Guide

- How to Calculate 3D Printing Price (SLS, SLA, SLM, MJF, FDM, ETC.,)

- Anodizing vs. Painting: An In-depth Analysis

- 9 Types of 3D Printed Metal Copper Techniques

- 3D Printing Materials and How to Choose the Right One?

- What Is Micro Manufacturing Technology

- Wire 3D Printing: Process, Filament, Printer and Features

- Uncover The Mystery Of CNC Machining

- Huazhong University of Science and Technology has made new breakthroughs in ultrafast laser 3D printing of fine and complex semiconductor micro-nano structures

- In 2025, there will be more than 600 metal 3D printing equipment serving China’s aerospace and other fields

- Looking at the development trend of 3D printing from Formnext 2021

- 3D printed prototype silica gel molds, realizing small batch production of industrial products

- Global architectural 3D printing inventory, no need to move bricks to build a house

- The latest application cases of 3D printing in aviation

- 3D printing everything? Japanese media: Printable buildings, parts, organs and even food…

- 3D printing provides emergency production of anti-epidemic products, global anti-epidemic

Case Studies

Various Materials And 3D Printing Standards To Meet Your Needs.

The development and breakthrough of 3D printing materials affect the development and application of 3D printing technology

3d printing material properties

Materials are the important material basis of 3D printing technology. On the one hand, the printing process of different principles and the application scenarios of different products determine the choice of specific materials; on the other hand, once the material is selected, it also determines the printing process used and the resulting process constraints. At present, common 3D printing materials include resins, metals, nylons, etc. If you need printing service, please consult our customer service, and the customer service will provide detailed solutions according to your needs.

Equipped and experienced to offer more 3D Printing & material options

3d-printing-china.com customers have the freedom to specify components in hundreds of different metals and alloys, while enjoying a single high standard of confidence in 3d-printing-china.com’s ability to deliver as promised.

Upholding this standard requires an exceptional commitment to manufacturing resources. The wide variety of machining technology options in the PTJ 3D Printing machine library is supported by an in-house tooling capability that adapts tools to the unique characteristics of each material. Behind it all is a staff of engineers and 3D Printing experts with a 10+ year track record of adapting to both new material and tried-and-true materials.

Table of Contents

what material is used for 3d printing

Resin 3D Printing

Objects are created by selectively curing polymer resin layer,material is a liquid photosensitive thermosetting polymer.

