Researchers at Harvard University’s School of Engineering and Applied Sciences (SEAS) have developed a 3D printing material that can be pre-programmed to have a reversible shape memory function. The Harvard team’s new filament consists of two keratin chains arranged in a twisted spring-like structure. Once combined into a “coil”, the material can be changed to any shape, and then restored to its original shape with the “shape memory effect”.

Considering that the team’s biocompatible material is made of recycled wool, the polymer also has potential ecological benefits and has been applied in the fields of medical repair and textiles. Kit Parker, the senior author of the paper, said: “Through this project, we have proved that we can not only recycle wool, but also make things from recycled wool that we have never imagined. With regenerated keratin, what we can do It can do as much or more as shearing, and reduce the environmental impact of the textile and fashion industries.”

Growing demand for shape memory materials

In recent years, the number of applications of shape memory materials has increased exponentially. Companies in the fields of civil engineering, aerospace, wearables, and medical devices have all shown a growing demand for customizable polymers and greater flexibility than existing polymers. Despite recent research in this field, the development of customizable and biocompatible materials remains a challenge. In particular, it has been proved that it is difficult to control the actuation mechanism of polymers at the molecular level on all spatial scales.

Shape memory features are usually associated with composites, but they can also be seen in biological matrices, and keratin-based spirals indicate continuous structural transformations. In biological tissues such as sea snail oocysts or animal skin, they evolved this mechanical transformation to protect them from predators. Inspired by applications in nature, the Harvard team set out to replicate the response in highly processable printed materials.

The researchers’ new filament is based in particular on the anisotropic keratin tissue present in animal hair. Using natural wool as the basis of the team’s 3D printing material has many advantages, such as water-triggered response and higher tensile strength than similar existing systems. Production based on extrusion has also proven to be highly compatible with wool because it can self-organize into “fibrils” (or clusters), thereby improving processability.

Harvard team’s wool filament

The research team used fibrillary keratin extracted from Angola wool from discarded clothing to create a new 3D printing polymer. In order to extract and utilize the keratin content in wool, the research team used a combination of lithium bromide and dithiothreitol (DTT) solutions to induce a solid-liquid transition. The resulting crystallized keratin is then further extruded to transform it from a protein concentrate into a printable hydrogel.

To assess the impact of chemical reactions, the research team deployed low-temperature transmission electron microscopy to verify that individual keratin chains have successfully formed coiled coils. The results showed that the single strands had aggregated into larger fibrils, about 3 nm, with almost no signs of protein degradation. Further photomicrograph testing also showed that the tensile strength of the material was +1.03MPa, which is the same as the tensile strength of nylon and silk fibers.

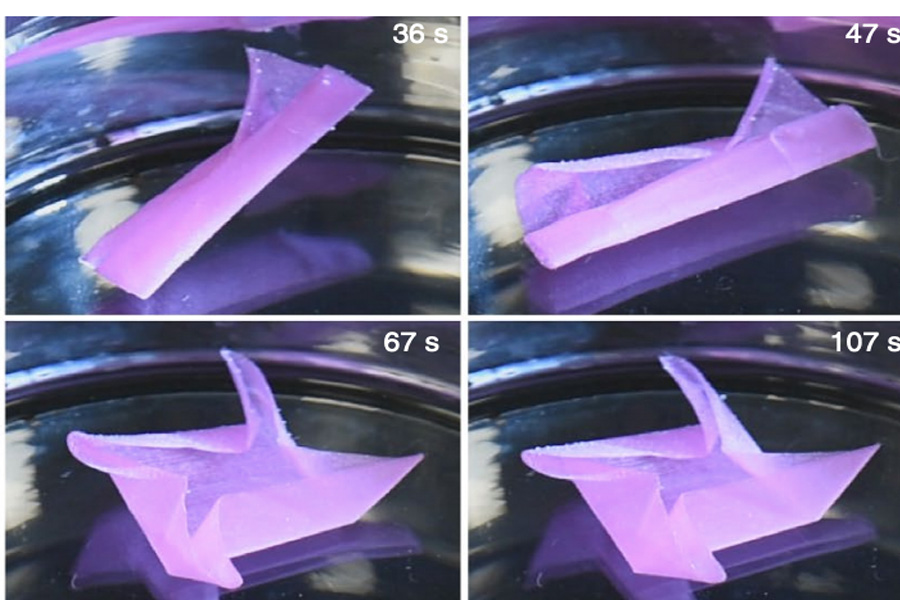

Crucially, it was also found that fibrils would self-organize into nematic phases when subjected to shear stress, and would return to their original shape under pre-programmed stimulation. In order to evaluate the shape memory potential of its new material, the Harvard team 3D printed keratin sheets into various shapes and structures. Then a mixture of hydrogen peroxide and sodium dihydrogen phosphate was used to make the shape permanent, and then the prototype was immersed in water. Once underwater, these materials become malleable and can be reshaped into any desired layout, but when they are removed, the dried fibers return to their pre-programmed shape.

As the fibers dry and their hydrogen bonds begin to reform, these sheets show a sudden increase in stress, which corresponds to the return of the material to the same level of tensile strength as before. After rehydration, after several cycles of stress and strain, the recovery efficiency of the fiber reached a value close to 100%, and the observable shrinkage rate was the smallest.

Comment: They created a unique fiber-based 3D printing material based on a hierarchical structure, which has shape memory properties and high mechanical stability. The Harvard University research team believes that their renewable resources may be used in the future to produce biodegradable smart textiles, such as clothing that can absorb human functions or medical products that absorb strain energy. Parker concluded: “Whether you are using this fiber to make a bra with customizable cup sizes and shapes every day, or trying to make actuated textiles for medical use, the possibilities for our work are vast and exciting. We are Continue to reimagine textiles by using biomolecules as engineering substrates, just like they have never been used before.”

Shape memory polymer previously developed

Given the increasing end uses of shape memory materials, it is not surprising that many other researchers have developed their own polymer-based alternatives. Scientists at ETH Zurich have developed a series of supernormal materials with 3D printing shape memory function. The material is part of a broader research project for active deployment of structures and can potentially be used in biomedical, aerospace, or engineering equipment.

The research team at Lawrence Livermore National Laboratory (LLNL) has used Direct Ink Writing (DIW) 3D printing technology to create silicone structures that can recover from compression. Silicone may have future applications in “wearable protective pads”, which can be activated under certain temperature conditions.

Researchers at the Georgia Institute of Technology have used additive manufacturing to create stretchable objects that can change shape according to the level of tension applied to them. The material can be programmed to expand dramatically, making it possible to use it in future biomedical or aerospace products.