Guide

- How to Calculate 3D Printing Price (SLS, SLA, SLM, MJF, FDM, ETC.,)

- Anodizing vs. Painting: An In-depth Analysis

- 9 Types of 3D Printed Metal Copper Techniques

- 3D Printing Materials and How to Choose the Right One?

- What Is Micro Manufacturing Technology

- Wire 3D Printing: Process, Filament, Printer and Features

- Uncover The Mystery Of CNC Machining

- Huazhong University of Science and Technology has made new breakthroughs in ultrafast laser 3D printing of fine and complex semiconductor micro-nano structures

- In 2025, there will be more than 600 metal 3D printing equipment serving China’s aerospace and other fields

- Looking at the development trend of 3D printing from Formnext 2021

- 3D printed prototype silica gel molds, realizing small batch production of industrial products

- Global architectural 3D printing inventory, no need to move bricks to build a house

- The latest application cases of 3D printing in aviation

- 3D printing everything? Japanese media: Printable buildings, parts, organs and even food…

- 3D printing provides emergency production of anti-epidemic products, global anti-epidemic

Case Studies

3D Printing Aerospace Parts

3D printing technology has given consumer products a new look and new vitality

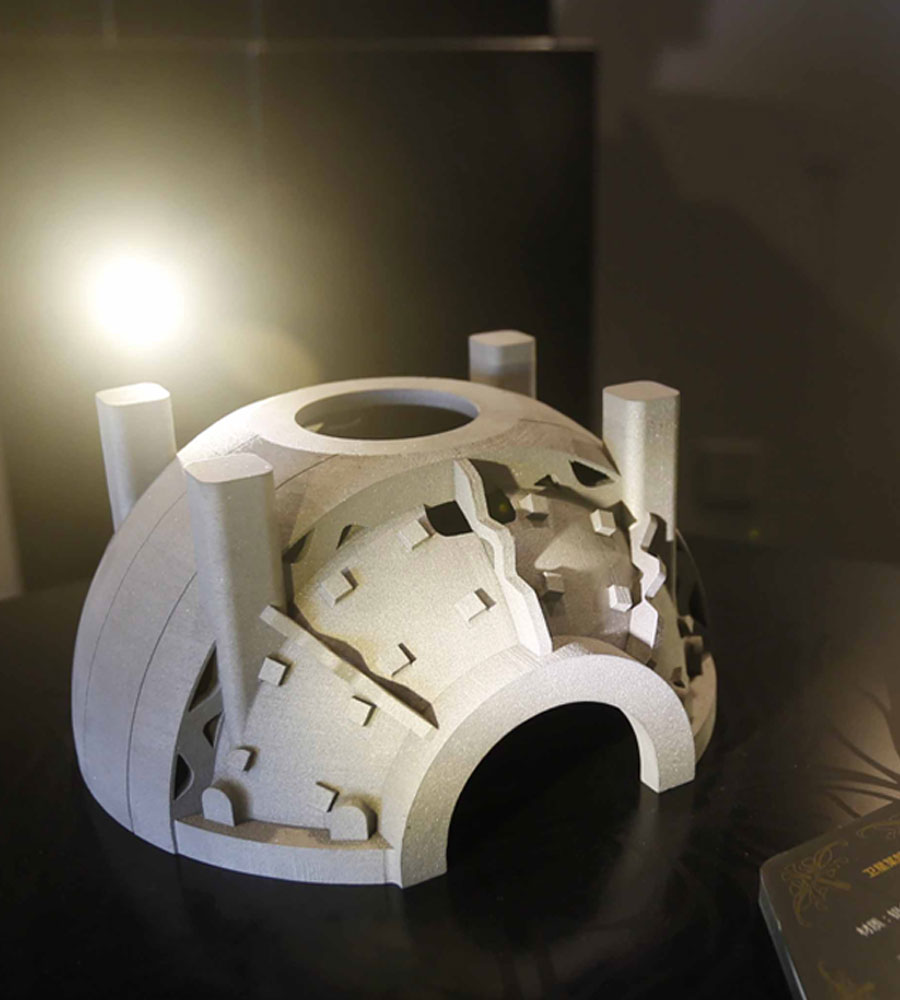

3D Printing In Aerospace Field

At present, as an important technology in the aerospace field, 3D printing is promoting the innovation of production process and production efficiency of aircraft model manufacturing. At the same time, 3D Printing technology is also changing the entire aerospace equipment supply chain to a certain extent. As a brand-new manufacturing technology, metal 3D printing technology has outstanding application advantages in the aerospace field and obvious service benefits. Mainly reflected in the following aspects:

