Lars Vanmunster, a student of KU Leuven, has developed a process that can improve the surface finish of metal parts that are 3D printed using laser powder bed fusion (LPBF). This technology relies on the application of a second pulsed laser, which can reduce the roughness by 80%. The effect of the project was so great that it awarded Vanmunster a work award.

Due to the splashing of powder particles during the printing process, small bumps are formed on the part, resulting in a rough surface. In turn, the parts must be removed from the printer and finished using techniques such as sanding and polishing. Although in some cases (such as orthopedic implants), a rough surface may be beneficial, but for most parts, it must be further processed to meet the final specifications when printing is not the case. This post-processing is very time-consuming and costly, and in some cases may be a factor in the decision whether to use 3D printing with a given component.

Various methods have been developed to solve the surface finish of metal parts during the construction process. These include mechanical processing, laser ablation and etching, electrochemical processing, etc. One of the problems caused by these methods is the formation of metal chips that can interfere with the construction process. Vanmunster and colleagues encountered an idea in his research, which is usually a problem in previous LPBF research. When experimenting with 3D printed parts using pulsed lasers, it encountered the unfortunate side effect of shock waves interfering with the parts. However, in other fields, such as laser shock peening and foil forming, shock waves from lasers can actually have practical applications.

Vanmunster was a graduate student in the Department of Mechanical Engineering, Manufacturing Process and Systems at Leuven University at the time. He worked with his colleagues and considered using pulsed laser shock waves as a means to improve surface quality. By using 3D Systems ProX DMP 320A with a 500W laser and using a second nanosecond fiber laser, they developed a dual laser method that can automatically perform surface finishing during the printing process. When the first energy source is used to print the part, the second pulsed laser removes the remaining powder by sending a tiny shock wave to the area. This can cause the unsintered powder to be blown away before a laser remelts the outer surface.

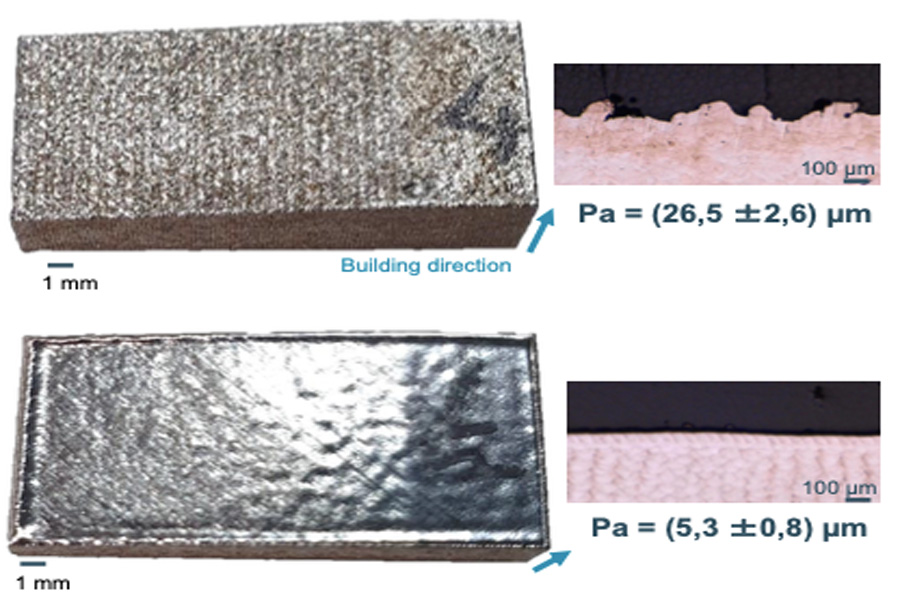

Printed parts and cross-sections before (above) and after (below) the remelting process. The surface is smoother, eliminating the step effect.

This process can reduce the surface roughness by up to 80%, thereby reducing post-processing workload and overall part cost. Vanmunster’s thesis won the “IE NET Master Thesis Award” from the Flemish Association of Engineers. When asked where he inspired the process, Vanmunster said: “The dual laser device was developed by the Additive Manufacturing Research Group at the University of Leuven a few years ago. After in-depth tests and experiments, I discovered the phenomenon of selective powder removal by pulsed laser shock waves. My research focused on the use of Jitka Metelkova’s PhD research in the context of using this setting to reduce surface roughness, which he is using This machine performs hybrid additive manufacturing.”

Vanmunster said that integrating this technology into existing metal 3D printers requires cooperation with the manufacturer itself, but it may eventually make it into the market. Vanmunster said: “From the beginning, we have implemented a dual laser setup in 3DSystems-LayerWise’s commercial LPBF machine. We have worked with their engineers to implement all the required hardware and software modifications. The 3DSystems DMP ProX320 machine was modified within the framework of a large-scale infrastructure project funded by the Lanman government. Therefore, the absorption of our research to industry is very simple. Since the establishment of our additive manufacturing team at the University of Leuven in 1990, this It has always been our DNA.”

In addition to being able to perform smoothing during the build process, there are other benefits of using shock waves compared to post-processing techniques. For example, machining may not always be suitable for smoothing more complex 3D printed parts. The laser-based surface treatment after printing requires a lot of time and labor-intensive steps: remove the part from the machine, clamp it, smooth the laser, and loosen it. All these will result in a lot of additional costs. The advantage of the dual laser device is that it can be processed in-situ, which means no manual and re-clamping are required.

Next, Vanmunster hopes to apply its technology to more complex real-world objects in order to prove its usefulness in industrial products. To this end, he joined the university’s AM team as a doctoral researcher under the guidance of Professor Van Hooreweder, who led the AM team. Vanmunster said: “We will start a new project with many industrial partners, in which we will further explore the possibility of a new dual laser system.”