Guide

- Anodizing vs. Painting: An In-depth Analysis

- 9 Types of 3D Printed Metal Copper Techniques

- 3D Printing Materials and How to Choose the Right One?

- What Is Micro Manufacturing Technology

- Wire 3D Printing: Process, Filament, Printer and Features

- Uncover The Mystery Of CNC Machining

- Huazhong University of Science and Technology has made new breakthroughs in ultrafast laser 3D printing of fine and complex semiconductor micro-nano structures

- In 2025, there will be more than 600 metal 3D printing equipment serving China’s aerospace and other fields

- Looking at the development trend of 3D printing from Formnext 2021

- 3D printed prototype silica gel molds, realizing small batch production of industrial products

- Global architectural 3D printing inventory, no need to move bricks to build a house

- The latest application cases of 3D printing in aviation

- 3D printing everything? Japanese media: Printable buildings, parts, organs and even food…

- 3D printing provides emergency production of anti-epidemic products, global anti-epidemic

- Common Technology List Of Metal 3D printing

Case Studies

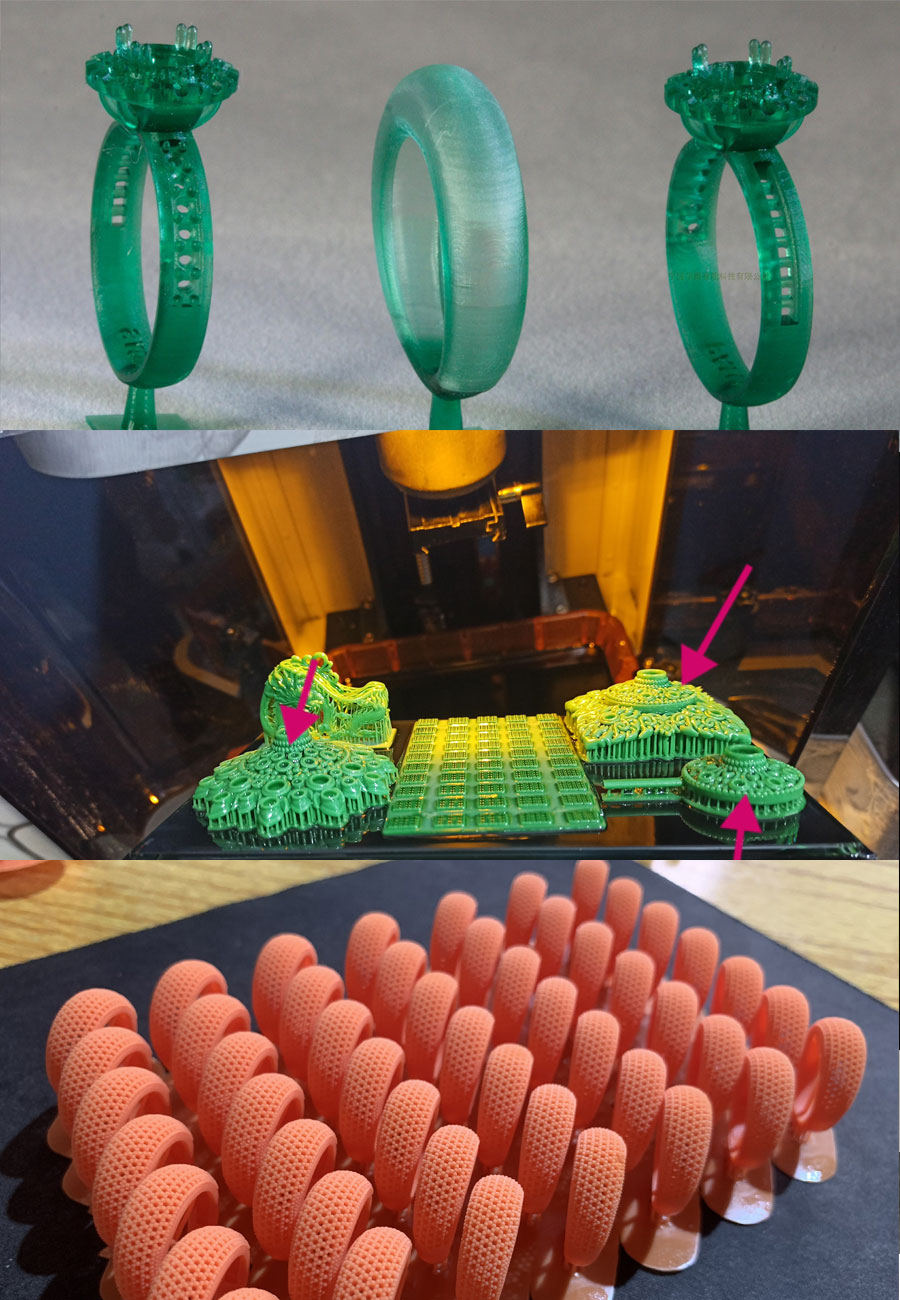

3D Printing Jewelry And Accessories

3D printing is continuation of smart jewelry design digital manufacturing

3D Printing In Jewelry Field

In recent years, 3D printing technology has developed rapidly, and breakthroughs have been made in innovative applications in professional fields such as jewelry and accessories. The combination of 3D printing, virtual reality (VR), augmented reality (AR) and other technological means has become the personality of the jewelry and accessories industry. Digitalization, digitization, and intelligence have created favorable opportunities. With the development of 3D printing technology in the jewelry and accessories industry, the use of digital technology to shorten the production process, broaden the design inspiration, and make products present unprecedented artistic visual effects. 3D printing technology is gradually becoming the innovation engine of intelligent manufacturing in the jewelry and accessories industry.

Jewelry usually needs three key points in the development of the rapid prototype of the final product needed to match:

- – First of all, fine details are necessary to correctly portray the desired product due to the typical small size of jewelry products.

- – Secondly, the problem of prototyping with a smooth surface becomes crucial. The main reason for this is to appreciate the beautiful part, but it also requires post-processing (such as silicon molding, jewelry molds, processing using VLT rubber, and others).

- – Finally, tolerances are critical, when producing prototypes for the jewelry market as small parts require an almost perfect match to the product required by the CAD drawing. The thickness of the film layer of our molding technology is 16μ, its special smooth surface, and its printing accuracy provide a solid and attractive solution.

Jewelry And Accessories Industry is ever evolving, one thing hasn’t changed at all: The traditional jewelry manufacturing process needs to go through multiple processes such as plate lifting, mold pressing, waxing, and mold repair. 3D printing technology is different from traditional manufacturing methods. It is a continuation of the digital manufacturing of smart jewelry design. Traditional manufacturing belongs to “subtractive manufacturing”, while 3D printing technology is “additive manufacturing”, which uses metal or plastic and other related materials to compose objects by accurately adding materials layer by layer according to computer digital models.

So customized 3D printing services for jewelry and accessories is very important in the jewelry manufacturing field, also custom jewelry or accessories can make your products more competitive in the market.

