The driving tasks of the future-whether in industry or transportation-place high demands on individual components. The classic manufacturing process of the electric motor quickly reached its limit. Based on traditional manufacturing processes, optimized geometry is usually impossible. As a result, designers are painfully compromised on performance and efficiency. Manufacturing copper coils by 3D printing solves this problem, and the higher copper content in the motor reduces losses and improves the thermal coupling of the windings.

In the market, the German Additive Drives company uses 3D printing to additively manufacture motor stator windings and is expected to significantly improve the performance of parts. The maximum output power of the motor is limited due to its preheating, for example due to the allowable winding temperature. There are usually two levers to increase the power limit: first, to reduce losses with the same power, and second, to improve heat dissipation. The design of the winding plays a major role here because it is the main heat source. The classic round wire winding has many limitations: copper conductors, winding technology and slot geometry must match. The conductors entangled with each other form a strong pattern. In addition, the round wire (the classic conductor shape) does not fit well with the trapezoidal groove in terms of geometry. As a result, each groove is half filled with copper, thereby forming a void. The relatively small conductor cross-section can ensure a large electrical heating loss.

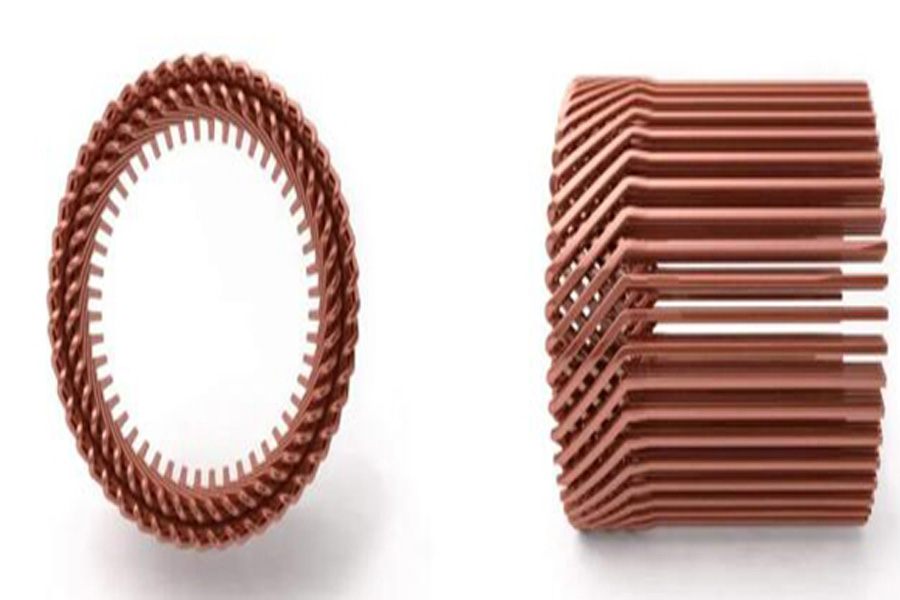

The German Additive Drives company has achieved a higher degree of freedom through 3D printing. Through the powder bed-based SLM selective metal 3D printing process, the copper content in the groove is greater. Physically, this means the largest cross-section of the turns and a smaller resistance. The variable shape achieved by 3D printing is also good for heat dissipation, because each wire is in thermal contact with the so-called laminated core of the coil, so there are no hot spots.

Racing engine with 3D printed motor stator winding

Coils with perfectly matched geometry can maximize copper filling rate

For DC voltage 800 VDC

Forced heat transfer from the winding to the laminated core prevents the formation of hot spots

Variable conductor thickness to reduce current displacement

Developed for best performance

3D printed single coil suitable for electric bicycles

Special function: the motor is an axial flow machine (unconventional motor design)

Perfectly coordinate torque behavior by adjusting the number of turns

Adjustable for different types of electric bicycles

Maximum flexibility, no tool adjustment required

3.3D printed hairpin winding of traction motor

Hairpin winding is a new technology in the field of electric motors. Rectangular copper rods replace the wound copper wires. This process is easier to automate than traditional wire-wound motors, and is particularly popular in the automotive field because it can greatly reduce manufacturing time. 3D printing is extremely used for rapid prototyping and can feed back measurement results to simulation in real time, thus ensuring the required operational performance and improving quality assurance.

Due to the excellent thermal conductivity and reflectivity of copper, this makes it difficult to handle copper metal inside the 3D printer. Although the current selective laser melting (SLM) 3D printing technology can be used to manufacture copper metal powder materials. However, in the process of laser melting of copper metal, the absorption rate is low, and it is difficult for the laser to continuously melt the copper metal powder, which leads to problems such as low forming efficiency and difficult control of metallurgical quality. In addition, the high ductility of copper makes post-processing tasks such as removing excess powder more difficult.

The Fraunhofer ILT Fraunhofer Laser Institute, one of the R&D members of the Aachen Additive Manufacturing Center ACAM, has launched the “SLM Green” solution. The laser used in the current powder bed laser melting technology is usually in the infrared spectrum of light. This is why the low absorption rate of copper occurs, and the energy of light cannot effectively melt the copper metal. Pure copper absorbs 80% of the energy from the electron beam melting process, while only 2% of the energy is absorbed in the infrared laser beam. The laser has become a breakthrough point in copper metal printing.

Germany’s TRUMPF showcased its green copper 3D printing technology at the TCT Asia Additive Manufacturing Exhibition in 2020. With the development of lasers, the application of 3D printed copper has moved towards a benign development trend. According to the market observation of 3D Science Valley, in terms of 3D printing of stator windings, because of the saving of winding tools, 3D printing can economically produce up to 500 Small batch motor stator windings below the station. Lower wire harness resistance, less loss, and shorter winding heads, all of which increase the value of the motor.

The current limit that 3D printed motor stator windings can withstand is about 1 MW, but for commercial prospects, it is more appropriate to focus on the power range of about 100 kW, because this is common in automotive traction motors.