- 1. Shorten the development cycle of new aerospace equipment

- 2. Improve the utilization rate of materials, save expensive strategic materials, and reduce manufacturing costs

- 3. Optimize the structure of parts, reduce weight, reduce stress concentration, and increase service life

- 4. Repair forming of parts

- 5. Cooperate with traditional manufacturing technology and complement each other

Traditional manufacturing technology is suitable for mass production of shaped products, while 3D printing technology is more suitable for the manufacture of personalized or refined structural products. Combining 3D printing technology with traditional manufacturing technology, taking advantage of each, give full play to their own advantages, and make manufacturing technology more powerful.

As the primary application field of metal 3D printing technology, aerospace has obvious technical advantages. However, in actual production, metal 3D printing also has its corresponding shortcomings. There are still many problems to be solved in its technical application. For example, 3D printing cannot adapt to mass production, cannot meet high-precision requirements, and cannot achieve high-efficiency manufacturing. . Moreover, a key factor restricting the development of 3D printing aerospace parts service is its high equipment cost, and most civilian fields cannot afford such high equipment manufacturing costs. However, with the continuous development of material technology, computer technology and laser technology, manufacturing costs will continue to decrease. By then, 3D printing will shine in the manufacturing field.

Table of Contents

Why Choose 3d-printing-china.com Aerospace 3DP Service

PTJ meets or exceeds the quality standards of the world’s most demanding industries with our state of the art equipment and quality standards. Our precision and productivity is made possible by our ultimate success factor: the presence of skillful, knowledgeable PTJ experts in Aerospace 3d printing and more additive manufacturing parts.

- No minimum order quantity

- Metal or plastic 3D printed prototype and production parts in 7-10 days

- Precision custom 3D printing parts at affordable prices

- Online free quote in the shortest time

- Single prototypes or complex shapes are both allowed

- A wide selection of metal or plastic materials

- Commercial and industrial-grade 3D printers

- Cooperative supplier assistance project

- Provide a quick solution for small batches of complex prototypes

- Provide a quick solution for small batches of complex prototypes

- We provide with our partner

- 3D printing services for metals and plastics

- Meet the rapid needs of complex prototype designers

What Aerospace Parts Can Be 3D Printed?

From the current application point of view, 3D printing technology has two main applications in the aerospace field: one is the direct and rapid manufacturing of complex components; the other is the rapid repair of components.

- – Compared with traditional manufacturing methods, 3D printing has many advantages in aerospace equipment manufacturing.

- – The shape and internal structure of key parts of aerospace equipment are usually complex, and traditional manufacturing processes such as casting and forging are difficult to accurately process, while the processing process of 3D printing is not limited by the complexity of the parts;

- – Aerospace equipment has very strict requirements on the performance and composition of materials. 3D printing technology can easily process difficult-to-process materials such as high-melting and high-hardness superalloys and titanium alloys, and the materials are relatively fully utilized in the 3D printing process. , Can significantly reduce manufacturing costs;

- – The near parts after 3D printing are very close to the requirements of the finished product, and there is no or only a small amount of subsequent processing, which can effectively shorten the production cycle of parts and components, and meet the rapid response requirements of aerospace products.

In the aerospace field, the cost of major equipment is expensive. If parts are damaged or parts are out of size during use, it will cause great economic losses. At this time, it is a good choice to use 3D printing technology to repair the damaged parts of the parts, so that the overall equipment can be put into use quickly.

