Guide

- How to Calculate 3D Printing Price (SLS, SLA, SLM, MJF, FDM, ETC.,)

- Anodizing vs. Painting: An In-depth Analysis

- 9 Types of 3D Printed Metal Copper Techniques

- 3D Printing Materials and How to Choose the Right One?

- What Is Micro Manufacturing Technology

- Wire 3D Printing: Process, Filament, Printer and Features

- Uncover The Mystery Of CNC Machining

- Huazhong University of Science and Technology has made new breakthroughs in ultrafast laser 3D printing of fine and complex semiconductor micro-nano structures

- In 2025, there will be more than 600 metal 3D printing equipment serving China’s aerospace and other fields

- Looking at the development trend of 3D printing from Formnext 2021

- 3D printed prototype silica gel molds, realizing small batch production of industrial products

- Global architectural 3D printing inventory, no need to move bricks to build a house

- The latest application cases of 3D printing in aviation

- 3D printing everything? Japanese media: Printable buildings, parts, organs and even food…

- 3D printing provides emergency production of anti-epidemic products, global anti-epidemic

Case Studies

Accelerate The Development And Innovation Of The Artificial Intelligence Field

Inject new kinetic energy into artificial intelligence, broaden innovation horizons, and enhance industrial value

3D Printing Technology For Artificial Intelligence

From Alphago’s defeat of Li Shishi to self-reproduction of 3D printing, we seem to have no doubt that artificial intelligence + 3D printing will bring endless possibilities. According to the exponential acceleration of Moore’s Law, the future will be more than ten or twenty. More earth-shaking changes will take place this year.As the two most representative key technologies of the fourth industrial revolution, both artificial intelligence and 3D printing have made significant progress. The organic combination of the two has spawned many emerging needs, and at the same time promoted the optimized development of their own industries. . Artificial intelligence was born in response to big data, providing big data with a deep thinking brain, while 3D printing gave intelligent digitalization a strong body, and finally jointly triggered the arrival of the intelligent era. With the advent of the era of intelligent manufacturing, we believe that 3D printing and artificial intelligence will achieve more unexpected results in the future.

Table of Contents

Why Choose Our 3D Printing Artificial Intelligence Service?

PTJ meets or exceeds the quality standards of the world’s most demanding industries with our state of the art equipment and quality standards. Our precision and productivity is made possible by our ultimate success factor: the presence of skillful, knowledgeable PTJ experts in Artificial Intelligence 3d printing and more additive manufacturing parts.

- No minimum order quantity

- Metal or plastic 3D printed prototype and production parts in 7-10 days

- Precision custom 3D printing parts at affordable prices

- Online free quote in the shortest time

- Single prototypes or complex shapes are both allowed

- A wide selection of metal or plastic materials

- Commercial and industrial-grade 3D printers

- Cooperative supplier assistance project

- Provide a quick solution for small batches of complex prototypes

- Provide a quick solution for small batches of complex prototypes

- We provide with our partner

- 3D printing services for metals and plastics

- Meet the rapid needs of complex prototype designers

In The Field Of Artificial Intelligence, What Needs Does PTJ Solve For Customers?

A McKinsey report predicts that by 2025, more companies will adopt 3D printing technology and shift their focus to product personalization. Over time, the sources of competitive advantage in the value chain will change, and design and consumer networks will become the core. In this case, economies such as China that rely on low-cost mass production will be at a disadvantage in the competition.

With the steady advancement of the “Made in China 2025” plan, “Intelligent Manufacturing in China” will rise strongly. With the rapid development of intelligent manufacturing, 3D printing can effectively interact with many advanced technologies such as big data, cloud computing, robots, and smart materials. The combination of technology and the integration of “materials-design-manufacturing” will surely become a key link in the high-end equipment manufacturing industry in the future. It will revolutionize manufacturing methods and industries, as well as productivity and production relations. China’s manufacturing industry is expected to rely on 3D printing Technology takes the lead in high-end manufacturing.

3D Printing AI Process

Interactive Design

Based on accurate and personalized data collection, our technical team will put forward reasonable suggestions for customers’ product design, and use our rich experience in the field of intelligent hardware to provide customers with optimized and achievable solutions.

Test Verification

Through 3D printing, we provide customers with high-efficiency and low-cost test samples, quickly verify design schemes, reduce trial and error costs, and promote continuous iterative upgrades in research and development.

Small-Scale Mass Production

No need to open the mold, shorten the production cycle, reduce production costs, and speed up the time for products to be put on the market.

Personalized Flexible Manufacturing

The personalized demand of artificial intelligence products is increasing day by day. These intelligent products require accurate three-dimensional data to support, and tailor-made flexible production methods will become a necessary condition for intelligent hardware to meet customer needs.

