Metal filament greatly expands the use of metal 3D printing for a wide range of professionals who are too expensive to use the technology. Today, wire printing, also known as fused metal deposition (BMD) or metal deposition modeling (MDM), is suitable for making small replacement parts or injection molds. Fabricating metal parts from wire is not only 90% cheaper than other single-piece or low-volume metal 3D printing techniques, but it avoids the safety concerns associated with using metal powder and laser metal 3D printing, offering the same design freedom and very similar part quality . So how do you get 3D printed metal parts easily and affordably?

Today, more manufacturers of desktop fused deposition modeling (FDM) 3D printers, including Anycubic, have introduced metal printer profiles that allow users to print with metal filament on their affordable machines. Other FDM printer manufacturers, such as Ultimaker, BCN3D and zortrax, have introduced related kits suitable for metal printing, including profiles, filaments and nozzles. The third category of desktop 3D printers are those dedicated to metal filament, such as Raise3D’s Forge1 and Markforged’s Metal X.

The following sections describe the unique features and capabilities of wire printing, explaining how to print with wire and the mechanical properties that can be achieved. In addition, some wire 3D printers are available at the end of this article.

What is wire?

The metal filament used for printing consists of a plastic base into which metal particles are uniformly infused, a composite filament that produces strong, chemically resistant metal parts with a high solids content (98%+). Unlike other types of filament, metal filament also requires two to three steps of post-processing after printing, which involves removing the polymer from the print in a chemical solvent, then placing the print in a sintering furnace, where it Condensed into a metal part.

Be aware that we’re not talking about wire here just about wire that has metallic colors or decorative metals. Do not confuse these wires with those used for decorative purposes. Metal wire is simply called “aluminum” or “copper” depending on its color, and some are sold as PLA+metal, which contains only 5% to 40% metal powder. Some decorative wires, such as Formfutura’s MetalFil Classic Copper and ProtoPasta’s iron-filled PLA, contain a high percentage of metal powder (up to 80%), but only to simulate the look of metal. These don’t require any type of post-processing to remove plastic, but can be brushed, sanded, or polished to look and feel like metal.

Part designs, orientations, wall thicknesses, and support structures using metal filaments are different than any other filament. When printing on machines like the Ender 3 or Anet A8, be sure to follow the design guidelines of the filament manufacturer and printer manufacturer. Having the ideal slicer and printer settings on your machine ensures you get the most out of your material right from the start without having to experiment with bed temperatures and extrusion speeds, reducing filament waste. For example, a handful of FDM printer manufacturers (Makerbot, UltiMaker, Raise3D, Zortrax, and BCN3D) have certified Ultrafuse branded wire for use in their printers and have worked with Ultrafuse manufacturer BASF Forward AM to develop an ideal printer setup over time . But if the manufacturer has not tested or certified wire printing, users may experience print failures. Typically, wire starts at $150 for 500 grams.

Finding the right print speed can be a challenge if the printer manufacturer doesn’t offer one. Metal filament printing speeds are relatively slow and need to be adjusted according to the design of the machine and part, generally start printing at 30 mm/s or 40 mm/s, the same speed used to print nylon.

metal parts shrink

Note that the part shrinks during post processing (from 18% to 25% of its original volume, depending on the design and brand of filament) as the plastic material is removed from it and the remaining metal is compressed. This presents no small challenge when printing functional parts where dimensional accuracy is a priority. However, the shrinkage coefficient of the same wire material is consistent, so the initial CAD model can be properly scaled according to the shrinkage ratio, and the slicing software can automatically calculate it for you.

Forward AM’s Ultrafuse has a 16-17% shrinkage in the XY axis and a 19-20% shrinkage in the Z axis. Using Filamet brand wire from The Virtual Foundry, you can plan to shrink your prints by about 5% for copper and bronze and 10% for steel using the company’s published debinding/sintering process. Overall, the normal shrinkage rate is 7-10%, the company said. The final part is 80-85% dense, but the part can be sintered for longer, which means more shrinkage and higher density.

The printer manufacturers below offer debinding and sintering units as a package, and they provide workflow software that helps ensure your parts meet design guidelines and optimize all print and sintering settings. For filaments that skip the debinding stage, such as Virtual Foundry and Nanovia, the green body must be embedded in alumina powder during the thermal debinding stage, another material to purchase, but less expensive than the debinding unit.