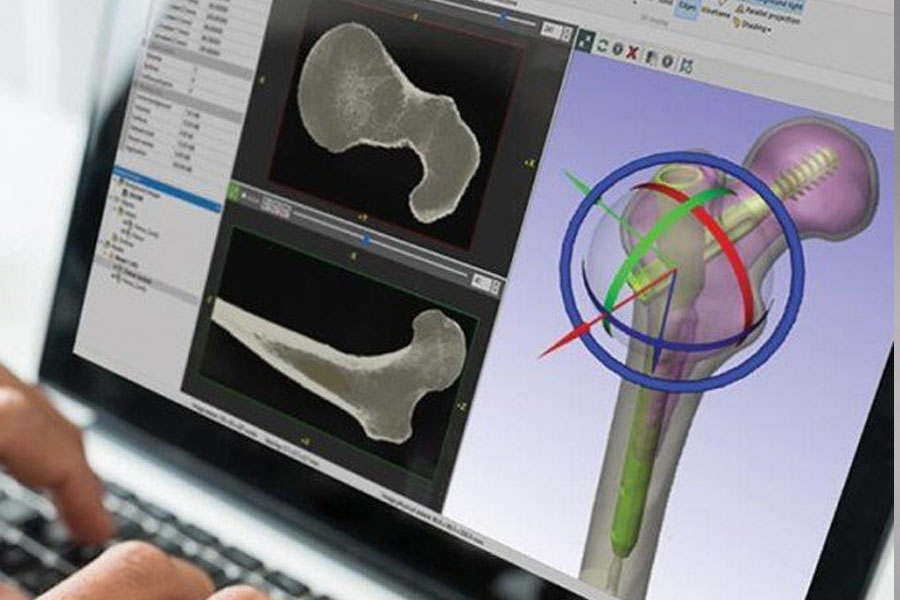

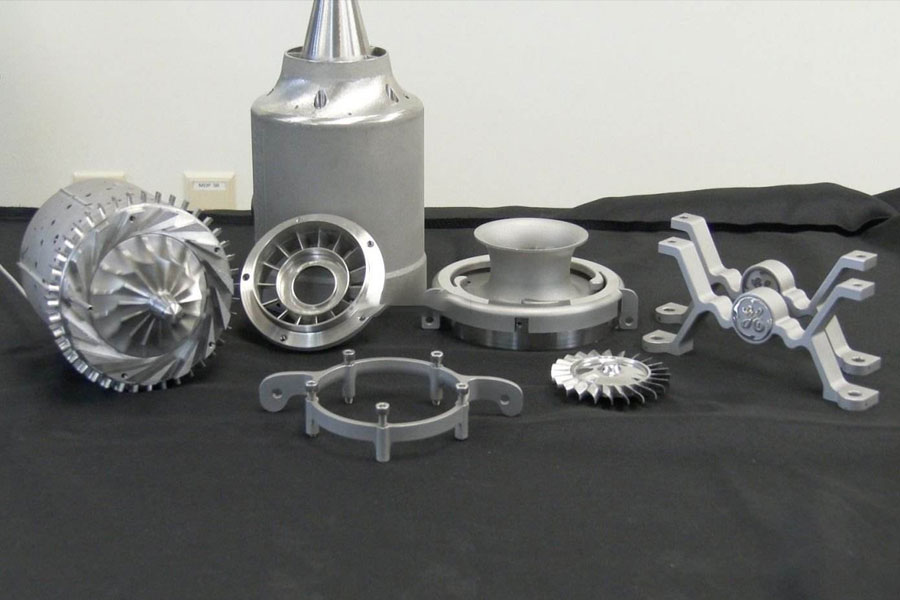

Metal 3D Printing

Almost all metal materials are mainly metal powder, which can become the basic component of metal parts made by 3D printers.

Engineering Plastic 3D Printing

Plastic products are widely used, covering almost every field, and are the most widely used varieties of the five major engineering plastics

Ceramic 3D Printing

These include natural silicate materials such as clay and kaolin, oxide ceramic materials, nitride ceramic materials, and carbide ceramic materials.

Biomaterials 3D Printing

Biomaterials 3D Printing material mainly including biomedical metal materials, biomedical polymer materials, biomedical ceramic materials and bio-derived materials.

Other Material 3D Printing

The characteristics and application scenarios of the product determine the choice of 3D printing materials. Among the printable materials, graphene materials and rubber are also included.

How To Choose 3D Printing Materials ?best material for 3d printing

- SLA Light Curing Rapid Prototyping 3D Printing Technology

SLA Light Curing Rapid Prototyping 3D Printing Technology using photosensitive resin 3D printing materials: milky white texture, good strength, but relatively small toughness, small and thin are easy to brittle fracture, but easy to polish, electroplating, spray paint color. The photosensitive resin is composed of two parts, namely photoinitiator and resin (resin is composed of prepolymer, diluent and a small amount of additives). The amount of photoinitiator and diluent has an important influence on the curing speed and curing quality of the photosensitive resin. The proportion of photoinitiator and diluent is appropriate, not only the curing speed is fast, but the curing quality is also better. Therefore, it is very important to choose large-brand manufacturers, mature and stable photosensitive resin 3D printing materials. In terms of performance of photosensitive resin 3D printing materials, there are also some imported photosensitive resin materials with high strength, transparency, high temperature resistance, moisture resistance, and water resistance. In addition, there is also a composite ceramic 3D printing material (porcelain material alumina (AI2O3) m zirconia (ZRO2), hydroxyapatite (HAP), tricalcium phosphate, which is similar to porcelain with high-resolution ceramic powder and photosensitive resin. (TCP) etc.) Optional.