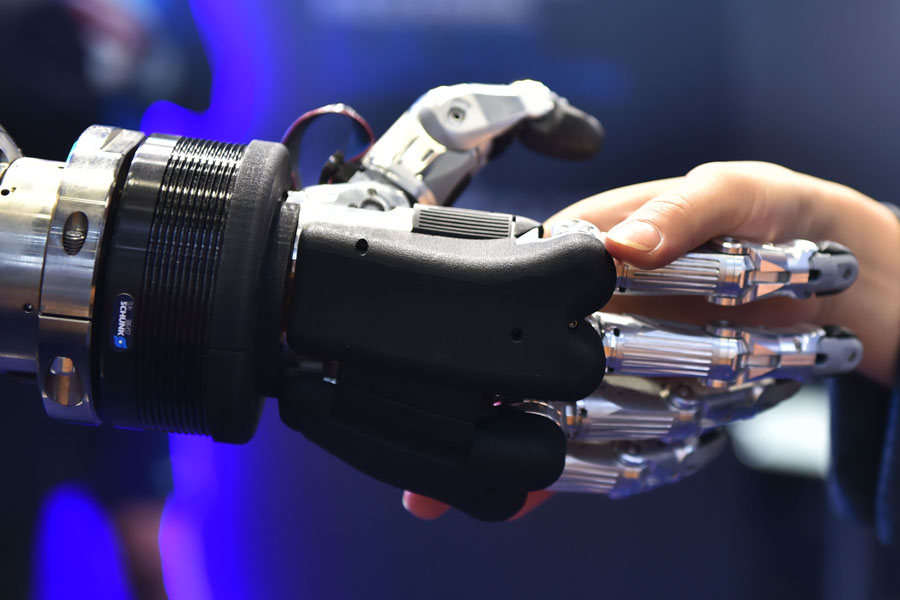

3D Printing And Robotics

The emergence of 3D printing and artificial intelligence has revolutionized the robot manufacturing industry. For the first time, robot manufacturing has become more like the evolutionary process of humans or organisms.

In the past robot manufacturing, engineers always designed each part of the robot according to the existing theory and the set goals that need to be achieved, and finally assembled the robot to test the performance of the robot. Now, robot manufacturing is more like a process of intelligent evolution controlled by the creator. In the computer-simulated virtual space, engineers can set goals that a robot needs to achieve, such as travel speed, travel mileage, or walking under specific terrain. Then the computer will perform virtual 3D printing based on the originals that can be used.

These virtual 3D printed robots are completely random, and they look weird and even look like coelenterates and worms in nature. The computer will try to place the control element and the drive element in different positions of the robot. Then let these robots compete in the virtual space, leaving those with superior performance in the same group and deleting those with poor performance. Then find common points among virtual robots with superior performance to create robots that can better meet the original needs.

This change is not only as simple as the combination of 3D printing and intelligent design, but its significance is that for the first time, humans have given the ability to design, control and evolve to machinery, turning robots into a mimic that can multiply.

AI Enables 3D Printing To Realize Machine-Made Machines

If the engineering technology is advanced enough, we can completely imagine such a mechanical creature: its main structure is composed of two parts: the input end and the output end, and a self-printing 3D printer is placed inside. When it starts, the sensor will Automatically find the surrounding materials for 3D printing and “eat” this material into the body. When there is enough material, the internal 3D printing device will start to “give” a new self, and this self is in It is an improved product after millions of simulations have been carried out on the computer inside the robot. This new mechanical creature will have the ability to metabolize, respond to stress and reproduce. Although its appearance may not look like a creature at all, it satisfies most of the characteristics of the human definition of life.

3D printing And Artificial Intelligence

On the one hand, 3D printing modeling programs increasingly include artificial intelligence factors to help people create the best 3D printing models. Artificial intelligence can also help improve the 3D printing technology itself and make the printing process more and more efficient; on the other hand, On the one hand, 3D printing can accelerate the innovative development of artificial intelligence products and better achieve the goals of artificial intelligence.

The main application directions of 3D printing in artificial intelligence:

- ■Intelligent robot development;

- ■Checking tools and fixtures of intelligent production line;

- ■Preoperative model of telemedicine;

- ■Direct printing of core circuit, etc.

Digital Manufacturing Factory Of The Future

As two important components of digital unmanned factories, artificial intelligence and 3D printing have been scientifically verified in the advanced manufacturing system and have unlimited imagination. In the future, an artificial intelligence brain with functions such as automatic identification of materials and process methods and scientific optimization of error correction will direct 3D printers that meet the needs to mass produce personalized products in real time.

This will be the grand blueprint for the future factory of digital manufacturing.

PTJ offers online 3D printing services for china rapid prototyping and production of non-metal and metal 3D printed parts at affordable prices.

- * Supports drawing uploads in file formats “.pdf”, “.jpg”, and “.png”.

- * Supports file uploading and loading of 3D (3D) CAD data “.igs” and “.step”.

- * Supports file uploading of two-dimensional (2D) CAD data “.dxf” and “.dwg”.

- PC

- ST-130

- PA 2200

- CoCrMo

- PA 3200 GF

- ABS M30

- Ceramic

- POM-like

- ULTEMTM 9085

- Paraffin Material

- Polyphenylsulfone

- Polyetheretherketone

- Soft Rubber Material

- Aluminum Filled Nylon

- High Ultra-Fine Plastic

- Mold Steel MS1

- NickelAlloy IN718

- Titanium Alloy Ti64

- White Photosensitive Resin

- Black Photosensitive Resin

- Transparent Photosensitive Resin

- Full Color Photosensitive Resin

- Micro-nano Material

- High Ultra-Fine Plastic

- Full-Color Gypsum Composite Material

GET IN TOUCH OR GET A QUOTE

PTJ 3D Printing

Mobile WhatsApp WeChat:

+86 8288 6112

+86 152 1709 1354

Email: [email protected]

Address: Dongguan City, Guangdong Province, China.