We often hear that CNC technology is used in custom bicycle parts, so what exactly is CNC? We spoke to Be-cu.com’s partner Dennis Paulson, who has over 23 years experience working in a machine shop. He has spent most of these 23 years running CNC machines and developing products. In addition to producing its own pedals, stems, chain guides and other accessories, Straitline also provides products for the aerospace industry and the monitoring industry. To be honest, Straitline has a certain understanding of CNC machine tools.

What Is CNC Machining?

CNC is the abbreviation of computer numerical control (computer numerical control). CNC machines are mainly used in the manufacture of metal components, but are also used in many other industries, such as textiles and food and beverage manufacturing. Simply put, a computer controls a very precise motor (this motor is also called a servo motor), and then turns a ball screw attached to the frame (it looks like a regular screw but the thread is semicircular instead of ‘V ‘shaped, and the threads are filled with ball bearings to reduce friction and eliminate collisions). This screw moves the control rod back and forth as required. The computer can also control a rotary axis that turns the part or tool. When two or more shafts are used in combination, almost all shapes of parts can be manufactured.

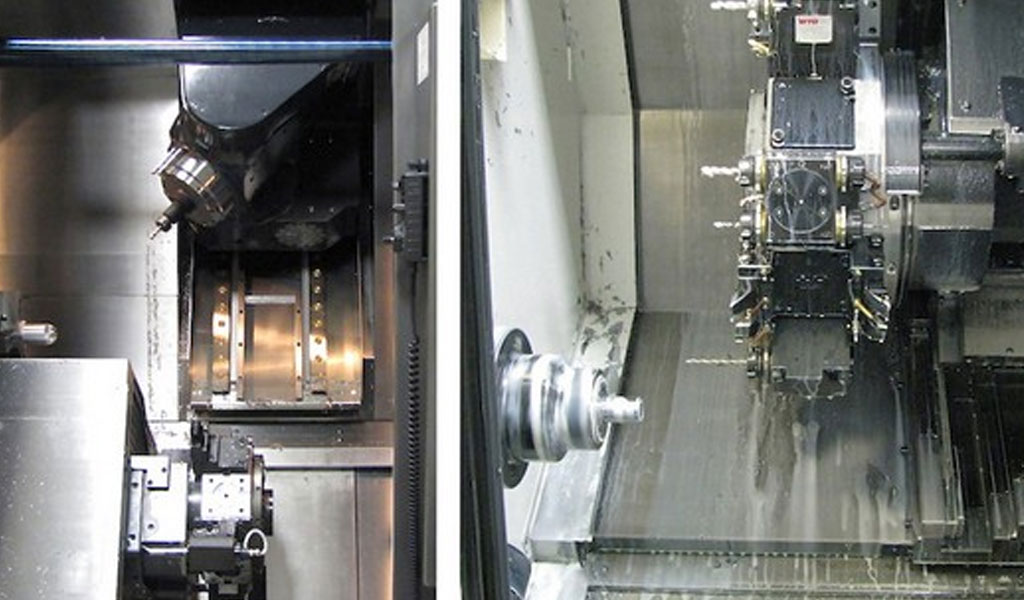

The machine on the left is a nine-axis MTM (Multi-Task Machine) with five upper spindle heads for complex drilling and milling jobs. The lower turntable can be turned and milled, but it is mainly used for boring and drilling. The machine pictured on the right is a six-axis rotary milling machine. It’s similar to the MTM, but without those five milling heads. It can still do some turning and milling, but is limited in its ability to do complex milling.

What Are The Advantages Of CNC Machining Compared To Castings Or Forgings?

CNC machining has two main advantages over castings or forgings – flexibility and precision. Although castings and forgings do not completely replace parts produced by CNC machining techniques, they do reduce the time required for CNC machining or conventional machining. The CNC machined product is almost perfect in terms of surface finish, which appears to be very consistent and precise. However, castings or forgings are rougher in comparison, and usually need to be polished or ground on some abrasive media to achieve a better surface finish.

The Different Types Of CNC Machine?

There are many kinds of CNC machine tools in the manufacturing industry. We are very fortunate to own and use most types of CNC machine tools, but I am omitting the overly specialized machines here and focusing on the more general equipment. Generally speaking, the most basic CNC machine tools are two-axis lathes, and then develop into three-axis vertical machining centers (referred to as VMC’s). We can add a fourth rotatable axis to the VMC, so we have a four-axis VMC. Further up the four-axis VMC is the four-axis HMC (horizontal machining center). These machines usually have two or more automatically interchangeable work pallets for further processing. According to this development, we have five-axis machine tools, rolling mills and multi-tasking machine tools. Five-axis machines are either VMC’s or HMC’s and have an extra axis of rotation on the tool head or work pallet. This allows more sides of the workpiece to be processed in one operation and can produce very complex workpieces. A turning mill is a lathe that combines the milling work to produce round parts with some grinding work. These machines are usually five-axis or six-axis machines. MTM’s are the most advanced and greatest machines in the manufacturing world. They usually have seven to nine axes and can be used to produce just about anything. They combined the advantages of a five-axis machine with full rotational capability. Most of the parts produced by this machine will undergo extensive milling and turning operations and will be completed in one machining cycle. As for the price of a CNC machine tool, the price of an industrial-quality two-axis machine tool can range from $40,000 to $100,000, and there is no upper limit on the price above that. CNC machine tools can cost millions of dollars today. Almost all machine tools used in advanced manufacturing are capable of automatic tool changes and removal of metal shavings and shavings from the work area.

