Guide

- How to Calculate 3D Printing Price (SLS, SLA, SLM, MJF, FDM, ETC.,)

- Anodizing vs. Painting: An In-depth Analysis

- 9 Types of 3D Printed Metal Copper Techniques

- 3D Printing Materials and How to Choose the Right One?

- What Is Micro Manufacturing Technology

- Wire 3D Printing: Process, Filament, Printer and Features

- Uncover The Mystery Of CNC Machining

- Huazhong University of Science and Technology has made new breakthroughs in ultrafast laser 3D printing of fine and complex semiconductor micro-nano structures

- In 2025, there will be more than 600 metal 3D printing equipment serving China’s aerospace and other fields

- Looking at the development trend of 3D printing from Formnext 2021

- 3D printed prototype silica gel molds, realizing small batch production of industrial products

- Global architectural 3D printing inventory, no need to move bricks to build a house

- The latest application cases of 3D printing in aviation

- 3D printing everything? Japanese media: Printable buildings, parts, organs and even food…

- 3D printing provides emergency production of anti-epidemic products, global anti-epidemic

Case Studies

3D Printing In Dentistry

We Make Digital Dentistry Possible...3D Printing Dentistry

3D Printing Technology For Dentistry

The cost of tooth restoration and treatment is an important factor that dental clinics and laboratories need to consider. Many prescient dental clinics and laboratories have introduced digital dental technology to improve efficiency and reduce costs. In recent years, dental restoration based on software design has become popular, and many dental clinics, laboratories or professional denture manufacturers have introduced 3D printing technology. Digital oral technology combined with 3D printing brings high precision, low cost, high efficiency, and oral data that conform to the standardized production chain for the dental industry.

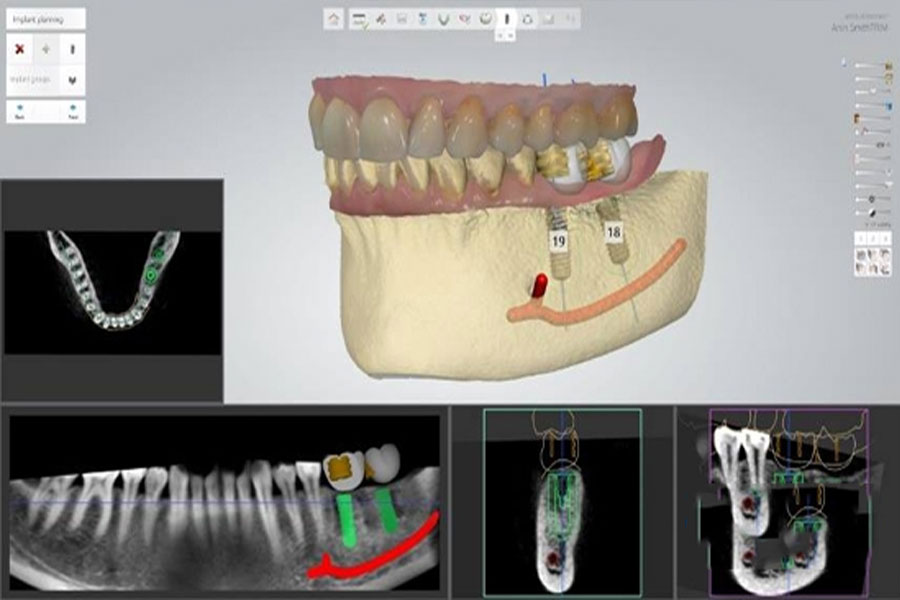

Many dental clinics or laboratories use 3D printers to make patient tooth models. The three-dimensional data needed to make the model can be collected by directly scanning the oral cavity (it takes about 2 minutes to scan the entire oral cavity), or by indirectly scanning the traditional physical model. There are three main functions of the dental 3D model, one of which is to be Used as a mold and uses traditional methods to assist in the production of crowns, dentures, etc. The other two functions are similar to 3D models of orthopedics and tumor surgery, that is, they are used to simulate and plan the surgical process, or to communicate the surgical process with the patient.

