Guide

- How to Calculate 3D Printing Price (SLS, SLA, SLM, MJF, FDM, ETC.,)

- Anodizing vs. Painting: An In-depth Analysis

- 9 Types of 3D Printed Metal Copper Techniques

- 3D Printing Materials and How to Choose the Right One?

- What Is Micro Manufacturing Technology

- Wire 3D Printing: Process, Filament, Printer and Features

- Uncover The Mystery Of CNC Machining

- Huazhong University of Science and Technology has made new breakthroughs in ultrafast laser 3D printing of fine and complex semiconductor micro-nano structures

- In 2025, there will be more than 600 metal 3D printing equipment serving China’s aerospace and other fields

- Looking at the development trend of 3D printing from Formnext 2021

- 3D printed prototype silica gel molds, realizing small batch production of industrial products

- Global architectural 3D printing inventory, no need to move bricks to build a house

- The latest application cases of 3D printing in aviation

- 3D printing everything? Japanese media: Printable buildings, parts, organs and even food…

- 3D printing provides emergency production of anti-epidemic products, global anti-epidemic

Case Studies

3D Printing Orthopedic Implants

3D printed orthopedic implants for personalized precision medical applications

3D Printing In Orthopedic Implants Field

Orthopedic implants is a broad term that covers some artificial devices that are used to replace human joints, such as hips, knees, fingers and shoulders. Looking back at the past, orthopedic implants were mainly for the elderly, but now they are increasingly used by the entire population to treat arthritis or replace damaged joints. With the extension of people's life span and the demand for orthopedic implants by some young patients, there is a high demand for manufacturers to produce long-lasting orthopedic implants.

Table of Contents

Why Choose Our 3D Printing Orthopedic Implants Service?

PTJ meets or exceeds the quality standards of the world’s most demanding industries with our state of the art equipment and quality standards. Our precision and productivity is made possible by our ultimate success factor: the presence of skillful, knowledgeable PTJ experts in Orthopedic Implants 3d printing and more additive manufacturing parts.

- No minimum order quantity

- Metal or plastic 3D printed prototype and production parts in 7-10 days

- Precision custom 3D printing parts at affordable prices

- Online free quote in the shortest time

- Single prototypes or complex shapes are both allowed

- A wide selection of metal or plastic materials

- Commercial and industrial-grade 3D printers

- Cooperative supplier assistance project

- Provide a quick solution for small batches of complex prototypes

- Provide a quick solution for small batches of complex prototypes

- We provide with our partner

- 3D printing services for metals and plastics

- Meet the rapid needs of complex prototype designers

The Opportunity To Be Used For 3D Printing Orthopedic Inserts

As a new type of additive manufacturing technology, 3D printing has been successfully used on a large scale in the field of orthopedics and dentistry. A batch of 3D printed patient customized osteotomy guides, orthopedic implants, dental implants, etc. have been certified by the European Union (European conformity, CE) and the US Food and Drug Administration (Food and Drug Administration, FDA) approved for clinical use. In 2015, the National Food Quality Supervision and Inspection Center also approved China’s first 3D printed hip joint product, and it has begun to be used in large-scale clinical applications.

The Advantage Of 3D Printing Orthopedic Implants

Based on its own digital advantages, 3D printing technology can effectively meet personalized and precise medical treatment and improve efficiency, and has been recognized by professionals and ordinary people. Medical devices prepared by 3D printing not only have the advantages of customization, manufacturability and mechanical properties, but also have a fast preparation process without additional storage and transportation costs; the use of 3D printing technology has short operation time, small trauma area, and success rate. High, the patient suffers less pain, recovers quickly, and has fewer sequelae.

