Guide

- How to Calculate 3D Printing Price (SLS, SLA, SLM, MJF, FDM, ETC.,)

- Anodizing vs. Painting: An In-depth Analysis

- 9 Types of 3D Printed Metal Copper Techniques

- 3D Printing Materials and How to Choose the Right One?

- What Is Micro Manufacturing Technology

- Wire 3D Printing: Process, Filament, Printer and Features

- Uncover The Mystery Of CNC Machining

- Huazhong University of Science and Technology has made new breakthroughs in ultrafast laser 3D printing of fine and complex semiconductor micro-nano structures

- In 2025, there will be more than 600 metal 3D printing equipment serving China’s aerospace and other fields

- Looking at the development trend of 3D printing from Formnext 2021

- 3D printed prototype silica gel molds, realizing small batch production of industrial products

- Global architectural 3D printing inventory, no need to move bricks to build a house

- The latest application cases of 3D printing in aviation

- 3D printing everything? Japanese media: Printable buildings, parts, organs and even food…

- 3D printing provides emergency production of anti-epidemic products, global anti-epidemic

Case Studies

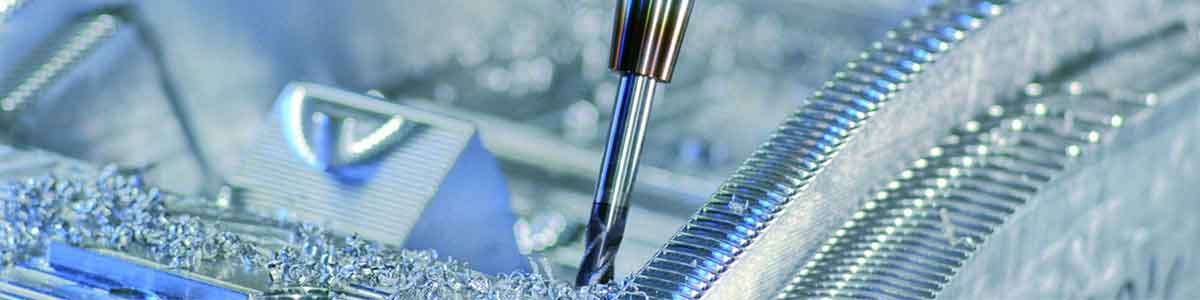

China CNC Machining Services Online Quote

Want to shorten production cycle and reduce cost of your machinery components? Integrated multiple advanced technologies, CNC Machining Services can simplify the manufacturing process and speed up large batch production of machined components, as well as achieve a higher level of accuracy and precision.

Our CNC Machining service will bring your designs into reality in a matter of days. Our simple and easy online quote platform will give you a quick and competitive price for your 3D prints. We ship worldwide and our customer support is happy to advise on any design queries you might have.Precision, accuracy and speed straight from our team of highly trained and passionate cnc machine.

Ordering CNC Machining China online website allows your designs to be processed to exact standards every time, and over 120 machines in PTJ Factory mean that we have incredible replication speed and fast turnaround times. Whether you want fast prototypes with turnarounds as quick as two days, or you are looking for full-scale production for the manufacturing, automotive, or any other industry, and whatever CNC Machining materials you are looking to make use of, PTJ can accommodate your needs.

Cnc Milling

CNC milling (computer numerical control milling) is a CNC machining process that involves removing material from the workpiece by rotating and moving a cutting tool, such as a milling cutter, and positioning the workpiece properly, to produce or finish a custom CNC machining object.

Cnc Turning

There are many types of CNC turning operations for CNC lathe services can be performed on a live tooling lathe in CNC turning factory, including Hard turning, Parting, Facing, Boring, Reaming, Taper turning, Drilling, Knurling, Threading, Grooving, etc., comes in varying tools, cost and set-up time.