- FDM Fused Deposition Molding 3D Printing Technology

FDM Fused Deposition Molding 3D Printing Technology using thermoplastic 3D printing materials: relatively speaking, the surface printing layer marks are more obvious and rough. However, the material characteristics of good strength, good willfulness, high impact resistance, strong resistance to solvents, and stable durability are helpful for accurate functional testing, molds and ideal materials for the production of finished products. The 3D printing materials used in this type of 3D printing technology include industrial-grade 3D printing materials and desktop-grade 3D printer consumables.

- Laser Sintering Powder 3D Printing Technology For SLS Selection Area

Laser Sintering Powder 3D Printing Technology For SLS Selection Area using 3D printing materials:PA series nylon 3D printing materials: abrasion resistance, high strength and rigidity, good chemical resistance, excellent long-term unchanging behavior, high selectivity and detailed analysis, bio-compatible conform to EN ISO 10993-1 and USP, conform to EU plastics The directive is approved for use in food contact. The typical application of this material is full-featured plastic parts of the highest quality. But the surface is relatively rough.There is also PA3200GF nylon glass fiber material used in deep drawing dies or any other applications that require specific stiffness, high heat distortion temperature and low wear; aluminum-filled nylon materials typically used in metal appearance and heat-loaded parts. At present, desktop-grade LS laser sintering PA12 nylon powder material is also an option.

- DLP Digital Image Projection 3D Printing Technology

DLP Digital Image Projection 3D Printing Technology using 3D printing materials: independent control of pixels, mask projection layering high-quality and high-precision three-dimensional processing. The printing accuracy is very good, and the surface is very delicate, without polishing and polishing, but there are support points generated in local locations that need to be removed, repaired, and polished. There are a variety of physical materials to choose from in a variety of industries, and a typical application is the 3D printing of red wax for animation dolls.At present, there are many desktop DLP printers that can even freely deploy color 3D printing materials, but the printing accuracy is still far from comparable to industrial grade.

- MJP Multi-nozzle 3D Printing Technology

MJP Multi-nozzle 3D Printing Technology using wax and resin 3D printing materials, multi-nozzle jet cold light curing, can print high-precision small parts. Easy to remove support material. There are multiple different material choices (including soft rubber), typical applications are in lost wax casting such as jewelry, precision machinery, electronic vitality parts, and precision machinery, electronics, and optical parts manufacturing. The performance is close to batch physical manufacturing.

- 3DP-Polyjet 3D Printing Technology

3DP-Polyjet 3D Printing Technology adopts a series of 3D printing engineering plastic 3D printing materials. The typical application is that it can be mixed with a variety of materials (including soft rubber and transparent materials) at one time. Color 3D printing materials.

- 3DP-CJP 3D Printing Technology

3DP-CJP 3D Printing Technology using full-color plaster mixed with 3D printing materials, is currently mostly used for 3D printing portraits and some appearance verification. With the continuous improvement of resin and nylon full-color 3D printing materials, gypsum materials are prone to fracture and rough surfaces, and it is estimated that they will gradually be eliminated and replaced.

- LOM 3D Printing Technology

LOM 3D Printing Technology using film layers to superimpose 3D printing materials, the main materials are paper, plastic film, and metal foil. It is rarely used in the country.

- DMLS, LSM Laser Sintered Metal Powder 3D Printing Technology

DMLS, LSM Laser Sintered Metal Powder 3D Printing Technology EBM electron beam melting 3D printing technology, using metal printing metal materials are available: Titanium Ti64 titanium alloy, mold steel MS1, stainless steel GP1, 17-4, 316, high temperature Nickel alloy IN718, 625, magnesium aluminum alloy AlSi10Mg, CoCrMo cobalt chromium molybdenum alloy, Cobaltchrome SP2 cobalt-based cermet alloy, bronze, precious metals (including gold), etc.

- LOM 3D Printing Technology

LOM 3D Printing Technology using film layers to superimpose 3D printing materials, the main materials are paper, plastic film, and metal foil. It is rarely used in the country.

- The Latest HP MJF 3D Printing Technology

The Latest HP MJF 3D Printing Technology The Latest HP MJF 3D Printing Technology can 3D print gray PA12 and full-color PA nylon materials with high resolution.

- The Latest Desktop LCD3D Printing Technology

The Latest Desktop LCD3D Printing Technology uses visible light 3D printing photosensitive resin material, which is fast and optional.

