Guide

- How to Calculate 3D Printing Price (SLS, SLA, SLM, MJF, FDM, ETC.,)

- Anodizing vs. Painting: An In-depth Analysis

- 9 Types of 3D Printed Metal Copper Techniques

- 3D Printing Materials and How to Choose the Right One?

- What Is Micro Manufacturing Technology

- Wire 3D Printing: Process, Filament, Printer and Features

- Uncover The Mystery Of CNC Machining

- Huazhong University of Science and Technology has made new breakthroughs in ultrafast laser 3D printing of fine and complex semiconductor micro-nano structures

- In 2025, there will be more than 600 metal 3D printing equipment serving China’s aerospace and other fields

- Looking at the development trend of 3D printing from Formnext 2021

- 3D printed prototype silica gel molds, realizing small batch production of industrial products

- Global architectural 3D printing inventory, no need to move bricks to build a house

- The latest application cases of 3D printing in aviation

- 3D printing everything? Japanese media: Printable buildings, parts, organs and even food…

- 3D printing provides emergency production of anti-epidemic products, global anti-epidemic

Case Studies

Multi Jet Fusion 3D Printing(MJF)

Our MJF 3DP Service can produce functional nylon prototypes and end-use production parts within 1 day

What Is MJF 3D Printing?

MJF technology mainly uses two separate thermal inkjet arrays to produce full-color 3D objects. When printing, one of them will move left and right to eject the material, and one will move up and down for spraying, coloring and deposition, so that the finished product will get the desired strength and texture. Subsequently, the two arrays will change direction to maximize coverage and productivity. Next, a thinner is sprayed onto the already formed structure. After that, the outside will heat the parts that have been and are being deposited. These steps will reciprocate until the entire object is printed in layers.

MJF 3D Printing Services Company – MJF 3D Printing Parts Manufacturer

Multi Jet Fusion is an industrial 3D printing process that can produce functional nylon prototypes and end-use production parts within 1 day. Compared with processes such as selective laser sintering, the final part has a high-quality surface finish, excellent feature resolution and more consistent mechanical properties.

Table of Contents

Why Choose 3d-printing-china.com MJF 3D Printing Service

PTJ meets or exceeds the quality standards of the world’s most demanding industries with our state of the art equipment and quality standards. Our precision and productivity is made possible by our ultimate success factor: the presence of skillful, knowledgeable PTJ experts in MJF 3d printing and more additive manufacturing parts.

- No minimum order quantity

- Metal or plastic 3D printed prototype and production parts in 7-10 days

- Precision custom 3D printing parts at affordable prices

- Online free quote in the shortest time

- Single prototypes or complex shapes are both allowed

- A wide selection of metal or plastic materials

- Commercial and industrial-grade 3D printers

- Cooperative supplier assistance project

- Provide a quick solution for small batches of complex prototypes

- Provide a quick solution for small batches of complex prototypes

- We provide with our partner

- 3D printing services for metals and plastics

- Meet the rapid needs of complex prototype designers

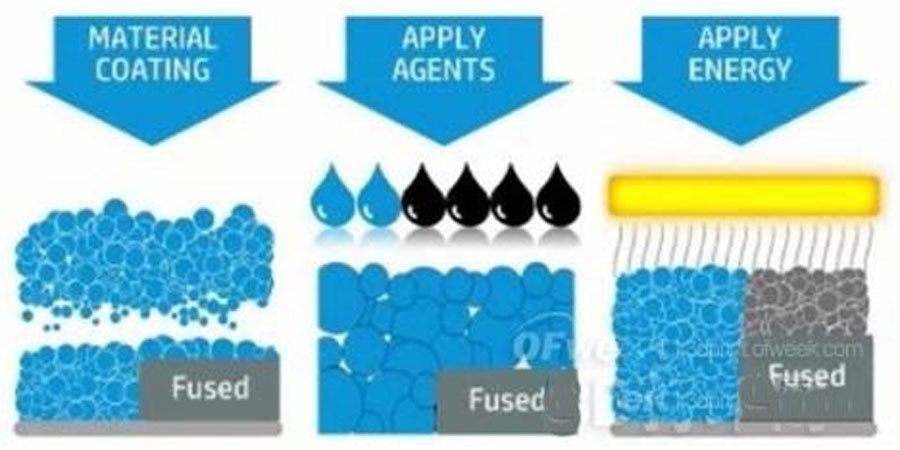

MJF 3D Printing Process

- MJF uses an inkjet array to selectively apply fixers and thinners on the nylon powder bed, and then melt them into a solid layer by heating elements.

- After each layer, distribute the powder to the top of the bed, and then repeat the process until the part is completed.

- After the printing is completed, move the entire powder bed with encapsulation parts to a vacuum processing station, where most of the loose powder is removed by an integrated vacuum.

- The parts are shot blasted to remove the remaining powder, and then sent to the processing department for dyeing or secondary processing.

The Advantages Of MJF

- – This process can simplify the work flow and reduce the cost, realize rapid prototyping and realize the manufacturing of parts and components with breakthrough economic benefits.

- – An open material and software innovation platform that lowers the threshold for use and supports new applications in various industries.

- – MJF3D printing can produce end-use parts with near-isotropic characteristics on demand, and the performance of the products is consistent.

- – The printing speed for small batch orders is fast, and the overall cost is competitive.

3d-printing-china.com MJF Case Studies

3D Printing Puppy Model

3D Printed Transparent Medical Parts

3D Printing Pagoda Model

Custom Luminous Chinese Character

3D Printing Funny Small Dog As Cabbage Shape

3D Printing Wuhan Well-Known Building Hankow Customs House Model

3D Printing Stunning Palace Model

PTJ offers online 3D printing services for china rapid prototyping and production of non-metal and metal 3D printed parts at affordable prices.

- * Supports drawing uploads in file formats “.pdf”, “.jpg”, and “.png”.

- * Supports file uploading and loading of 3D (3D) CAD data “.igs” and “.step”.

- * Supports file uploading of two-dimensional (2D) CAD data “.dxf” and “.dwg”.

- PC

- ST-130

- PA 2200

- CoCrMo

- PA 3200 GF

- ABS M30

- Ceramic

- POM-like

- ULTEMTM 9085

- Paraffin Material

- Polyphenylsulfone

- Polyetheretherketone

- Soft Rubber Material

- Aluminum Filled Nylon

- High Ultra-Fine Plastic

- Mold Steel MS1

- NickelAlloy IN718

- Titanium Alloy Ti64

- White Photosensitive Resin

- Black Photosensitive Resin

- Transparent Photosensitive Resin

- Full Color Photosensitive Resin

- Micro-nano Material

- High Ultra-Fine Plastic

- Full-Color Gypsum Composite Material

GET IN TOUCH OR GET A QUOTE

PTJ 3D Printing

Mobile WhatsApp WeChat:

+86 8288 6112

+86 152 1709 1354

Email: [email protected]

Address: Dongguan City, Guangdong Province, China.