3D Printing Service For Orthopedic Implants

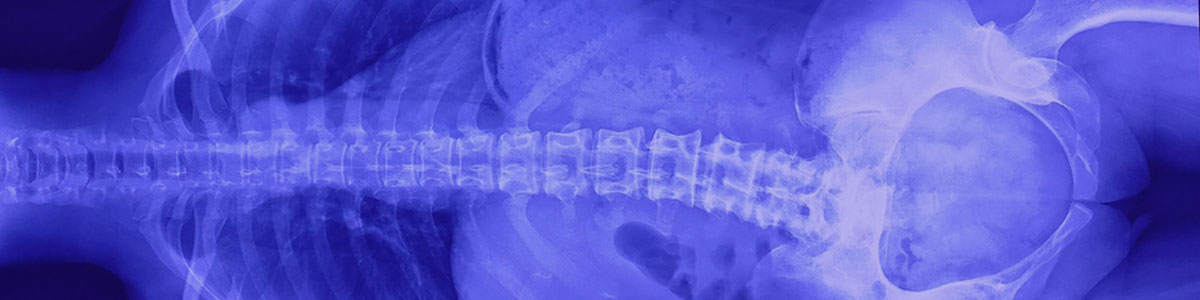

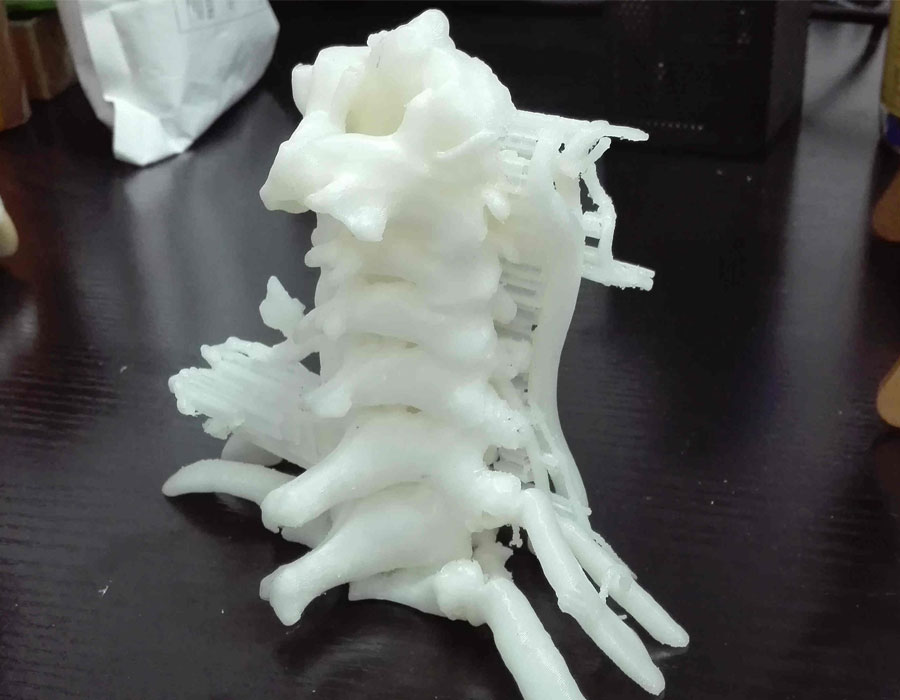

Professional doctors use computerized tomography (CT), magnetic resonance imaging (MRI) and other imaging technologies to reverse or 3D reconstruction to simulate the three-dimensional image of the bones of the missing part, which is used for the 3D printed preoperative guide plate, which is then obtained by layered solid manufacturing technology The bone prototype assists traditional mechanical processing to manufacture bone substitute prostheses that can be implanted in the human body.

3D printing orthopedics commonly used electron beam melting, laser sintering 3D printing metal materials Ti6Al4V, cobalt-chromium alloy and stainless steel powder. Under the computer-aided design, 3D printing can quickly manufacture special-shaped personalized implants, and at the same time, it can manufacture micropores of controllable size. These microporous structures can reduce the elastic modulus of the metal material in the physical part of the implant and reduce the stress shielding; on the surface of the implant, it can promote the osseointegration between the metal and the bone. Bionic artificial bone made of PEEK material is also a good choice.

PTJ offers online 3D printing services for china rapid prototyping and production of non-metal and metal 3D printed parts at affordable prices.

- * Supports drawing uploads in file formats “.pdf”, “.jpg”, and “.png”.

- * Supports file uploading and loading of 3D (3D) CAD data “.igs” and “.step”.

- * Supports file uploading of two-dimensional (2D) CAD data “.dxf” and “.dwg”.

- PC

- ST-130

- PA 2200

- CoCrMo

- PA 3200 GF

- ABS M30

- Ceramic

- POM-like

- ULTEMTM 9085

- Paraffin Material

- Polyphenylsulfone

- Polyetheretherketone

- Soft Rubber Material

- Aluminum Filled Nylon

- High Ultra-Fine Plastic

- Mold Steel MS1

- NickelAlloy IN718

- Titanium Alloy Ti64

- White Photosensitive Resin

- Black Photosensitive Resin

- Transparent Photosensitive Resin

- Full Color Photosensitive Resin

- Micro-nano Material

- High Ultra-Fine Plastic

- Full-Color Gypsum Composite Material

GET IN TOUCH OR GET A QUOTE

PTJ 3D Printing

Mobile WhatsApp WeChat:

+86 8288 6112

+86 152 1709 1354

Email: [email protected]

Address: Dongguan City, Guangdong Province, China.