For China’s manufacturing industry, 2020 will be a year of accelerated transformation.

On the one hand, the downward pressure on the global economy has increased, my country’s exports have decreased, the dividends of low-cost labor have disappeared, and the profits of manufacturing companies have declined [1]; on the other hand, the new crown epidemic has made the global economy worse, and market demand has fallen. The global supply chain includes Chinese manufacturing. The industry faces huge challenges.

On the other hand, the epidemic is also an opportunity, forcing us to reflect on how the manufacturing industry can avoid systemic risks and strengthen agility and resilience on the basis of ensuring the stability and flexibility of the supply chain in today’s tightly bundled and coordinated global supply chain. Responding to the “black swan” and “gray rhino” incidents; and how to seek opportunities in crisis under the new normal of the post-epidemic economy, deploy endogenous growth power, and increase the added value of the industry.

Accelerate the digital transformation of the manufacturing industry

Since 2015, the State Council and various ministries and commissions have successively issued a series of policies, laws and regulations to support the development of the Industrial Internet and smart manufacturing, promoting the wide application of new technologies such as 3D printing, big data, and artificial intelligence in the manufacturing field, and fostering new smart manufacturing models , To promote the transformation and upgrading of production methods to flexibility, intelligence, and refinement.

However, before the outbreak of the epidemic, manufacturing companies generally did not have a deep understanding of the urgency of digital transformation of production, and their understanding was too simple. Among them, the advantages of 3D printing have not been fully explored, and its main role is still how to adapt, cooperate, and supplement the traditional manufacturing centralized production and unified assembly process.

“Tradition” still dominates, and there is still no substantial breakthrough in costs and benefits.

After the outbreak, many countries and regions around the world experienced severe shortages of medical and protective materials, and the supply chains of countries around the world were also severely affected, ranging from electronic equipment, vehicle and component manufacturers to consumer goods and other industries. After the epidemic, global manufacturing companies including China began to re-examine the process of digital transformation and supply chain innovation, hoping to build a flexible + resilient supply chain with the help of digital intelligent technology.

On the bright side, in April this year, the National Development and Reform Commission clearly put forward “new infrastructure” as a new key investment development direction for the first time, and jointly issued implementation rules with other ministries and commissions. This has laid a policy foundation for the rapid transformation of traditional Chinese manufacturing to intelligence and digitalization and the in-depth application of 3D printing technology.

3D printing smart solution

The digital manufacturing technology represented by 3D printing is regarded as one of the core technologies leading a new round of technological revolution and industrial transformation. It is an important part of the fourth industrial revolution and has broad development and application prospects. 3D printing and traditional manufacturing are not a substitute relationship, but should give play to their advantages in their respective areas of expertise.

In the past, manufacturing companies that used traditional production methods had the following characteristics. For example, the initial investment was large, and sales were determined by production. They were unable to make timely adjustments based on market feedback, and it was difficult to achieve customized production for different consumer needs; the production process was cumbersome. , And it is a centralized production, which leads to the rapid transmission of systemic risks in the entire supply chain once the systemic risks come. In addition, traditional production methods also face environmental protection and sustainable development issues. 3D printing can well make up for these shortcomings of traditional manufacturing, and promote the transformation of manufacturing enterprises from traditional production methods to intelligent manufacturing.

With the increase in national income and consumption levels, consumers’ demand for personalized and customized products is increasing year by year. Based on digital models, 3D printing can design and customize products according to the needs of different consumers. It can not only realize flexible production and promote manufacturing enterprises from traditional mass production to mass customization, but also greatly shorten the product improvement cycle and reduce optimization costs. After all, it is much simpler to modify the electronic drawing than to reopen the mold or even modify the entire production line.

At the same time, 3D printing can also greatly streamline the supply chain and production process. Let us imagine: in the near future, both consumers and enterprises will be able to make or modify product designs through various smart terminal devices. After the proposal is submitted, the brains located in the cloud will interact with large and small 3D printing platforms and even across the country. Separate equipment connection, the two parties complete automated quotation, price comparison, and evaluation in a very short time, and then enter the subcontracting and modular production link. This distributed supply chain reduces warehousing and logistics costs, brings production closer to the end market, and enhances the resilience of the supply chain.