Table of Contents

Why Choose PTJ Jewelry 3D Printing Service

PTJ meets or exceeds the quality standards of the world’s most demanding industries with our state of the art equipment and quality standards. Our precision and productivity is made possible by our ultimate success factor: the presence of skillful, knowledgeable PTJ experts in Jewelry 3d printing and more additive manufacturing parts.

- No minimum order quantity

- Metal or plastic 3D printed prototype and production parts in 7-10 days

- Precision custom 3D printing parts at affordable prices

- Online free quote in the shortest time

- Single prototypes or complex shapes are both allowed

- A wide selection of metal or plastic materials

- Commercial and industrial-grade 3D printers

- Cooperative supplier assistance project

- Provide a quick solution for small batches of complex prototypes

- Provide a quick solution for small batches of complex prototypes

- We provide with our partner

- 3D printing services for metals and plastics

- Meet the rapid needs of complex prototype designers

3D Printing Technical Solutions In The Jewelry Industry

- - One is the 3D printing technology that directly prints precious metal entities, that is, laser sintering technology. It is an additive manufacturing process based on 3D CAD design. It uses a 3D CAD file as a digital information source and energy setting, and uses a high-power laser beam to sinter a very small metal powder layer into a technical solution for a three-dimensional part.

- - The other is to use 3D printing wax model (Projet technology) and resin model (DLP/SLA technology), using the lost wax casting process. This solution improves the speed and accuracy of the most critical wax mold making process in the traditional jewelry manufacturing process, and can achieve rapid mass production. Whether directly or indirectly used for jewelry manufacturing, 3D printing technology will simplify the current jewelry production process and promote the development of the industry to the direction of personalized, refined, and digital intelligent manufacturing.

3D printing precious metals (SLM technology/SLS technology) technology is mainly used in aerospace, high-precision and cutting-edge manufacturing and other high value-added fields. Directly using expensive precious metal 3D printers to print jewelry is cost-effective and not suitable for mass production .

Therefore, the current jewelry industry mainly applies 3D printing wax mold technology, using lost wax casting technology, the process accuracy can reach micrometer level, through professional 3D design software system, online interactive system, material library, model library, display platform, etc. , Use the database resources in the system to independently select and design jewelry, quickly generate product elements, after the product order is generated, use a high-scoring 3D printer to print into a wax model, and then use the lost wax casting process for production, which can restore the design style in the smallest detail. , Respond quickly to market demand.

The Advantages Of 3D Printing Jewelry

- – Digital production is exquisite and accurate, which solves the production problems of complex structures. Compared with traditional manufacturing, complex structures cannot be completed by hand, and 3D printing technology can make up for this artificial “fault”. 3D printing technology uses computer technology to establish three-dimensional models, and import system digital production on demand and quantity. It can quickly produce high-precision and complex craft jewelry that cannot be achieved by traditional manufacturing, which is conducive to the development of advanced customization, seize the high-end market, and improve customer satisfaction.

