Modellbau Clauß was founded in 1948 and is located in Neukirchen near Chemnitz, Germany. It initially produced casting molds, using wood at first, then using plastic, and then using metal when the first batch of CNC machine tools were born. Today, their products also include molds and prototypes. Modellbau Clauß is a family-owned company with 45 employees and customers from the automotive, machinery manufacturing and complete equipment sectors. Since 2003, Modellbau Clauß has been using turning centers and milling centers from DMG MORI. After 2018, it invested in DMG MORI’s second-generation LASERTEC 30 SLM 3D printer to use it for additive manufacturing of metal workpieces.

Ulli Clauß said, “In terms of producing models and prototypes, the continuous development of 3D printing technology has benefited us a lot.” Ulli Clauß and Rico Clauß brothers are the third-generation managers of the company and will use additive manufacturing technology. Used in their production. Rico Clauß added: “After purchasing the first plastic mold 3D printer, we quickly realized the potential of additive manufacturing for the production of metal prototypes.”

The new potential of powder bed additive manufacturing technology and the new geometry of the workpiece

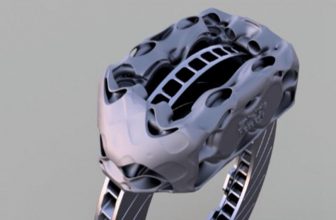

Modellbau Clauß has used five DMG MORI machine tools, and now it has added DMG MORI’s 3D printing technology. Ulli Clauß said: “The second-generation LASERTEC 30 SLM is an ideal complement to our existing machine tools.” This powder bed additive manufacturing machine has a forming area of 300 × 300 × 300 mm and can be used to produce very complex shapes and hollows. The material of the workpiece, such as aluminum or steel. “This kind of geometric modeling cannot be achieved with subtractive technology.” Combining 3D printing and DMG MORI’s 5-axis machining technology can perform finishing on metal workpieces produced by additive manufacturing. It was impossible to imagine such a workpiece before.

Rico and Ulli Clauß saw the great value of using powder bed selective laser fusion technology to produce complex geometries: “This technology can meet the requirements of extremely complex workpieces and open up new businesses. For example, the technology is now used to produce carbon fiber rim molds. “Now, we use the second-generation LASERTEC 30 SLM to meet the manufacturing requirements of conformal cooling channels. “

rePLUG safely changes powder within 2 hours

The second-generation LASERTEC 30 SLM purchased by Modellbau Clauß is equipped with three rePLUG powder modules. Ulli Clauß explained: “Therefore, we can use different metal powders at any time.” Within two hours, the machine operator can complete the replacement of each powder module, completely avoiding pollution. Rico Clauß discovered the advantages of a closed powder cycle: “Closed means completely safe handling of powder.”

Write part program offline and transfer the program to CELOS APP application RDesigner. CAM programming with CAD data in a user-friendly environment.

Innovative and full-featured CELOS software solution

The second generation LASERTEC 30 SLM is equipped with DMG MORI’s unique control system and user interface CELOS. For workpieces with very complex geometry, perform offline programming, and transfer the program to the machine tool after programming. Ulli Clauß introduced the situation of the machine tool in daily use. He said: “This is a completely open system. That is, all the settings and parameters of the machine can be adjusted individually.” In the CELOS APP application, RDesigner is based on the CAD model. CAM programming software. It can also be used for heating calculations. Before forming, use it to calculate the mass distribution and automatically adjust the laser parameters. CELOS’s “Task Management” APP application provides all parameters related to machine tools and tasks, including camera-based testing and the function of detecting errors at each workpiece level.

Leveraging on proprietary technologies in the field of additive manufacturing to launch new businesses

Modellbau Clauß’s accumulated experience in the field of 3D printing, especially powder bed process experience and upstream and downstream technical capabilities, such as design and post-processing, lay a solid foundation for the company’s future development. Additive manufacturing technology has not yet been applied to all development links, Ulli Clauß said: “We want to let customers understand the potential of additive manufacturing technology to provide design freedom and optimize workpieces.”