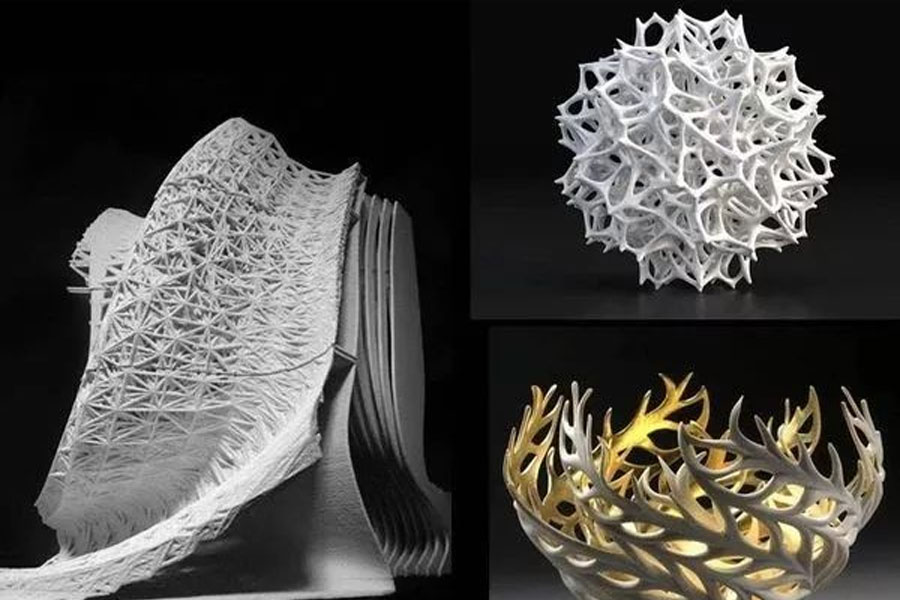

Industrial Grade 3D Printing Materials

Nylon, flexible and rigid photosensitive resin, heat-shrinkable ABS, Peek, PC series engineering plastics, 3D printing metal powder, 3D printing soft glue, silicone, transparent materials, ceramics, stainless steel, mold steel, high temperature nickel alloys, titanium alloys, 3D printer consumables such as paraffin and gypsum composite materials. We will analyze and study the different use needs of customers in different industries to choose and use different 3D printing materials and technologies. 3D printed realistic part models can be quickly applied to almost every industry. Typical applications of 3D printing materials include conceptual models, verification prototypes and rapid modeling, ergonomic research, visual analysis, shape and function testing, functional testing and engineering evaluation.

Desktop 3D Printer Consumables

Small SLA, DLP photosensitive resin material, PA12 nylon powder, polymeric plastic ABS, PEEK, renewable PLA bioplastic, extremely soft and flexible, high-strength and high-hardness Carbon-fibers carbon fiber composite consumables, high-transparent glass-like P-Glass, food Grade heat-resistant PP-PE, L-PA elastic low-temperature nylon, conductive nylon Nylon Conductive, anti-static nylon NYLON ANTI0STATIC, flame-retardant nylon NYLON FLAME RETARDANT, luminous ABS, fluorescence, light change, temperature change, luminous PLA, PP polypropylene, PC Polycarbonate and PETG have high mechanical strength and excellent flexibility and gloss. Transparent, bamboo and wood WOOD consumables, gold-plated, silver-plated, copper, bronze METAL PLA metal consumables, HIPS modified polystyrene can be dissolved in organic solvents. It can be used as a supporting material when printing.

Detailed 3D printing material price and category parameters: XXx

Types of 3D printing materials

There are many types of 3D printing materials and 3D printer consumables. Different 3D printing technologies have their own different materials. Of course, different 3D printers generally use different 3D printing materials.

