What is the function of the weather station?

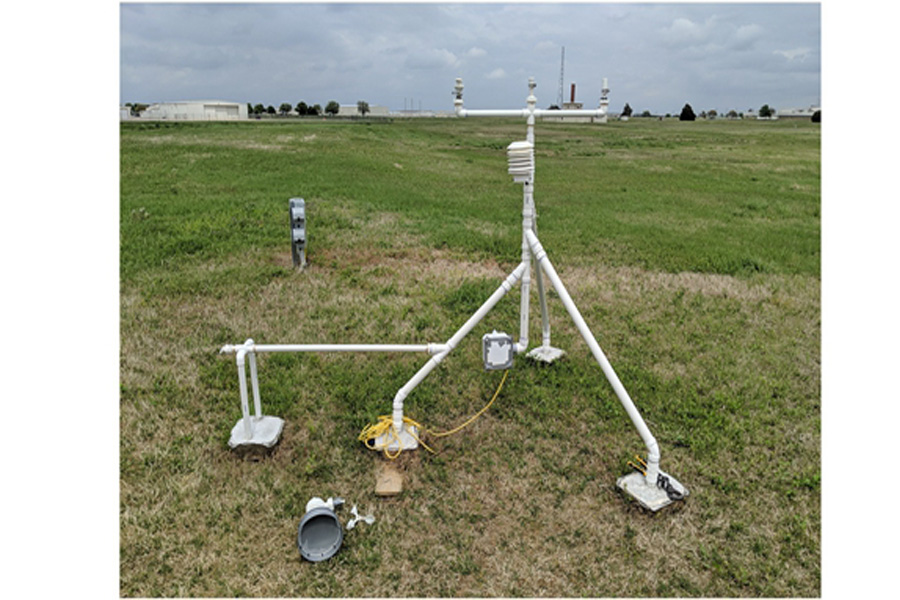

The weather station includes various instruments and sensors designed to monitor factors that affect weather forecasts, including temperature, humidity, wind speed, and solar radiation. The weather station is not only an important tool for news channels, but also promotes research in the fields of agriculture and renewable energy utilization. However, the production cost of commercial equipment can be as high as thousands of dollars, which limits their accessibility when funds are tight. This is where 3D printing comes in, potentially enabling organizations to reduce costs to under $1,000, while bringing manufacturing capabilities to remote areas where it may be difficult to justify parts procurement.

3D printing weather station

Considering that the device will withstand harsh environmental conditions, the team chose ASA as a 3D printing material to supplement the low-cost sensors of the station. Impressively, the weather station had been operating for five full months before the humidity sensor corroded, and some 3D printed parts showed signs of degradation. In general, despite facing rain, snow and temperatures of -10°C to 40°C, the 3D printed parts did not change their shape. According to China 3D Printing Network, in terms of performance, the measurement results of the station can be compared with commercial-grade equipment in the Oklahoma Mesonet (environmental monitoring station network). The device’s sensors are fully capable of accurately measuring temperature, precipitation, UV exposure and humidity. The only instrument that performed poorly was the 3D printed anemometer. Due to its low print quality, it had errors when used to measure wind speed.

The project finally proved that in terms of initial startup costs and maintenance costs, 3D printed weather stations can indeed provide a cost-effective alternative to other sophisticated weather monitoring equipment. Theisen concluded: “If you are talking about replacing two or three of these cheap sensors, instead of maintaining and calibrating a $1,000 sensor per year, then this is a considerable cost benefit.”

This 3D printed UV index sensor uses a plastic cover made of a frozen dinner plate. By the end of the experiment, the glue had turned yellow.

Comment: Of course, this is not the first example of using 3D printing in the development of ecological monitoring equipment. Earlier this year, the French National Development Institute used Formlabs’ SLA 3D printing technology to develop a water pollution sensor for the field. The main goal of the project is to produce “low-cost” equipment for environmental monitoring. The team decided to use 3D printing technology because they wanted to create a user-friendly sensor prototype using commercially available tools.

Elsewhere, researchers at Oak Ridge National Laboratory recently 3D printed the first smart wall of its kind called “EMPOWER”, which has a weather monitoring function. EMPOWER is specially designed for indoor 3D printing, combining concrete additive manufacturing and integrated electronic equipment, which can be used as a room cooling system.