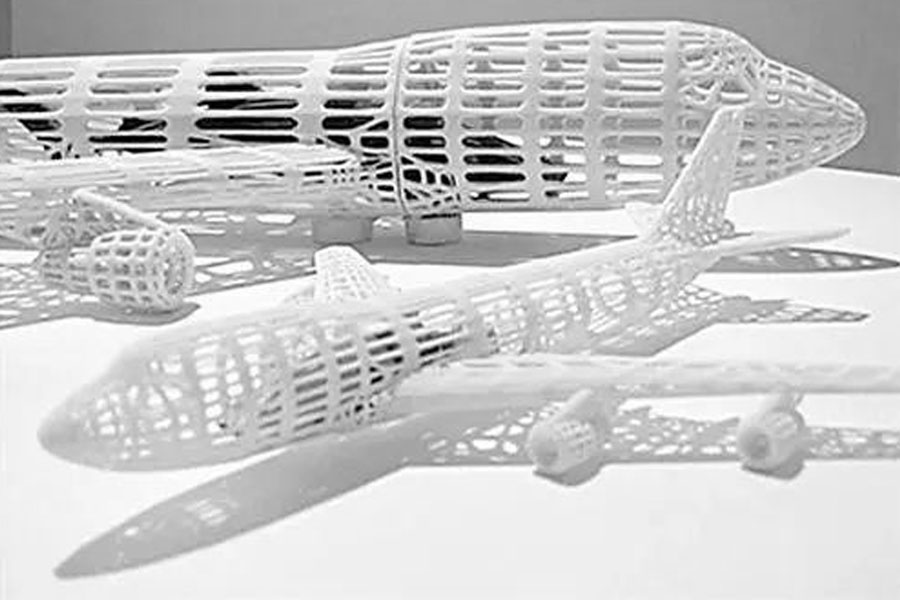

Metal 3D Printing For Aerospace Parts

Aluminum, titanium, Hastelloy and Inconel superalloys are widely accepted by aircraft manufacturers, but when parts are made by 3D printing, they are expected to be subject to stricter scrutiny, especially when new alloys may be used. All of these Extensive and rigorous testing is required before flight use.

With the rapid development of modern aircraft manufacturing, whether working on a commercial, military or space-related project, Metal 3d printing technology has become one of the key technologies for aerospace manufacturing. The advancement of aerospace 3d printing processing technology has changed the concept of aircraft design, and the design of aerospace parts has become more integrated and complicated. Aerospace parts have their unique characteristics, such as thin walls, easy deformation, complex curved surfaces, and difficult to process materials. With the continuous advancement of technology, for some 3d printing manufacturers with rich experience and advanced equipment, such as PTJ, complete 3d printing of large aircraft components with high efficiency and low cost is no longer a difficult task.

The Application Of 3D Printing Aerospace Parts

Aerospace has always been one of the important pillar industries in the field of national defense, and a symbol of the strength of a country’s comprehensive scientific and technological strength. As the machining difficulty of aerospace parts such as engine discs, shaft parts, turbine casings, landing gears, etc. continues to increase, various new materials, new structures, and new technologies are emerging in an endless stream, and the requirements for processing technology and craftsmanship continue to increase. And the emergence of 3D printing has made the aerospace industry even more powerful and accelerated the development of the industry.

3d-printing-china.com Aerospace Case Studies

3D Printing Stainless Steel 304 Gear

3d-printing-china.com Supply Stainless Steel 304 Gear Rapid prototyping services, providing design engineering and manufacturing using Solidworks for ...

3D Printing Model Of PA12 Material

The scientific name of PA12 is polylaurolactam, also known as nylon 12. The basic raw material for polymerization is butadiene, which can rely on ...

3D Printing High Temperature Plastic Materials

High Temperature Plastic Materials (Thermoplastics )are plastics that are plastic at a certain temperature, solidify after cooling, and can repeat ...

3D Printing Aluminum 6061 Model

Aluminum alloy, due to its natural lightweight characteristics, occupies an important place in the field of industrial manufacturing. However, with ...

3D Printing Black Photosensitive Resin

Photosensitive resins refer to non-silver photosensitive materials that use certain polymers with photodecomposing properties, or certain monomers ...

PTJ offers online 3D printing services for china rapid prototyping and production of non-metal and metal 3D printed parts at affordable prices.

- * Supports drawing uploads in file formats “.pdf”, “.jpg”, and “.png”.

- * Supports file uploading and loading of 3D (3D) CAD data “.igs” and “.step”.

- * Supports file uploading of two-dimensional (2D) CAD data “.dxf” and “.dwg”.

- PC

- ST-130

- PA 2200

- CoCrMo

- PA 3200 GF

- ABS M30

- Ceramic

- POM-like

- ULTEMTM 9085

- Paraffin Material

- Polyphenylsulfone

- Polyetheretherketone

- Soft Rubber Material

- Aluminum Filled Nylon

- High Ultra-Fine Plastic

- Mold Steel MS1

- NickelAlloy IN718

- Titanium Alloy Ti64

- White Photosensitive Resin

- Black Photosensitive Resin

- Transparent Photosensitive Resin

- Full Color Photosensitive Resin

- Micro-nano Material

- High Ultra-Fine Plastic

- Full-Color Gypsum Composite Material

GET IN TOUCH OR GET A QUOTE

PTJ 3D Printing

Mobile WhatsApp WeChat:

+86 8288 6112

+86 152 1709 1354

Email: [email protected]

Address: Dongguan City, Guangdong Province, China.