- (1) In terms of users, there are materials used in industrial-grade commercial 3D printers and personal desktop-grade 3D printer consumables;

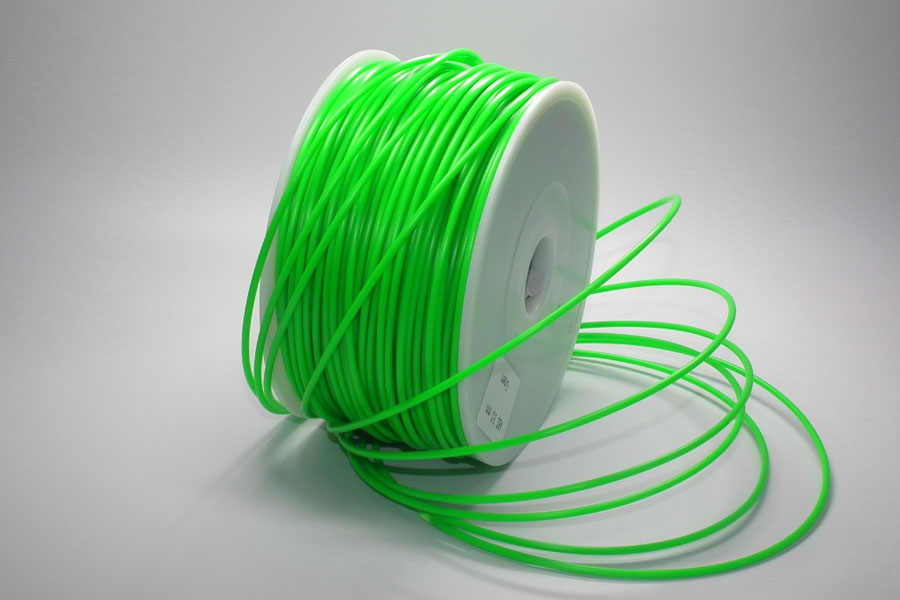

- (2) In terms of physical form, it mainly includes liquid photosensitive resin materials, thin materials, low-melting wire materials (wires) and powder materials;

- (3) In terms of composition, various materials include polymer materials such as plastics, resins, waxes, metal alloy materials, and ceramic materials.

Comprehensive Solution

According to the real needs of customers, formulate the most suitable comprehensive solutions, optimize cost performance, and benefit customers

One-stop Service

It can provide a variety of services such as 3D scanning, 3D modeling, data processing, reverse engineering, 3D printing, post-processing, etc. at the same time

Strong Service Capability

With dozens of experienced foreign trade salesmen, they can provide consulting and follow-up services for customers in different regions at any time

Data Security System

3d-printing-china.com has a strict internal confidentiality system, and can sign specific confidentiality agreements according to customer needs

3d-printing-china.com Case Studies

3D Printing Model Of Wuhan University School Gate

3D Printing Custom Medusa Head For Bar Styling

3D Printing Halloween Bat Masks

3D Printing Nylon Car Exhaust Pipe Model

Luminous Sphere (Outdoor Cultural And Creative Works)

3D Printing Pagoda Model

3D Printing Large Sculptures

PTJ offers online 3D printing services for china rapid prototyping and production of non-metal and metal 3D printed parts at affordable prices.

- * Supports drawing uploads in file formats “.pdf”, “.jpg”, and “.png”.

- * Supports file uploading and loading of 3D (3D) CAD data “.igs” and “.step”.

- * Supports file uploading of two-dimensional (2D) CAD data “.dxf” and “.dwg”.

- PC

- ST-130

- PA 2200

- CoCrMo

- PA 3200 GF

- ABS M30

- Ceramic

- POM-like

- ULTEMTM 9085

- Paraffin Material

- Polyphenylsulfone

- Polyetheretherketone

- Soft Rubber Material

- Aluminum Filled Nylon

- High Ultra-Fine Plastic

- Mold Steel MS1

- NickelAlloy IN718

- Titanium Alloy Ti64

- White Photosensitive Resin

- Black Photosensitive Resin

- Transparent Photosensitive Resin

- Full Color Photosensitive Resin

- Micro-nano Material

- High Ultra-Fine Plastic

- Full-Color Gypsum Composite Material

GET IN TOUCH OR GET A QUOTE

PTJ 3D Printing

Mobile WhatsApp WeChat:

+86 8288 6112

+86 152 1709 1354

Email: [email protected]

Address: Dongguan City, Guangdong Province, China.