Swiss Machining

Swiss machining refers to precision manufacturing process.Swiss CNC machine, also known as Swiss screw machine, Swiss lathe, Swiss automatic and sliding headstock lathe, which is developed in 19th century Switzerland, its initial function is to support the mass production of micro screws.

5 Axis Cnc Machining

5-axis machining is different from 3+2-axis machining. 5 axis CNC machining services allow infinite possibilities of the machined parts. Hook surface machining, unusual shape machining, hollow machining, punching, oblique cutting, and more special processes can be done with 5 axis CNC service.

*All values are taken from the documentation provided by the manufacturer of the special material. PTJ Cnc Machining company. No claims are made to the accuracy of these data, as each individual application may vary. If you have any questions, please contact the manufacturer to give specific product information.

Table of Contents

CNC Machining Material

Cnc Machining Describe

Application : The parts produced by CNC machining have excellent mechanical properties and precision. The metal and plastic used can be reused. We can provide 3-axis and 5-axis CNC milling.

Advantages : excellent mechanical properties, high precision and reproducibility

Weaknesses : higher than the geometric limit of 3D printing

Cnc Machining Features

- Price: Medium

- Delivery Time: <10 days

- Wall Thickness: 0.75mm

- Tolerance: ±0.025-0.125mm

- Process:Cnc Milling,Cnc Turning,Swiss Machining

- Advance:5-Axis Machining, CMM

Metal Cnc Machining

There are many types of metals that can be used for CNC processing, which can be used in many industries. It is not only suitable for one-time prototype parts, but also for mass customization parts.

– Aluminum: 2024, 5083, 6061, 6063, 7050, 7075, etc.

– Alloy: brass 360, 101 copper, 110 copper, 932 bronze, zinc, etc.

– Titanium: grade 2, grade 5, etc.

– Stainless steel: 303, 304, 410, 17-4, 2205 Duplex, 440C, 420, 316, 904L, etc.

– Steel: 4140, 4130, A36, 1018, etc.

Plastic Cnc Machining

It is suitable for various plastics processed by CNC and can be used in many industries. It is not only suitable for one-time prototype parts, but also for mass customization parts.

- – POM (Delrin)

- – ABS (Acrylonitrile

- – Butadiene Styrene)

- – HDPE

- – Nylon

- – PLA

- – PC (Polycarbonate)

- – PEEK (Polyether Ether Ketone)

- – PMMA (Polymethyl

- – Methacrylate or Acrylic)

- – PP (Polypropylene)

- – PTFE (Polytetrafluoroethylene), etc.

CNC Machining Industry

Automotive Parts

PTJ unites mold and injection molding companies to participate in the one-stop service for the design, processing, and manufacturing of automotive products, collaborative production, utilize the expertise of each company, select appropriate production processes, and continue to apply advanced manufacturing technology innovations to automotive parts Components industry. Provide rapid processing and manufacturing services and solutions for industry customers.

Medical Parts

PTJ joins medical processing industry companies to participate in one-stop services for the design, processing, and manufacturing of medical device products, collaborative production, leverage the expertise of different processing and manufacturing companies, select appropriate production processes, and continue to apply advanced manufacturing technology innovations to medical devices industry. Provide rapid manufacturing services and solutions for customers in the medical device industry.

Construction Parts

PTJ unites companies with construction industry service experience in the industry to participate in the one-stop service of design drawing conversion, model processing, and manufacturing for customers in the construction industry, giving full play to the expertise of each service company, selecting appropriate processing technology, and continuing to integrate advanced manufacturing technology Innovation is applied to the construction industry. Provide services and solutions to customers in the construction industry.

Home Appliance Field

PTJ unites companies with manufacturing and service experience in the field of home appliances to participate in the one-stop service of design, processing, and manufacturing of home appliances for customers, collaborative production, give full play to the expertise of each company, select appropriate production processes, and continue to innovate advanced manufacturing technologies Used in the home appliance industry. To provide industry customers with rapid manufacturing services and solutions.

