Additive manufacturing, commonly known as 3D printing, is a new manufacturing process that emerged at the end of the last century. Due to various restrictions, it has not been widely used in the industry. Under the technical conditions and application environment of the new industrial era, this technology has been re-emphasized by the industry and has been rapidly applied.

In “You use simulation as a vase, we use it to change the world”, Tian Feng, senior vice president of Nexperia Asia Pacific, mentioned that the redesign was possible because of the emergence of new technologies and new processes, among which are representative new processes. It is additive manufacturing. Do not regard additive manufacturing as purely a manufacturing technology, and oppose the use of additive manufacturing technology to print a traditional product. Additive manufacturing can realize designs that cannot be manufactured by traditional craftsmanship, and gives unlimited freedom to forward design. Product design only needs to be based on requirements and functions, without considering manufacturing constraints and subversive innovation. For the unlimited innovation space provided by additive manufacturing, the design itself has no specifications and standards, so simulation has become the most important tool. Therefore, redesign is the first in-depth application of simulation technology.

While looking forward to the unlimited development space brought by additive manufacturing, in fact, the metal additive process is also facing huge challenges. Without simulation, metal additive manufacturing will encounter serious bottlenecks and can only be sealed in the low-level application space. This article will face the additive process simulation-the second in-depth application of simulation technology.

Challenges facing metal additive manufacturing

Although the growth rate of metal additive manufacturing has been very impressive in recent years, whether it is direct energy deposition process or powder bed melting process, there are several types of challenges:

The types of metal materials that can be printed are limited, and there is an urgent need to develop more metal types to meet industrial needs;

Restricted by printing speed and efficiency, it is not suitable for mass production;

The printing cost is too high, including machine cost, powder cost and additional cost caused by higher printing failure rate;

Need tedious and lengthy post-printing processing links;

It is very difficult to ensure the quality of printed parts and process debugging.

Among them, quality assurance is a crucial factor in obtaining qualified prints. Metal additive manufacturing may have problems such as component deformation and cracking. The same component, under the same processing parameters, layer number, and material conditions, uses different orientations and positions, and the microstructure and properties of the finished product are different. For example, the residual stress level of columnar crystals in the vertical direction is low, and the residual stress in the martensite phase in the horizontal direction High level.

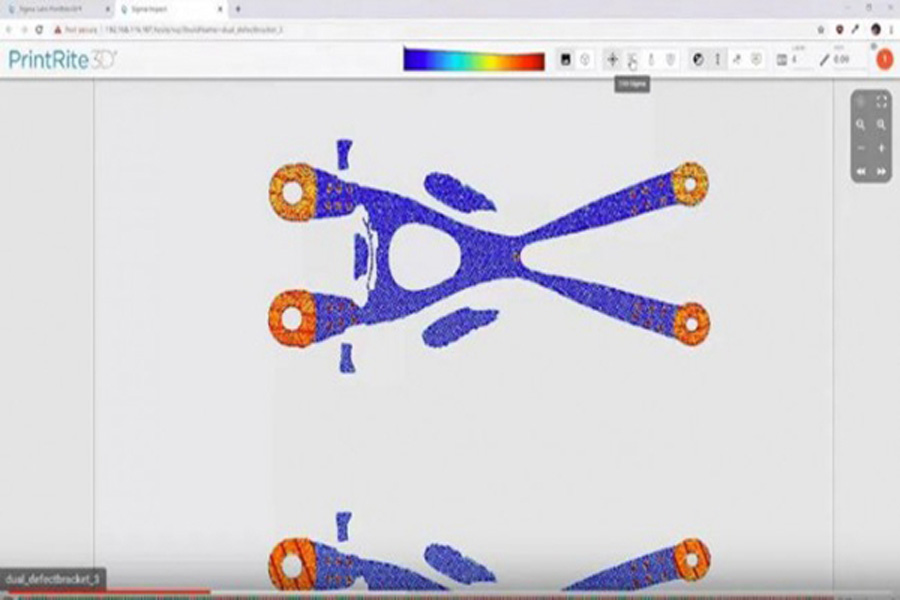

The additive manufacturing process simulation mainly studies the effects of processing parameters, powders, geometric configurations and other factors on macroscopic deformation, residual stress, microscopic internal metallographic structure and performance of components. Macro-control and micro-control are two important inspection indicators in metal additive technology: Macro-control focuses on warping deformation, component cracking, scraper collision or support cracking; micro-control needs to pay attention to porosity and phase change , Spheroidization, particle size, primary and secondary dendrite structure and initial dislocation density and other microscopic properties, which will determine the mechanical properties and characteristics of metal parts.