Wire design

First, according to the wire printing guidelines developed by MakerBot (now part of UltiMaker), the model aspect ratio should be kept under 3:1 and the wall aspect ratio should be kept under 6:1 to prevent printing during debinding and sintering. collapsed or deformed. Also, according to MakerBot, print parts as flat as possible and add as many supports as possible to improve part survivability during debinding and sintering. Part collapse and warping can be significantly reduced through the strategic use of part positioning and support structures during the printing and post-processing stages.

need post-processing

3D printing wire does not produce strong or usable metal parts right off the print bed. In fact, the initial print is called a bisque, and at this point the part is very brittle and has no metallic features, so post-processing is necessary. After printing, the green body undergoes debinding, a process that uses heat or solvents to dissolve plastic or adhesive components. This step creates opening channels throughout the part. (There are exceptions, Filamet brand wire does not require chemical degreasing, but uses the heat of a furnace to remove the plastic binder. 3D printer manufacturers Desktop Metal and Rapidia (which use metal paste instead of filament) also have a 3D printer that skips the degreasing step. Printer to sinter two-step process.)

The degreased part is then sintered in a furnace, which uniformly heats the part to just below its melting point, removing any residual binder and melting the metal particles to form a dense part. Most wire materials can be sintered in common kiln hardware as long as it can maintain the sintering temperature for a few hours.

Outsourced debinding and sintering

There are already several manufacturers on the market that offer a set of machines, including printers, washing or debinding machines, and sintering furnaces, capable of carrying out the entire process in-house and using one piece of software to coordinate or automate the process. It is not necessary to own a debinding machine or a sintering furnace to create 3D printed metal parts. Users can send parts for professional post-processing. Two brands, Metal Ultrafuse and The Virtual Foundry, offer recommended third-party services that will complete your metal parts and send them back. More on-demand 3D printing providers are also offering the service. In Europe, as long as you use Ultrafuse brand stainless steel wire, you can send the part along with the STL file to Fastparts for debinding and sintering. In the US, you can turn to Matterhackers for your Ultrafuse parts.

Mechanical properties of metal parts made of wire

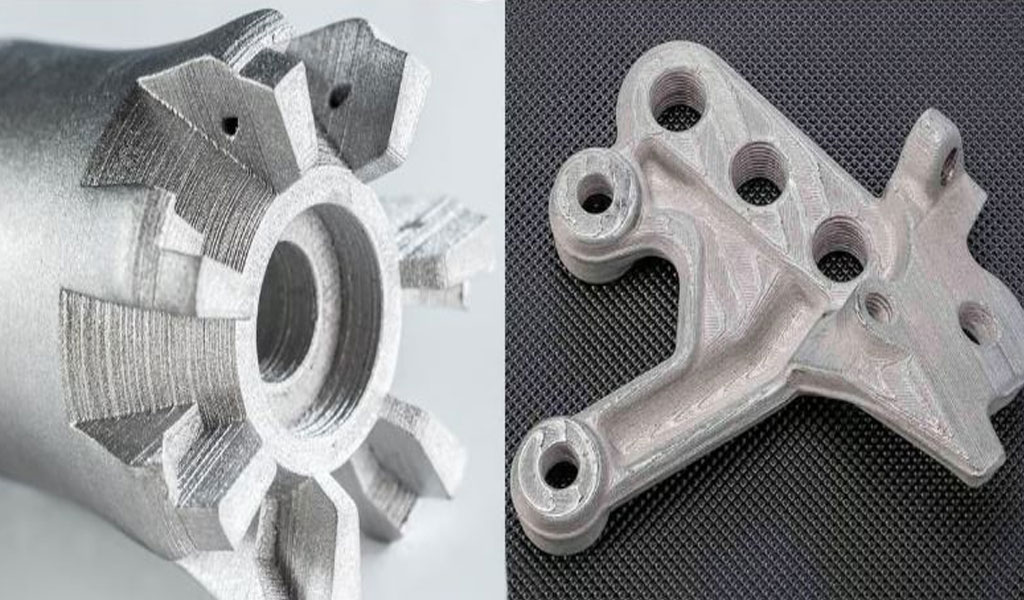

Metal filaments are stronger than almost all plastics used in standard desktop FDM 3D printing, and the final part has metallic properties. Typical applications include metal nozzles, gears, medical tool prototypes and valves. Be aware that parts made of wire are generally not designed to withstand very high stresses. Although 3D printing with wire may not be suitable for applications with strict requirements, it is extremely economical to produce dense metal non-critical parts on FDM machines.