Data-oriented, application is king, scale wins

If manufacturing companies want to improve efficiency from the current use of digital means to comprehensive digitalization from design, optimization, production to post-processing, they need to closely integrate 3D printing technology with the industrial Internet. The digital arterial road laid by the new infrastructure brings convenience to this goal. In addition, HP maintains long-term strategic cooperation with leading domestic and foreign industrial software partners such as Siemens, which can support manufacturing companies in real-time remote monitoring of production and historical data analysis to track, manage and optimize production operations, and make production processes more intelligent.

In the process of moving toward a broader market, we believe that 3D printing needs to closely follow the word “application”-truly cut into the core link of the manufacturing industry, and cooperate with upstream and downstream to solve the problem of the all-digital process from design to manufacturing. Achieve a comprehensive upgrade of the industrial chain. BMW is already applying the new HP Jet Fusion 5200 series 3D printing solutions and is constantly exploring new application scenarios. Smile Direct Club is an orthodontic service provider. Since the introduction of HP Multi Jet Fusion (MJF) 3D printing technology, it has been able to produce more than 50,000 unique dental molds every day, and will achieve 20 million customized dental molds within one year. Target.

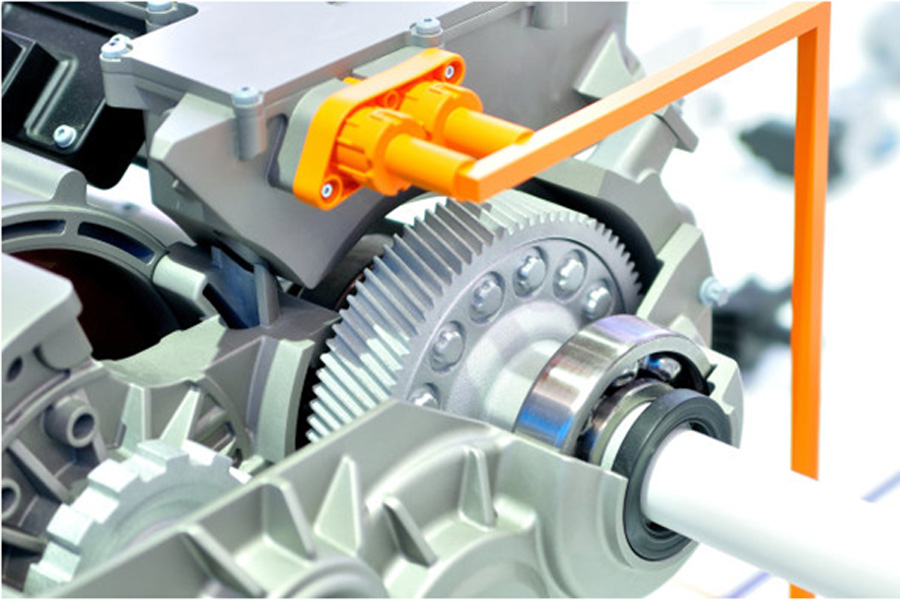

At present, HP is actively exploring new materials, using new materials to promote new applications and open up new prospects. For example, in the automotive industry, HP is working with Volkswagen to use metal 3D printing technology for mass customization and manufacturing of decorative parts, and plans to integrate metal 3D printed structural parts into next-generation vehicles as soon as possible.

Driven by the diversity of materials, 3D printing technology will enter various industries to realize the possibility of large-scale applications. Just last September, with the support of HP’s industrial-grade HP Jet Fusion 5200 3D printing equipment, the German engineering company EDAG and Siemens Digital Industries cooperated to develop a 3D printing active coolant distributor, which was installed in the “EDAG SCALEbat” for the first time. In the battery case. The large-scale production concept of up to 300,000 pieces proves the economic feasibility of manufacturing parts through 3D printing in mass production.

In addition, with the assistance of BASF, HP will provide the first polypropylene (PP) material for 3D printing to the Chinese market this month. It is a multifunctional, durable, and chemical-resistant material. It has been certified by HP’s industrial-grade 3D printing system. It is ideal for companies in fields such as automotive, consumer, industrial and medical. It can be used for large-scale production with high cost-effectiveness. choose.