Metal additive manufacturing may seem simple, but the real process is very complicated. Whether a qualified part can be successfully printed is affected by many factors such as materials, printer equipment, process design, process parameters and settings, and post-processing. For an actual metal print, the success rate of printing is low based solely on experience or intuitive feeling. The trial and error method not only increases the cost, but also prolongs the product manufacturing cycle.

The significance of metal additive process simulation

Using simulation technology to obtain the performance characteristics of printed products in advance is an important means and method to solve the problem of metal additive process quality. By predicting in advance and optimizing the process on this basis, the probability of printing failure can be reduced, and the printing cost can be reduced to a large extent, and the number of unqualified products and the number of trial and error can also be greatly reduced.

Although additive printing technology has the characteristic of “manufacturing no matter how complex it is,” the printability of products with the same function can be greatly enhanced with slightly different designs. This has a significant impact on the printing success rate and manufacturing compensation, which may increase the utilization rate of the machine, shorten the product printing cycle, and ensure the repeatability and quality of product printing. If the microstructure and properties prediction can also be realized through simulation, it will greatly speed up the development of new materials, new machines, and new process parameter packages, reduce research and development costs and cycles, and obtain personalized microstructures and control material properties will become possible. The value of simulation for metal additive printing is summarized as shown in the figure below.

Difficulties in metal additive process simulation

Although the value of additive process simulation is huge, it is equally difficult to implement. The main difficulties include the following aspects:

I. The scale of spatial discretization is huge, the number of time discretization steps is huge, and the calculation time is long

The spot size is small, the macro size is huge, and the size contrast between them makes the grid discrete scale huge. At the same time, the printing time of printed parts is generally relatively long, small parts are calculated in hours, and large parts are calculated in days, while the time step of thermal-solid coupling simulation needs to be discrete on the order of microseconds or even less. With existing computing hardware resources, it is very difficult to simulate the printing process.

2.Multi-scale problems with the coexistence of macro, micro and mesoscopic

Whether it is a physical phenomenon or the scale of the research object, the dynamic study of the non-equilibrium state of rapid cooling and solidification inside the molten pool needs to be carried out by the microscopic theory of materials. How to introduce mesoscopic to unify the microscopic phenomenon and the macroscopic phenomenon requires analysis from a multi-scale perspective.

3.The mechanism of the physical process is complex

Only considering the physical phenomena in the molten pool, additive metal printing is already very complex, including physical processes such as infiltration, capillarity, surface tension, Marangoni convection, molten pool dynamics, and phase transitions. The exact mechanism and evolution law of its physical changes need to be verified and summarized by experiments in engineering, and it is difficult to completely predict and summarize it using only physical control equations.

4.Many factors and links are involved

The quality of additive metal manufacturing is not only related to the quality and characteristics of the metal powder, but also to the printability of additive design, machinery and equipment, printing process, printing parameter package and post-processing.

5.Many sources of uncertainty and error

Due to the long link and many factors involved, there are also many sources of uncertainty and error.

Simulation of a typical metal additive process (SLM)

In addition to SLM, EBM, SLS and DMD, the metal additive process also has derivative process methods such as LBW, EBW, RPD, etc. Here we take the more popular and commonly used SLM (Powder Bed Melting Process) as an example to introduce the simulation of the metal additive process.

SLM metal additive manufacturing process simulation is a very complex typical multi-scale and multi-physics analysis process. Multi-scale is embodied in the scale span from macro to mesoscopic to micro. Multi-physical field needs to control the molding temperature field, gas field (protective gas), melt flow field (melt pool fluid), and velocity field (powder spreading process). And the solid stress and deformation field of the printed structure are analyzed, which can be applied to every stage of metal additive manufacturing.

6.Macro-scale process simulation

The macro-scale simulation analysis is mainly aimed at the process simulation of part forming, and predicts the stress and strain during the forming process, the forming temperature field and the possible risks in the forming process. The object of macro analysis is the supporting object of the print itself and process design, and it may also include the substrate and necessary machine equipment information such as laser light source. According to different process simulation algorithms, there are currently two main methods used in macro-scale metal additive manufacturing process simulation, namely, temperature and structure coupling (thermo-elastoplastic) finite element analysis method and inherent strain finite element analysis method. The simulation analysis results of the macro-scale process usually include: deformation and residual stress of components and supports (before/after support removal), layer-by-layer stress and deformation, deformation compensation, scraper collision detection, high-strain area, and stress-based optimization Support etc.