Properties of Wire 3D Printed Parts

Research by Forward AM has shown that when properly 3D printed, metal parts produced using Ultrafuse 316l stainless steel wire have a tensile strength of 561 MPa in the XY (planar) direction and 521 MPa in the ZX (vertical) direction, while The same part manufactured using metal injection molding had a tensile strength of 540 MPa in both directions. The yield strength, or stress corresponding to the point at which the material begins to deform, was significantly higher for the 3D printed parts (251 MPa for XY and 234 MPa for ZX) than for the molded parts (180 MPa).

A recent study found that when the ply direction is parallel to the stretching direction, the strength of the part is much lower than when the ply direction is perpendicular to the stretching direction. The study was conducted not with Ultrafuse or Filamet, but with a 60% metal and 40% plastic binder material created for the experiment. Ultrafuse’s technical data shows similar XY and YZ strength values.

3D printed component design and print orientation play a crucial role. To reduce the risk of mechanical instability, Forward AM recommends performing a “Dress Stability Simulation” prior to printing, following their online guide. This provides an estimate of internal stresses to assess the structural integrity of the part during debinding, and also provides visual guidance on which structural features are at risk. This sintering simulation is provided as a service through Forward AM’s virtual engineering services. Using such tools, users can determine whether wire printing is best for your part.

top wire

Ultrafuse by Forward AM

- BASF Ultrafuse 316L stainless steel: $500 per 3 kg spool

- BASF Ultrafuse 17-4 PH Stainless Steel: $350 per 3 kg spool

Forward AM’s parent company, BASF, is one of the world’s largest chemical companies. Their metal-infused filament is called Ultrafuse and is made of 316L stainless steel and 17-4 PH stainless steel. Both filaments contain 80 percent metal powder and a proprietary polymer-based binder. Ultrafuse 17-4 PH, also known as Type 630, is a chrome-copper hardened stainless steel that is magnetic and maintains good mechanical and corrosion resistance up to 315 °C. The Ultrafuse 316L supports a wide range of applications including tooling, jigs and fixtures, low volume production, functional parts and prototypes. The wire doesn’t come cheap, costing around $129 per kilo, the Ultrafuse 316L costs around $465 for a 3kg spool, and $349 for the Ultrafuse 17-4 PH, also available in 1kg spools.

Although this filament is much more expensive than standard polymer 3D printing filaments, it is less expensive than many carbon fiber reinforced PA filaments and greatly reduces the cost of producing small to medium metal parts. Depending on the design and size of the part, it can be less expensive than any other metal AM technique. Printing with the Ultrafuse 316L is 1.4 to 2 times cheaper than printing with most metal powders on industrial metal printers.

- Diameter: 1.75mm, 2.85mm

- Spool size: 1 kg, 3 kg

- Material Composition: 80% 316L Stainless Steel; 17-4 PH Stainless Steel with 20% Thermoplastic Adhesive

- Nozzle temperature: 220-245°C

- Bed temperature: 90-100℃

- Cooling: not required

- Print speed: 30-40 mm/s;Bottom plate: glass bed with glue sticks;Nozzle: Any wear-resistant nozzle (steel, ruby, etc.)

- Sintered density: 7.85 kg/m 3 (Ultrafuse 316L); 7.6 kg/m 3 (Ultrafuse 17-4 PH)

- Average shrinkage: X & Y 16%, Z 20%

- Recommended initial scaling factors: X & Y 120%, Z 125%

- Technical Data Sheet: Ultrafuse 316L, Ultrafuse 17-4 PH

Filamet by The Virtual Foundry

- The Virtual Foundry 316L stainless steel: $700 per 3 kg

- The Virtual Foundry 17-4 PH stainless steel: $900 per 3 kg

US-based materials manufacturer The Virtual Foundry specializes in wire and offers nine Filamets, including 316L stainless steel, Inconel 718-34 F steel, titanium, copper, aluminum and, new for 2023, H13 tool steel. The company’s 316L stainless steel wire is about 85 percent metal and can be used in any FDM printer, but requires some additional equipment. For example, to print with the company’s 316L, you’ll need a FilaWarmer to warm up the filament.

Filamet can print with slightly lower nozzle temperatures (205-235 °C) and much lower bed temperatures (40-50 °C). Another thing to consider is that the TVF’s filament requires a 0.6mm stainless steel nozzle, while you can use the more standard 0.4mm diameter nozzle for the Ultrafuse. Due to Filamet’s high metal content, it breaks more easily than standard PLA. TVF recommends hanging the spool directly above the printer for a direct drive extrusion setup, or near or below it for a Bowden setup.

