Australian metal additive manufacturing service provider Amaero has signed an agreement with an unknown car manufacturer to jointly develop 3D printing tools. Specifically, Amaero will use its metal additive manufacturing technology suite to manufacture steel inserts for two aluminum casting mold components. According to Amaero, the use of additively manufactured cutter blades can reduce the risk of manufacturing defects by adding conformal cooling channels to the design.

Amaero CEO Barrie Finnin said: “This agreement strengthens Amaero’s growth strategy in the most difficult economic environment. We can use complex internal cooling channels to print tool steel blades, which are currently not possible with traditional technology. of.”

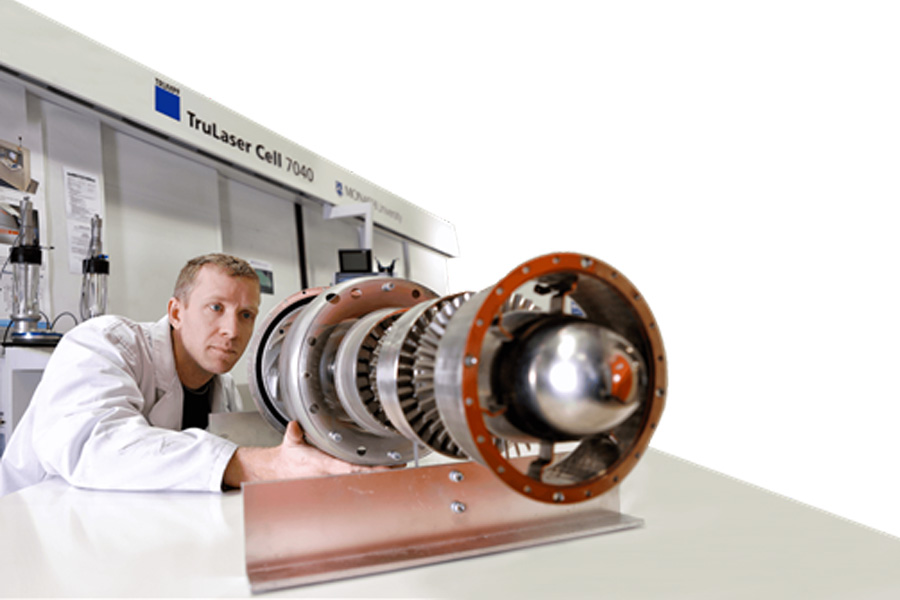

Monash University

Founded in 2013, Amaero is a branch of the Additive Manufacturing Center (MCAM) of Monash University, Melbourne, Australia, where most of the center’s activities are carried out. Since then, the company has worked closely with Monash and continued to establish operations in the capital of South Australia through a partnership with the University of Adelaide. Its US subsidiary AM Aero is located in El Segundo, Los Angeles. The company has obtained licenses for high-strength titanium alloys and aluminum-alloys developed by Monash University. In addition, Amaero also has an exclusive US distribution agreement “for the world’s fastest laser-based powder bed 3D printer.”

In December 2019, Amaero announced that it had raised 8 million Australian dollars at a price of 20c per share at the time of the IPO and is now listed on the Australian Securities Exchange (ASX). Innovyz, Australia’s commercialization and incubator program, owes in part to Amero’s success before the ASX listing. Therefore, the company will continue to cooperate with Amaero to achieve its short-, medium- and long-term development and growth goals.

Aerospace and automotive metal 3D printing

Many of Amaero’s projects include the use of its PBF and DED metal 3D printing technology to manufacture large-format high-performance metal parts for the aerospace industry. One such project is the 3D printed jet engine developed for Safran Powerplant, a leading French aerospace component manufacturer. In addition, the company has also participated in the efforts of Next Aero and Woodside Energy to create an efficient gas nail engine called “Project X”.

Its PBF metal 3D printer includes a Concept Laser XLine 1000R and two EOSINT 280M. Amaero also has a DED system, the Trumpf 7040 laser battery powder deposition equipment in its workshop, which can produce components up to 4000 x 1500 x 750mm.

Now with a new agreement, the company will focus on developing 3D printing tools for the automotive industry. By reducing the risk of manufacturing defects, Amaero pointed out that by limiting the number of defective products in the casting, machining and assembly processes using the tool, additively manufactured blades can also bring significant cost advantages.

According to Finnin, Amaero first manufactured tool blades 4 years ago, but it has only recently become a strategic focus of the business. The CEO of Amaero explained that the design, manufacturing, and testing of inserts and the components they make will help develop a case study to illustrate the advantages of conformal cooling in the aluminum die-casting process. Finnin added: “Hopefully this case study will pave the way for the implementation of these tool components to mass production. These tool plug-ins are common to die casting tools worldwide. Once this additive manufacturing process is verified, the global There will be plenty of opportunities.”