Microfluidics are fluids that are confined to a small range around behavior, manipulation, and control. Obviously, when dealing with sub-millimeter fluids, precise handling is essential. A team of engineers from the University of California, Davis (UC Davis) has published a research paper in the Proceedings of the National Academy of Sciences. The paper uses a new droplet-based microfluidic system to 3D print flexible materials. “Here, we propose a method of using droplet inclusions to modulate the extruded ink at the printing point,” said abstractly. “Our method represents a continuing trend to adapt microfluidic technology and develop the principles of next-generation additive manufacturing technology.”

Extrusion-based printing is economical and efficient, but it is difficult to use multiple materials to make components with the best softness. Jiandi Wan, an assistant professor of chemical engineering at the University of California, Davis, realized that a typical 3D printer nozzle is no different from the glass capillary microfluidic device that students study in his laboratory. Nozzles. “Most extrusion-based 3D printers use very simple nozzles, and since we have developed these glass microfluidic technologies, we thought,’Why not apply it to 3D printing?”

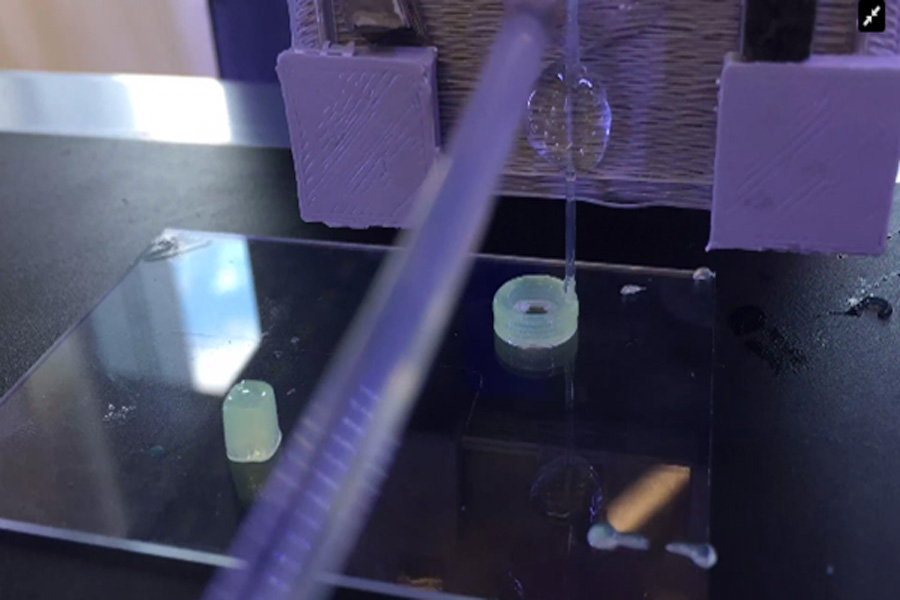

Use water-packed PDMS to 3D print hollow tubes

Wan, together with Hing Jii Mea of the University of Rochester and Luis Delgadillo of the University of Rochester, created a device that encapsulates droplets of an aqueous solution composed of polyethylene glycol diacrylate (PEGDA) in common silicones. Based organic polymer polydimethylsiloxane (PDMS). The device uses a multiphase drip system to produce small PEGDA droplets. In this case, PDMS flows around the dripper, and PEGDA droplets are uniformly introduced into the silicone-based polymer. In this way, the two materials will flow together on any structure that is 3D printed.

The system actually makes it possible to adjust the flexibility of 3D printing structures, which may be very beneficial in applications such as wearable technology, tissue engineering, soft robotics, and bioprinting. The tiny droplets of PEGDA are surrounded by the PDMS material. Once the PEGDA diffuses out, the PDMS will chemically soften-resulting in a more flexible structure.

3D printed ferrofluid in PDMS

Wan explained: “You can also encapsulate other chemicals in droplets to make the entire matrix softer or harder.” In their research, the researchers found that PEGDA droplets significantly changed the “local PDMS chemistry” , Reported that the elastic modulus of the 3D printed structure was reduced by 85%. They also determined that the flexibility of the structure can be adjusted by changing the flow rate and size of the droplets, and that their new droplet-based system can also make porous flexible components. They can actually change the “spatial distribution of droplets” on-site to manipulate mechanical properties, including “water-containing and liquid metal droplets.” They wrote in the paper: “In addition, we have given magnetic functions in PDMS by dispersing ferrofluid droplets, and rationally designed and printed the basic magnetically responsive soft robot actuators as a droplet-based strategy. Demo.”

Because this system makes it very easy to manipulate materials with flexibility, researchers can enjoy more choices in 3D printing microfluidic devices. Wan said: “I think this will open up a new field of research, because the application of mature microfluidic technology to 3D printing represents a new development direction.”

The research team at the University of California, Davis believes that this is the first to use this “droplet-based multiphase emulsion” and is actively studying what other material combinations they can use in the new system to manipulate the chemistry of 3D printed products And mechanical properties.