Nanoe’s Zetamix

- Zetamix in Nanoe 316L stainless steel: $1,500 per 3 kg

- Zetamix in Nanoe H13 Steel: $1,500 per 3 kg

French material manufacturer Nanoe provides 316L stainless steel wire and H13 tool steel wire, the binder of the two filaments is about 52% to 55% metal, so they can print at a much lower nozzle temperature than other brands, you can get Final parts with a density of 90% to 91% can expect shrinkage of 16% to 21.3%. Global distributors offer 500 grams of 319L stainless steel and H13 tool wire for just under $300 per kilo.

- Diameter: 1.75mm, 2.85mm

- Spool size: 500g, 1kg

- Material composition: 55% 316L stainless steel or 52% H13 steel

- Nozzle temperature: 180 °C

- Bed temperature: 30 °C

- Cooling: not required

- Print speed: 15 to 50 mm/sec, depending on part shape

- Nozzle: 0.6 mm or larger, standard stainless steel

- Recommended initial scaling factors: X & Y 120%, Z 125%

- Technical data sheet: 316L, H13

Nanovia’s Mt 316L

●Mt 316L Stainless Steel: $900 per 3 kg

French material manufacturer Nanovia offers 316L stainless steel wire with low carbon content, and the printed parts can be sintered directly without any prior chemical debinding step. It costs around $150 for 500 grams. The Mt 316L filament allows for the printing of dense stainless steel parts using standard 3D printers, which can then be sintered without chemical debinding. Nanovia claims that the result after sintering is a 100% stainless steel part.

- Diameter: 1.75mm, 2.85mm

- Spool size: 500 grams

- Nozzle temperature: 170 °C – 100 °C

- Bed temperature: 40 °C – 60 °C

- Print speed: from 20 to 40 mm/sec, depending on the shape of the part

- Nozzle: 0.6 mm or larger, standard stainless steel

- Shrinkage rate: 10% – 15%

- Technical data sheet: 316L

Wire 3D Printer

Markforged Metal X Gen2

Markforged launched the Metal X in 2017 and it remains one of the preferred metal 3D printing solutions for thousands of customers around the world. The Metal X is a dual-extruder 3D printer with a heated chamber that can achieve layer heights of 50 microns. Unlike other printer manufacturers, Markforged offers six metals in its proprietary range, including copper and Iconel. With copper you get a 98% dense metal part with an elongation at break of 45% and an ultimate tensile strength of 193 MPa.

Removing supports is a major problem in metal 3D printing, and Markforged offers a relatively unique solution, between the print and the support, both printed in metal, is a thin ceramic release layer that can be quickly removed without tools Easily pop off the support.

Markforged offers the debinding unit Wash 1 and the sintering furnace Sinter 2, enabling the entire production of metal parts in-house. Wash-1 dips the green part in a special liquid that removes the main binder material and leaves the part semi-porous so that the remaining binder can burn off during sintering. With temperatures up to 1300°C, the Sinter 2 furnace can sinter a wide range of commercial grade metals from the skim state into fully dense metal parts.

The all-metal 3D printing system is powered by the company’s cloud-based Eiger workflow software, which enables users to store “digital parts” that can be printed on any Metal X printer in any location. Eiger also has part simulation capabilities to verify part performance and print settings before printing. The Metal X retails for around $99,000, with the three aforementioned units priced around $200,000. Materials range from $150 to $300 per 200cc spool.

Markforged Metal X:

- Build volume: 250 x 220 x 200 mm

- Print chamber: heating

- Print bed: heated, vacuum-sealed print plate, automatic bed leveling

- Minimum layer height: 50 microns

Desktop Metal Studio System

Desktop Metal is one of the pioneers in metal deposition 3D printing, bringing down the price and increasing the ease of use of metal 3D printers. Its Studio System, which debuted in 2016, can produce parts up to 98% denser, similar to castings. All Studio Systems materials are supplied with a data sheet detailing expected mechanical properties. Desktop Metal’s copper parts boast an elongation at break of 37% and an ultimate tensile strength of 193 MPa.

Following the release of the Studio System, Desktop Metal introduced new technology, creating a two-step “printer to sinter” process that eliminates the debinding step. Using a proprietary material formulation allows printing parts directly into the furnace without a solvent debinding stage, saving time, solvent materials. As one of the pioneers of this technology, Desktop Metal laid some of the groundwork for other printer manufacturers to follow. Its solution includes a printer, proprietary materials, proprietary software, its own sintering furnace, and a detachable stand with a ceramic interface material between the support structure and the part, allowing the part to be easily disassembled by hand.