Craft And Jewelry

PTJ unites companies with service and processing capabilities in the industry to participate in one-stop services for the design, processing, and manufacturing of customers’ craft jewelry and cultural and creative products, collaborative production, and use the expertise of each company to choose appropriate production technology to continue to be advanced Manufacturing technology innovation is applied to the craft jewelry industry. To provide industry customers with rapid manufacturing services and solutions.

Model And Toys

PTJ cooperates with model toy processing enterprises in the industry to participate in one-stop service for the design, processing and manufacturing of model toys for customers, collaborative production, give full play to the expertise of each enterprise, choose suitable production technology, and continue to cultivate in the electronic communication product industry. Apply advanced manufacturing technology innovation to the electronics industry. Provide rapid manufacturing services for customers in the model toy industry.

Equipment And Machine

PTJ cooperates with related companies in the industry such as injection molding, mold, blister, machining, etc. to participate in the one-stop service for the design, processing, and manufacturing of customers' equipment, collaborative production, and use the expertise of each company to select the appropriate production process. Deeply cultivate in the instrument and equipment processing industry, and continue to apply advanced manufacturing technology innovations to the instrument and equipment industry. To provide industry customers with rapid manufacturing services and solutions.

Aerospace Parts

PTJ, combined with traditional numerical control machining and modern 3D printing and other technical methods, can easily process high-melting, high-hardness superalloys, titanium alloys and other difficult-to-process materials, and the materials are relatively fully utilized in the 3d printing process. Significantly reduce manufacturing costs; no or only a small amount of follow-up processing is required, which can greatly shorten the production cycle of parts and components, and meet the rapid response needs of aerospace products.

Electronic Parts

PTJ unites high-quality companies in the industry to participate in electronic products for customers: one-stop service for the design, processing, and manufacturing of various electronic devices and electronic products, collaborative production, and use the expertise of each company to select the appropriate production process , Intensively work in the electronic communication product industry, and continue to apply advanced manufacturing technology innovations to the electronic product industry. Provide rapid manufacturing services and solutions for customers in electronic communication products, electronic devices and other industries.

Office Equipment

Through integration, PTJ processes or processes various raw materials, materials, and semi-finished products, produces collaboratively, selects appropriate production processes, reduces production costs, improves product quality, concentrates on the office equipment and office supplies industry, and continues to develop advanced manufacturing technologies. Innovation is applied to the needs of industry customers. Provide prototypes, product diversification, rapid batch manufacturing, and optimized service solutions for customers in the office equipment, office supplies and other industries.

PTJ offers online 3D printing services for china rapid prototyping and production of non-metal and metal 3D printed parts at affordable prices.

- * Supports drawing uploads in file formats “.pdf”, “.jpg”, and “.png”.

- * Supports file uploading and loading of 3D (3D) CAD data “.igs” and “.step”.

- * Supports file uploading of two-dimensional (2D) CAD data “.dxf” and “.dwg”.

- PC

- ST-130

- PA 2200

- CoCrMo

- PA 3200 GF

- ABS M30

- Ceramic

- POM-like

- ULTEMTM 9085

- Paraffin Material

- Polyphenylsulfone

- Polyetheretherketone

- Soft Rubber Material

- Aluminum Filled Nylon

- High Ultra-Fine Plastic

- Mold Steel MS1

- NickelAlloy IN718

- Titanium Alloy Ti64

- White Photosensitive Resin

- Black Photosensitive Resin

- Transparent Photosensitive Resin

- Full Color Photosensitive Resin

- Micro-nano Material

- High Ultra-Fine Plastic

- Full-Color Gypsum Composite Material

GET IN TOUCH OR GET A QUOTE

PTJ 3D Printing

Mobile WhatsApp WeChat:

+86 8288 6112

+86 152 1709 1354

Email: [email protected]

Address: Dongguan City, Guangdong Province, China.