Table of Contents

Why Choose Our 3D Printing Dentistry Service?

PTJ meets or exceeds the quality standards of the world’s most demanding industries with our state of the art equipment and quality standards. Our precision and productivity is made possible by our ultimate success factor: the presence of skillful, knowledgeable PTJ experts in Dentistry 3d printing and more additive manufacturing parts.

- No minimum order quantity

- Metal or plastic 3D printed prototype and production parts in 7-10 days

- Precision custom 3D printing parts at affordable prices

- Online free quote in the shortest time

- Single prototypes or complex shapes are both allowed

- A wide selection of metal or plastic materials

- Commercial and industrial-grade 3D printers

- Cooperative supplier assistance project

- Provide a quick solution for small batches of complex prototypes

- Provide a quick solution for small batches of complex prototypes

- We provide with our partner

- 3D printing services for metals and plastics

- Meet the rapid needs of complex prototype designers

The Core Of Digital Design

3D Printing is the core of the new era of digital design. The dental laboratory integrates oral scanning, CAD/CAM design and 3D printing to accurately and quickly generate crowns, bridges, dental artificial stone models, and a series of orthodontic instruments for the dental clinic.

Save time and improve treatment accuracy

With the 3D printer engaged in heavy work, the dental laboratory eliminated the bottleneck of manual modeling and achieved business growth and growth.

Someone once predicted that one day, digitization and automation can be realized from planning to final completion. Now this day has come.

- – Dental laboratories around the world are using 3D printing solutions to:

- – Obtain accurate dental artificial stone models directly from the oral scan digital files;

- – Integrate with 3D dental scanner in the oral cavity and a series of dental design software;

- – Generate realistic dental veneer prototypes—allow patients to test the dental veneers they need before ordering;

- – Generate delivery trays-allowing dentists to calibrate and inlay the veneers of teeth more accurately;

- – The surgical guide and the orthodontic instrument can be obtained directly through the conversion in the software of your choice;

- – Quickly and accurately generate a series of transparent aligners and holders through digital files;

The Advantage Of 3D Printing Dentistry Technology

3D printing is a fast-developing technology in many fields, especially in dental laboratories, thanks to new software, 3D scanners, additive technology and post-processing methods. These methods increase efficiency and cost, and speed up production. Improved quality, but did not benefit. By reducing prices and saving time, doctors and patients benefit a lot, which is one of the small advantages that this technology brings to the industry.

When manufacturing dentures, 3D printing brings many interesting aspects. One of the biggest advantages is improved quality. Previously, using traditional manual workflows, the quality of the finished product was highly dependent on the skills of a given technician. It is very difficult and costly to obtain consistent, high-quality dental products with many potential sources of error.

However, now with 3D printers, it is easy to create fine structures, because components can be built layer by layer, and the process can be controlled through a software program. Compared with plaster model, 3D model is more stable, durable and precise choice.

The lines and edges on the 3D model are kept sharp, so there is no need for the dental technician to worry about fraying them. Compared with the milling model, digital technology simplifies the work process, reduces the error space, and reduces the amount of labor required, thereby saving time and costs in both the laboratory and the practice.

When manufacturing dentures, 3D printing brings many interesting aspects. One of the biggest advantages is improved quality. Previously, using traditional manual workflows, the quality of the finished product was highly dependent on the skills of a given technician. It is very difficult and costly to obtain consistent, high-quality dental products with many potential sources of error.

However, now with 3D printers, it is easy to create fine structures, because components can be built layer by layer, and the process can be controlled through a software program. Compared with plaster model, 3D model is more stable, durable and precise choice.

The lines and edges on the 3D model are kept sharp, so there is no need for the dental technician to worry about fraying them. Compared with the milling model, digital technology simplifies the work process, reduces the error space, and reduces the amount of labor required, thereby saving time and costs in both the laboratory and the practice.

As with all industries, customers always consider important factors in any industry, and so does the dental industry, especially after the industry has introduced new 3D printing technologies.