- – Reduce labor and production costs. 3D printing omits prototyping, mold making and other related steps, greatly reducing the production period and material costs, and has the advantages of simple operation, rapid prototyping, high precision, saving materials, and reducing losses. At the same time, 3D scanning and CAD reverse design software are coordinated. The design efficiency is greatly improved, and it can also be iterated quickly to enhance product competitiveness.

- – Shorten the production cycle and quickly respond to the market. The traditional jewelry manufacturing industry is slow to respond to market changes. The supply chain usually takes 5 to 10 months to respond to market enthusiasm. Customized platform system orders, through the establishment of a three-dimensional model, real-time modification of data deviations, confirmation of rendering effects, using 3D printing technology to quickly produce and market, and truly achieve zero inventory sales.

- – Significantly improve the intelligent production level of the jewelry industry chain. 3D printing technology reduces the compression of the flattened links in jewelry design and production, and reduces the cost of jewelry design and production time at the same time. At the same time, VR technology allows consumers to better experience jewelry. Through AR hardware sensors and human-computer interaction technologies, Realize the confirmation of samples through virtual try-on and rapid mass production of 3D printing.

The Steps To 3D Printing Jewelry

As a new generation of design and production, 3d printing technology has brought extensive changes. Governments, scientific research institutes and companies around the world have vigorously promoted and developed 3d printing technology and its application in various industries. Especially in the jewelry industry, the use of wax spray 3D printing technology combined with paraffin wax casting technology has been widely used in complex and unique jewelry casting. However, the advantages of 3d printing technology with small forming limitations and high forming accuracy have not been fully utilized. The main reason is that the 3d printing technology is used to replace the traditional manual version, and the real reason is that the 3d printing technology has not been applied to the innovative design of jewelry with its advantages of small limitations and high forming accuracy.

In recent years, major breakthroughs have been made in digital manufacturing technology, and major breakthroughs have been made. Various markets have also emerged and gradually accepted 3d printing products. At the same time, the application of advanced 3D printing and digital technology has created unprecedented opportunities for Chinese jewelry. It follows that printing jewelry technology is divided into five steps:

- - Use a 3D printer with a high score ratio to print the design model into a wax model. This wax model has this saturated blue color, its density and surface characteristics are similar to traditional casting wax, and it is modeled and printed using a multi-jet design. It works by using several nozzles to sweep the melted wax across the structure building area and deposit it layer by layer on the aluminum platform. When the heated 3D printing material is sprayed on the build plate, the wax will solidify. Another wax with lower melting stability is deposited under the overhanging end of the design model as a support material. After printing, take the model out of the tray and put it in hot water to melt the supporting material.

- - Put the model into a container with liquid plaster. The gypsum is solidified, and the wax will melt in the furnace, and finally the gypsum mold will be obtained.

- - Pour the molten metal into the mold through pouring and harden it.

- - Break the plaster mold, and a new piece of jewelry is born

- - The jewelry is simply polished, and finally it is carefully cleaned and polished by hand.

3d-printing-china.com Jewelry Case Studies

3D Printing Personalized Jewelry And Ring

3D Printing Personalized Jewelry prototyping services in china. Materials worked with include ABS, acrylic, nylon, PET, polycarbonate, polyester, ...

3D Printing Personalized Bull Head Metal Jewelry

Jewelry Accessories Additive manufacturing (3D Printing) services for the utility, material handling, automotive, energy, construction machinery, ...

PTJ offers online 3D printing services for china rapid prototyping and production of non-metal and metal 3D printed parts at affordable prices.

- * Supports drawing uploads in file formats “.pdf”, “.jpg”, and “.png”.

- * Supports file uploading and loading of 3D (3D) CAD data “.igs” and “.step”.

- * Supports file uploading of two-dimensional (2D) CAD data “.dxf” and “.dwg”.

- PC

- ST-130

- PA 2200

- CoCrMo

- PA 3200 GF

- ABS M30

- Ceramic

- POM-like

- ULTEMTM 9085

- Paraffin Material

- Polyphenylsulfone

- Polyetheretherketone

- Soft Rubber Material

- Aluminum Filled Nylon

- High Ultra-Fine Plastic

- Mold Steel MS1

- NickelAlloy IN718

- Titanium Alloy Ti64

- White Photosensitive Resin

- Black Photosensitive Resin

- Transparent Photosensitive Resin

- Full Color Photosensitive Resin

- Micro-nano Material

- High Ultra-Fine Plastic

- Full-Color Gypsum Composite Material

GET IN TOUCH OR GET A QUOTE

PTJ 3D Printing

Mobile WhatsApp WeChat:

+86 8288 6112

+86 152 1709 1354

Email: [email protected]

Address: Dongguan City, Guangdong Province, China.