In the past half-century, the semiconductor industry has grown exponentially in accordance with Moore’s Law, leading human society into the era of electronic information, and having a revolutionary impact on the global economy and society.

However, in recent years, due to increasing production costs, technical barriers and limitations of the laws of physics, the traditional Moore’s Law has gradually come to an end.

Currently, most semiconductor manufacturing processes are facing the challenges of increasing chip performance and high integration density requirements in the future.

As a result, the development of emerging technologies such as artificial intelligence (AI), 5G/6G, and the Internet of Things (IoT) is facing a huge crisis.

Currently, there are two important development trends in the semiconductor field, which are considered to have the potential to solve the above challenges:

1) Traditional two-dimensional planar semiconductor devices and manufacturing processes are gradually developing towards three-dimensional integrated semiconductor devices and three-dimensional manufacturing processes;

2) Single silicon-based semiconductor devices and integrated manufacturing processes are gradually moving towards the integrated assembly of more semiconductor functional materials and high-density integrated manufacturing.

This is expected to expand a single integrated circuit into an integrated system with more functionality, such as optoelectronic fusion chips, intelligent integrated systems integrating sensing, computing, self-driving or self-actuating, etc.

Therefore, studying how to realize the manufacture of high-precision heterogeneous and heterogeneous three-dimensional semiconductor micro-nano structures and their functional devices is of great significance for the future development of higher-functionality and higher-density three-dimensional integrated systems.

Among the many 3D printing technologies, femtosecond laser 3D printing based on two-photon polymerization (TPP) has developed into a promising manufacturing technology due to the combination of true 3D manufacturing and sub-micron spatial resolution.

The research and development of functional photosensitive resin has always been a key aspect supporting the application of TPP technology.

However, the current conventional method for realizing functional photosensitive resins is to dope functional nanomaterials into organic resins, so as to realize 3D micro-nano structures with different functional properties.

However, such methods often require photosensitive resins containing high-loaded nanoparticle dopants, which will cause severe light absorption and light scattering effects during the TPP process.

This leads to inevitable particle agglomeration, micro-explosions and relatively low spatial resolution.

Therefore, the development of a high-performance photosensitive resin that can be used in 3D semiconductor nano-manufacturing is still an urgent problem to be solved.

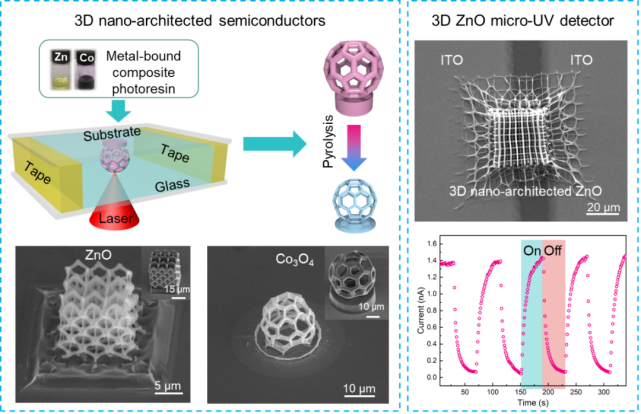

In response to this challenge, Professor Xiong Wei’s team from Wuhan Optoelectronics National Research Center of Huazhong University of Science and Technology used metal organic framework (MOF) precursors to develop a class of multifunctional and customizable metal bonding composite photosensitive resins.

Through TPP femtosecond laser 3D printing and subsequent pyrolysis process, the additive manufacturing of zinc oxide (ZnO) and cobalt tetroxide (Co3O4) 3D semiconductor micro-nano structures has been realized.

And prepared 2D and 3D miniature ultraviolet detectors based on ZnO, and discussed the possibility of using this technology to realize 3D semiconductor devices.

The multifunctional and customizable metal-bonded composite photosensitive resin proposed by Professor Xiong Wei’s research team can be prepared from a variety of MOF precursors and resin monomers (such as acrylates, epoxy resins and water-soluble monomers).

The metal ions are bonded to the acrylic acid groups through coordination bonds to form metal acrylic acid.

Due to the unsaturated C=C double bond of metal acrylic acid, it can be used as a monomer to achieve polymerization in the two-photon polymerization process.

Therefore, in the prepared polymer, the metal ion is covered by the organic long chain and attached to the organic long chain through the ion/coordination bond.

Therefore, the loss of metal ions is avoided during the development process, and the shape fidelity of the subsequent pyrolysis structure is ensured.

Based on this principle, the R&D team explored two MOF material precursors (ZIF-8 and ZIF-67), and prepared metal-bonded composite photosensitive resins containing zinc and cobalt, respectively.

Using TPP femtosecond laser 3D printing and pyrolysis process, ZnO and Co3O4 complex 3D microstructures with high spatial resolution (170 nm), high shape fidelity and high surface quality were prepared.

At the same time, it demonstrated the potential of this method in the preparation of 2D and 3D devices, and fabricated 2D and 3D miniature ultraviolet detectors based on ZnO.

This research has opened a way for the preparation of a variety of functional materials such as composite metal oxides and even metal micro-nano structures.

It is expected to promote the development of 3D integrated functional devices in the fields of micro-nano photonics, electronics, MEMS, and energy storage.

The related work is titled “3D printing nano-architecture semiconductor based on multifunctional and customizable metal combined with composite photoresist”,

Published in Advanced Materials Technology (DOI: 10.1002/admt.202101230), Dr. Jingwei Liu of Huazhong University of Science and Technology is the first author of the paper, and Professor Wei Xiong of Huazhong University of Science and Technology is the corresponding author of the paper.

The above research was supported by the National Key Research and Development Program (2018YFB1105400) and the National Natural Science Foundation of China (61774067, 61805094).

Source: Wuhan Optoelectronics National Research Center