The clarinet is a kind of woodwind instrument, usually made of African black wood. It is made of wood, hard rubber or metal. It has a beak-shaped mouthpiece and a circular hollow. The tube body is composed of five detachable tubes. , The tube body is cylindrical, and the lower end is an open bell mouth. Fix a reed at the mouthpiece. When the player blows through the space between the reed and the mouthpiece, and with proper pressure from the lower lip, the thin reed tip vibrates, causing the air column in the instrument tube to vibrate, thus giving out a softness the sound of.

The clarinet mouthpiece is a key part that affects the timbre of the clarinet. Even a small change in the mouthpiece will cause changes in the timbre of the instrument. The ClarinetXpress brand, founded by world-renowned clarinet expert Walter Grabner, provides professional clarinet mouthpieces for clarinet players. ClarinetXpress applied 3D printing technology in the design and development process of the clarinet, and began to try to produce small batches of customized products through 3D printing technology.

Meet the needs of sound quality and customization

For many years, clarinets with ClarinetXpress mouthpieces have been used by musicians to bring people a musical feast in famous concert halls such as the Sydney Opera House and Carnegie Hall.

ClarinetXpress mouthpiece products have always been manufactured by a highly skilled German mechanic. When the mechanic decided to retire, ClarinetXpress was faced with finding another suitable manufacturing method to replace the job of the mechanic.

ClarinetXpress first tried prototype manufacturing through a CNC manufacturer, but due to delivery time and quality reasons, ClarinetXpress decided to try to make mouthpieces through 3D printing technology instead. With the help of a 3D printing service provider, ClarinetXpress optimized the design and manufacturing process of the clarinet mouthpiece.

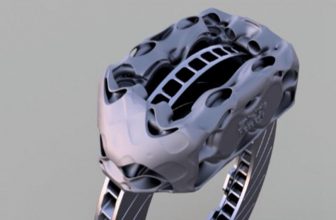

After learning about ClarinetXpress’s product performance and aesthetic requirements, the 3D printing service provider decided to use Carbon’s DLS™ 3D printing technology and rigid polyurethane (RPU 70) to quickly manufacture mouthpiece prototypes, satisfying ClarinetXpress in terms of appearance, texture and sound quality. need. In the first few weeks of the prototype manufacturing process, the service provider team helped Clarinet Xpress to optimize the design of the mouthpiece product. After Clarinet Xpress became familiar with the additive manufacturing process, the design iteration speed was further accelerated.

Clarinet mouthpieces need to meet precise specifications to achieve the quality and pitch required by elite musicians. 3D printing technology can not only meet these requirements, but also compared to ClarinetXpress, which traditionally relies on the personal experience and skills of mechanics, 3D printing this Digital manufacturing technology makes it easier to “copy” high-quality products in batches.

ClarinetXpress often needs to customize a small number of mouthpieces of different types and sizes. Traditional craftsmanship requires the minimum order quantity of the order, but the 3D printing technology is more flexible, able to meet ClarinetXpress’s small batch needs, and can produce many different types of mouthpieces in one printing. It is with the help of 3D printing technology that 3D printing service providers have established a Virtual Warehouse™ for ClarinetXpress to meet ClarinetXpress’s immediate production needs.

In addition, 3D printing technology can directly produce the customized logo elements required by the mouthpiece, without stamping or hand engraving after printing, which further eliminates the cost of managing the production process.

In the 3D printing application case of the clarinet mouthpiece, we can see that this product, which relies heavily on personal traditional skills, is transforming to digital manufacturing. The digital manufacturing technology of 3D printing has unique advantages in flexibly meeting the small batch customization of mouthpieces.

These two points are similar to the hearing aid shell products that have been produced by 3D printing technology instead of traditional manual processes and realized mass customization. Perhaps in the near future, musical instruments such as clarinets will also be fully customized with 3D printing to achieve mass customized production of key components, providing professional musicians with customized and beautiful sound quality.