7.Mesoscopic molten pool and powder analysis

Meso-scale simulation analysis is mainly for the analysis of molten pool and powder, including molten pool fluidity, molten pool size and morphology, powder fluidity, powder heat transfer, evaporation and splashing after melting, etc. The molten pool needs to be considered The internal surface tension, capillary, infiltration and Marangoni convection phenomena are currently mainly used in this analysis by equivalent thermal coupling and CFD methods. Predict the melting process and solidification process through molten pool dynamics, and obtain the phase transition history, temperature history, temperature gradient history, and solidification cooling rate.

At present, there are two main methods used in the simulation of mesoscopic metal additive manufacturing processes, namely, the method that does not consider the powder scale inside the molten pool and the method that considers the influence of the powder. Meso-scale simulation analysis simulates the flow and heat transfer inside a smaller-scale molten pool. In addition to predicting temperature, temperature gradient and cooling rate, it can also predict surface quality, interlayer viscous force, porosity, etc. Meso-scale simulation analysis is generally a single-channel scanning object, and multi-channel scanning is rarely performed, but the conclusions and results obtained can modify the macro-simulation results, and can also be connected as the input of subsequent micro-scale analysis.

8.Micro-scale organization simulation

Using the temperature gradient or solidification cooling rate obtained from the macroscopic or mesoscopic scale analysis, the microscopic scale simulation can be used to predict the crystal structure morphology, grain size and orientation, defects and performance of the product. The important methods currently used mainly include phase field method (Phase Field), automatic cell machine (Cellaur Automaton), etc. Different methods have their own characteristics and limitations.

The microstructure obtained in the metal additive manufacturing process will directly affect the performance of the molded part. Obtaining a crystal structure with high density and good grain orientation and size is an important goal of metal additive manufacturing. Affected by the complex process of metal additive manufacturing, the simulation analysis of crystals is also quite difficult.

After the temperature field or phase change result data obtained by macroscopic analysis or mesoscopic analysis, the thermal gradient, solidification rate, cooling rate and morphological factor can be further calculated, which are the input parameters for micro-scale metallographic simulation.

Numerical simulation of microstructure usually includes deterministic method, probability method and phase field method. The deterministic method usually has the leading edge tracking method, and the probability law includes Monte Carlo method and CA method. Both the determination method and the probabilistic method need to track the solid-liquid interface when simulating grain growth to simulate the morphology of the dendrites, but it is difficult to simulate the three-dimensional morphology. The phase field method is based on Ginzburg-Landau theory, and uses differential equations to embody the combined effects of diffusion, ordering potential, and thermodynamic drive. With unified control equations, it is not necessary to distinguish between solid and liquid phases and their interfaces, and can be directly simulated The formation of microstructure. Phase field method and cellular automata method are two commonly used numerical simulation methods for microstructure simulation.

The relationship between the macroscopic, mesoscopic and microscopic simulation analysis of the metal SLM additive process

9.Other focus on additive process simulation

At present, the applications of additive process simulation that pay more attention to include the following topics, and the details are not repeated here:

Special post-treatment (such as hot isostatic pressing), analysis of the effect of heat treatment on macroscopic deformation and elimination of residual stress, microscopic simulation (such as density enhancement and metallographic improvement simulation), subsequent machining process simulation, flow inner surface smoothing simulation Wait;

Support processing and equivalent simulation in the macro simulation, including volume support, Cone support and Block surface support, subsequent richer support will also be considered in the macro process simulation;

Microscopic metallographic structure simulation, which will directly support the prediction and evaluation of material mechanical properties.

Trends and development directions of additive process simulation

With the support of simulation technology, additive manufacturing will break through the bottleneck, give full play to its advantages, and realize the huge innovation space people expect. But with the development of additive manufacturing technology, additive process simulation technology will also continue to improve. We believe that its future development trends are mainly in the following directions:

Macro-scale additive process simulation will become more popular and applied in engineering. Additive process simulation will be gradually introduced in the full cycle of additive design, process and manufacturing to ensure the printability of designed products;

Materials-equipment-printed parts-support design and process design-process parameter package-macro characteristics-micro characteristics-post-processing-performance prediction, the entire process will be streamlined and platformized;

Mesoscopic analysis and microanalysis will gradually move from the research and scientific research stage to the engineering application;

Support design and optimization software driven by physical process simulation will be gradually available;

Using test data and simulation data, AI algorithms and multi-scale algorithms will realize offline prediction of additive processes;

More metal material data will be tested and entered, and more metal additive process methods will be simulated.