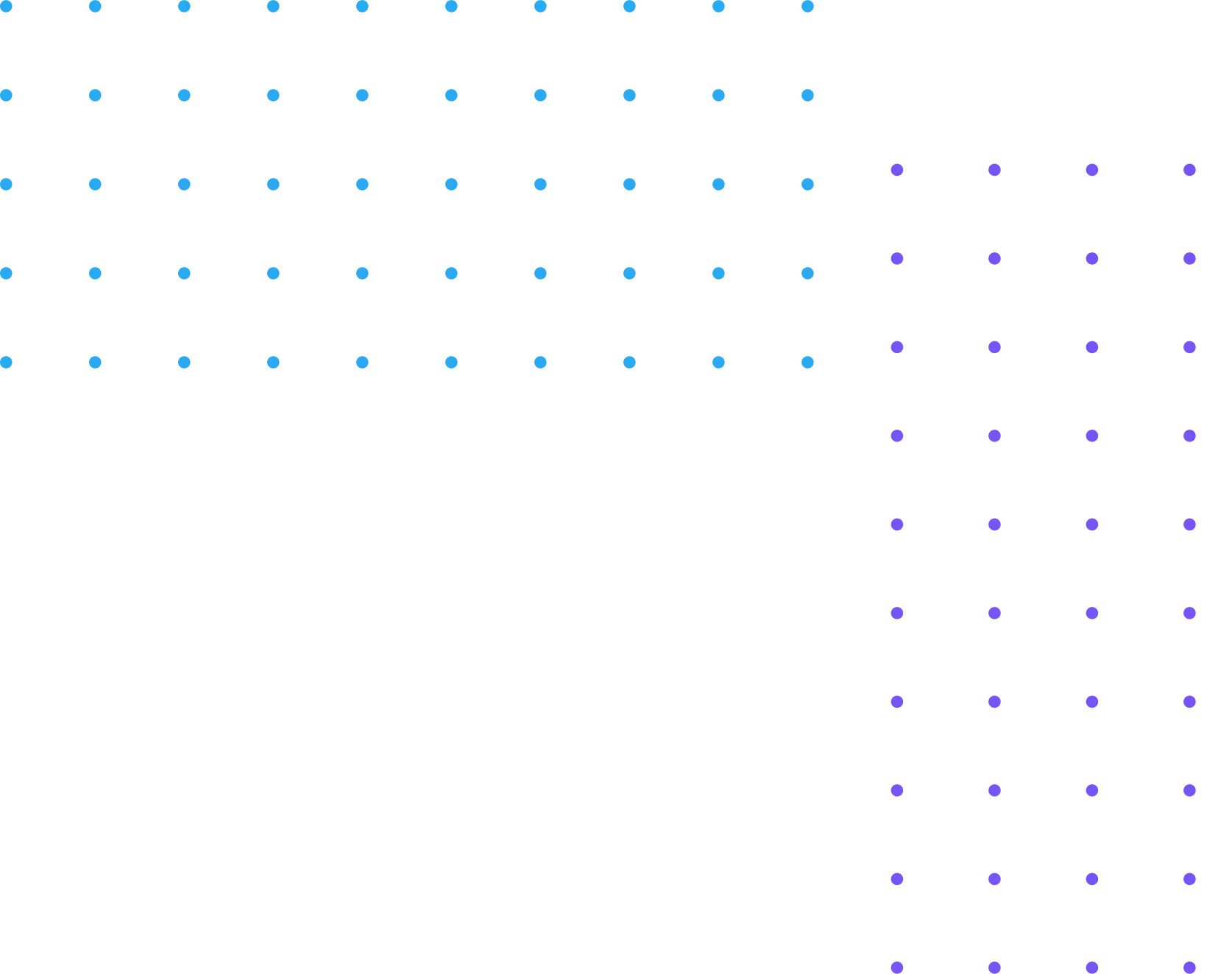

3D printed car lamp housing: car lamp is a vehicle lighting tool. The material requirements are the same as most guide light sources. It must be highly transparent. SLA light-curing high-transparency resin material can just meet the high transparency requirements of car lights. Post-processing polishing, the effect can be comparable to PMMA materials. After spraying and electroplating, it can also be used for the internal components of car headlights.

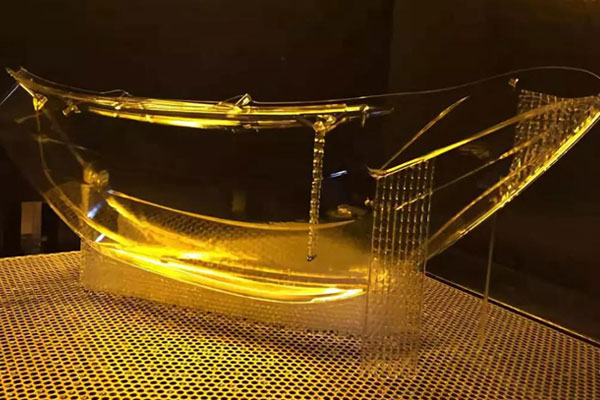

3D printed brake calipers: In the industrial manufacturing process, the design of products will be affected and restricted by the manufacturing process. Designers cannot let go of imagination and pursue the most ideal product effects. With the perfect combination of 3D printing technology and traditional craftsmanship, industrial manufacturing has become simpler and more efficient; for additive manufacturing, any product data can be achieved through 3D printing, which is important for industrial manufacturing. The field has brought revolutionary changes.