About $275,000 for the Studio System 3D printer and furnace:

- Build volume: 300 x 200 x 200 mm

- Layer height (green state): 50 microns

- Heated bed: 70 °C

- Maximum build weight (green status): 6.5 kg

Raise3D Forge1

Raise3D’s Forge1 is a professional large-format metal 3D printer that is part of the company’s MetalFuse solution, which includes the printer, D200-E debinding unit and S200-C vacuum sintering furnace capable of reaching 1500°C. With these three machines, Raise3D can provide a streamlined workflow for in-house metal part production using software that automatically calculates print shrinkage so that final dimensions after debinding and sintering are accurate and fit for use. Forge1 printers boast dual extruders, self-leveling beds, run-out sensors, and HEPA filters with activated carbon. The MetalFuse system prints with BASF Forward AM Ultrafuse stainless steel. The dual extruder prints with BASF’s Ultrafuse support layer, currently only available in Europe, an alumina material used for “layer isolation”. In other words, it makes the separation support the separation layer between the support and the print after sintering.

- Build volume: 300 × 300 × 300 mm

- Filament diameter: 1.75 mm

- Layer height: 100 microns

- Bed temperature: 120 ºC

Printer maker BCN3D is launching a Metal Pack in November 2021, which includes Ultrafuse stainless steel wire (316L and 17-4 PH), Magigoo adhesive, software and two hot ends for about $1,200. BCN3D also provides specific design guidelines and process requirements for metal parts. The Metal Pack is available not only for the W50, but for the entire Epsilon family of 3D printers (W50SC, Epsilon W27 and W27SC), offering a variety of sizes and price points for getting started with metal part production.

Metal Pack is designed for the production of spare parts, functional prototypes and tooling, mainly for the pharmaceutical, food, automotive, aerospace and manufacturing industries. Parts produced by this process behave nearly identically to those produced by metal injection molding or CNC, and offer an office-friendly solution with greater design freedom.

BCN3D Prints Metal Contour in its Stratos Slicer avoids internal tension of the printed part during the printing process. After printing, the debinding and sintering process is performed externally through the current Forward AM network of authorized service providers. Outsourced debinding and sintering costs around $50 to $80 per kg. The Epsilon W50 printer alone costs $8,500, while the Epsilon W27 is $7,000.

Epsilon W50

- Architecture: IDEX (Independent Dual Extruder System)

- Build volume: 420 x 300 x 400 mm

- Heated bed: 120 ºC

Since the release of the printer profile for the Ultrafuse 17-4PH in 2021, UltiMaker has enabled users to print complete metal parts on its S5 machines. In 2022, Ultimaker introduces a brand new metal 3D printing kit: the Metal Expansion Kit. Andrea Gasperini, Product Manager at Ultimaker, said: “The Ultimaker Metal Expansion Kit is especially suitable for printing off-the-shelf parts such as tools, jigs and fixtures, replacement parts, functional prototypes and auxiliary components. process access.

- Architecture: Dual Extruder

- Print volume: 330 x 240 x 300mm

- Nozzle temperature: 180-280℃

- Layer resolution: 20 microns with 0.25 mm nozzle

- Price: $8,000

Zortrax M300 Dual

Zortrax is one of the latest FDM 3D printer manufacturers to partner with BASF Forward AM to create a printing peripheral and accessory kit that will enable the M300 company or its Edural 3D printers to print complete metal parts. The Zortrax full metal kit supports 3D printing models using two of the most commonly used steels: 316L surgical grade stainless steel and 17-4 PH hardened steel. To print with wire, you can replace the printer’s standard hot end module with the one included in the package, load the included print and support wires, cover the build platform with the included Magigoo Pro Metal Glue, and use the default Set up to print your Part-Suite.

- Build volume: 265 x 265 x 300

- Layer resolution: 90-290 microns

- Extruder: Double throw

- Maximum extruder temperature: 290°C

- Maximum bed temperature: 105°C

The characteristics of metal wire

Wire 3D printing is less expensive and can reduce the cost of small batches of metal parts by as much as 90% compared to individual production with traditional methods. Emerging technologies that use common metal raw materials (such as wire) and the same particles used in metal injection molding have the potential to eliminate the debinding and sintering steps in wire 3D printing and greatly reduce the price of raw materials. Metal wire is less dangerous than metal powder, but it is still made of metal powder, an expensive and energy-intensive product. Degreasers require solvents, and furnaces require large amounts of energy and gases, such as argon, which also add to environmental impact and cost.