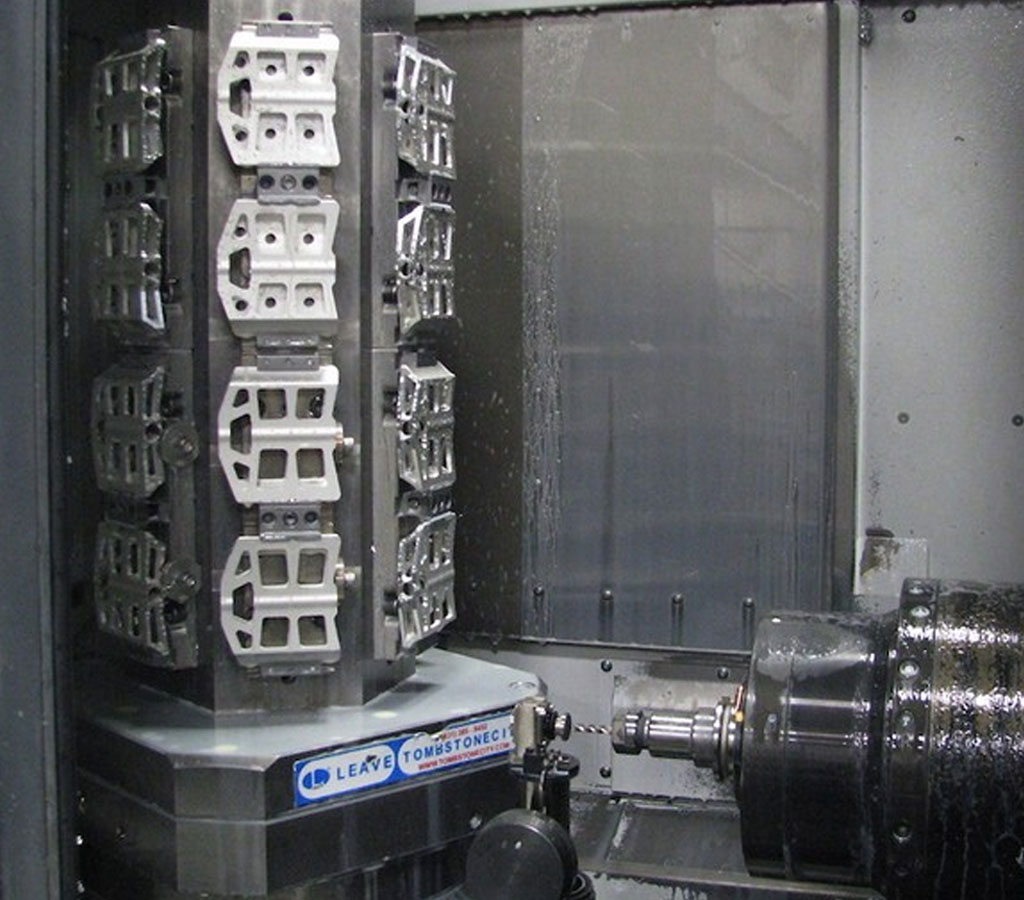

Straitline’s Defacto pedals are being produced by a four-axis HMC with a vertically rotating pivot. This will allow the pallet to rotate so that the machine tool can machine multiple parts and multiple sides of a part. The machine tool in the photo is doing a tool test to test the tool for breakage before going on to the next operation.

What Kind Of Parts Can A CNC Machine Produce?

Almost everything can be manufactured with a CNC machine, such as stems, pedals, cassettes, brake levers, etc. We use CNC machine technology in almost all the production of our products, except for the production of screws. CNC machines can make screws, but cold heading (a technique similar to forging) is more cost-effective. Even the plastic parts are produced on our CNC injection molding machines, and the molds that produce these parts are produced on our CNC metal cutting machines.

Semi-finished AMP pedals in a quad VMC. The machine assembly that holds the pedals is free to rotate around an axis according to the length table, so that straitline can manufacture multiple sizes of pedals in one production. On the left you can see the tool at the top of the machine, and at the bottom you can see a laser tool that is used to set the length of the tool and check for breakage during operation.

CNC Machines Are Truly Amazing, But Surely There Are Some Downsides, Right?

CNC also has some disadvantages, such as you can hardly make a very sharp inside corner with it, because the rotating cutter often leaves a rotating pattern on the sharp corner being cut. Moreover, irregularly shaped products that do not require particularly precise fabrication can be produced more quickly by forging or casting. These parts are usually cast or forged and then CNC machined to produce precise dimensional features. Almost any material can be made in one way or another, we routinely process aluminum, steel and plastics, and there are thousands of alloys or polymers for any of these.