3D printed implants: The artificial joints used in traditional clinical practice will experience wear and tear of the prosthesis, bone dissolution around the prosthesis, and aseptic loosening of the prosthesis. After the introduction of 3D printing technology, the implant structure is more suitable for human trauma. , Better achieve “tailor-made”, can effectively solve the above problems. Taking advantage of 3D printing in manufacturing complex structures, printed porous implants can also promote muscle and soft tissue growth.

3D printed shoes: Consumer products are the most commonly used products in our daily life. The combination of 3D printing and this type of product allows us to constantly experience new consumer black technology. This pair of 3D printed shoes is personalized and can be customized perfectly. Compatible with the user’s sole, the complex sole support design can greatly reduce the impact, and compared with traditional shoes, 3D printed shoes have less waste of raw materials and have huge environmental protection potential.

3D printing teaching model: With the gradual introduction of 3D printing technology in the teaching field, many models that are not easy to display can be vividly introduced into the classroom through refined printing and post-processing techniques. Intuitive display can effectively reduce communication costs. Improve learning effect. And compared with traditional hand-processing and plaster molds, 3D printing teaching models are more fidelity and cheaper.`

Cultural Relic Restoration: Recently, a three-dimensional printer was printing a bronze model in the emergency protection room for small traces at the archaeological excavation site at Sanxingdui site. On the same day, at the six newly discovered archaeological excavation sites of the Sanxingdui cultural “sacrifice pit”, the on-site staff introduced that the three-dimensional printing technology was used at the archaeological excavation site of the Sanxingdui site to digitally scan the exposed parts of the larger artifacts at the excavation site. Print out the model to cover the surface of the object as a protective shell, so as to provide better protection for the cultural relics during the extraction process.

Electronic components: The electronics industry is a fast-developing industry. The iterative development of electronics and information technology and the emerging needs of the market are driving this industry to constantly innovate. The electronics industry also applied 3D printing technology earlier, and many electronic accessories today are manufactured with 3D printing. With the breakthrough progress of printable materials, 3D printing will bring more surprises to the electronics industry.

3D printing robot: integrate 3D printing technology into robot production to help customers optimize design, reduce production cost and development cycle. Using the high-precision advantages of 3D printing can provide more possibilities for robot design. This helps companies to quickly verify in production iterations to quickly adapt to market needs.

3D printed solar panels: Compared with traditional solar panels, 3D printed solar panels have unparalleled technical advantages: production will be liberated, decentralized, and users can become their own masters; in terms of supply chain, this This model also realizes ready-to-use, fully-balanced supply and demand, and solves the situation of overstocking and short supply.

PTJ focuses on the application of 3D printing technology in different industries, and uses technology to empower the industry to promote industrial upgrading. Processing projects include: 3D printing, 3D scanning, 3D design, laminating, CNC rapid prototyping, etc. Among them, 3D printing materials include: high temperature resistant photosensitive resin, transparent parts, nylon parts, metal parts, red wax, etc.; small batch production materials for laminated films include ABS, nylon, and POM soft rubber (ranging from 40 degrees to 90 degrees). The scanning machine adopts imported scanner with high precision and fast speed

- (1) Equal material manufacturing refers to the production of products through casting, forging, welding, etc. The weight of the material is basically unchanged, and it has a history of more than 3,000 years.

- (2) Subtractive manufacturing refers to the use of turning, milling, planing, grinding and other equipment to cut materials to achieve the design shape after the industrial revolution. It has a history of more than 300 years.

- (3) Additive manufacturing, that is, 3D printing, refers to the use of light curing, selective laser sintering, fusion accumulation and other technologies to accumulate materials little by little to form the required shape.

Whether it is equivalent material manufacturing or subtractive material manufacturing, in the industrial manufacturing process, product design will be affected and restricted by the manufacturing process. Designers cannot let go of imagination and pursue the most ideal product effects. With the perfect combination of 3D printing china technology and traditional craftsmanship, industrial manufacturing has become simpler and more efficient; for additive manufacturing, any product data can be achieved through 3D printing, which is important for industrial manufacturing. The field has brought revolutionary changes.

GET IN TOUCH OR GET A QUOTE

PTJ 3D Printing

Mobile WhatsApp WeChat:

+86 8288 6112

+86 152 1709 1354

Email: [email protected]

Address: Dongguan City, Guangdong Province, China.