Therefore, dental 3D printers will create models for patients’ problem areas to prepare for surgery to help them prepare for the upcoming surgery, reduce anxiety and increase patient acceptance. In addition, because the digital element eliminates redundant steps, the process is usually faster, making patient visits faster and easier.

In addition, the product itself is more aesthetically pleasing, the treatment is more accurate, and less invasive, all of which help make the customer experience more pleasant for the patient than before. The patient must come regularly for a month, and the result is not even up to expectations. The patient is not satisfied or dissatisfied with the results.

Saving money is one of the biggest advantages that 3D printers bring to the dental industry. It is a win-win for both patients and doctors, because the cost of operating a dental laboratory can reach US$100,000 per year. Compared to this, the one-time cost of a top 3D printer is about $20,000, including the materials that were initially provided.

Continuous use of materials will affect the cost of the entire life cycle, but it is much lower than operating a dental laboratory. In addition, hiring skilled personnel to produce dental implants is a considerable ongoing investment. All in all, it depends on the workload.

However, dental professionals are not the only ones who save time and money from dental 3D printers. Lower material and labor costs also mean lower prices for patients, and with the improvement of the accuracy and speed of dental 3D printers, the number of visits required by patients has also been greatly reduced.

It is estimated that the total price of dental care may drop by 80% depending on needs. In addition, the higher level of accuracy of this work means happier patients.

3D Printing For Orthodontic Appliance

In addition, dental appliances produced by 3D printing technology are also moving towards application. Compared with traditional orthodontics, 3D printed transparent orthodontics are not only invisible and beautiful, but the size is more suitable for the patient’s tooth condition at each stage of the orthodontic period. Compared with traditional methods that require adjustments based on the experience of the dentist, this correction technique has more advantages. The use of 3D printing technology to make metal crown fixed bridges and other restorations has also become a technology applied in the dental industry. In short, 3D printing brings the efficiency of digital oral technology to the production stage. By combining oral scanning, CAD/CAM design and 3D printing, dental laboratories can accurately and quickly produce a series of dental products such as crowns, bridges, dental models, and aligners.

The Methods Of 3D Printing Dentistry

The 3D printing technologies commonly used in the dental industry mainly include:

- – Photosensitive resin selective curing technology (SLA)

- – Inkjet-Printing

- – Selective Laser Melting Technology (SLM)

But each technology is suitable for different dental products. SLA technology is mainly used in the manufacture of dental surgical guides, temporary crowns and bridges, and resin models cast by lost wax. Inkjet-Printing has been used to manufacture zirconia dental restorations. The materials used in restorations such as crown fixed bridges are mainly dental gold alloys, titanium alloys, cobalt-chromium alloys and stainless steels. Such restorations require high precision and the shapes of the restorations are more complex. SLM technology has great advantages in the manufacture of dental prostheses because of its rapid, direct manufacture of precise and personalized complex metal structures.

PTJ offers online 3D printing services for china rapid prototyping and production of non-metal and metal 3D printed parts at affordable prices.

- * Supports drawing uploads in file formats “.pdf”, “.jpg”, and “.png”.

- * Supports file uploading and loading of 3D (3D) CAD data “.igs” and “.step”.

- * Supports file uploading of two-dimensional (2D) CAD data “.dxf” and “.dwg”.

- PC

- ST-130

- PA 2200

- CoCrMo

- PA 3200 GF

- ABS M30

- Ceramic

- POM-like

- ULTEMTM 9085

- Paraffin Material

- Polyphenylsulfone

- Polyetheretherketone

- Soft Rubber Material

- Aluminum Filled Nylon

- High Ultra-Fine Plastic

- Mold Steel MS1

- NickelAlloy IN718

- Titanium Alloy Ti64

- White Photosensitive Resin

- Black Photosensitive Resin

- Transparent Photosensitive Resin

- Full Color Photosensitive Resin

- Micro-nano Material

- High Ultra-Fine Plastic

- Full-Color Gypsum Composite Material

GET IN TOUCH OR GET A QUOTE

PTJ 3D Printing

Mobile WhatsApp WeChat:

+86 8288 6112

+86 152 1709 1354

Email: [email protected]

Address: Dongguan City, Guangdong Province, China.