Guide

- How to Calculate 3D Printing Price (SLS, SLA, SLM, MJF, FDM, ETC.,)

- Anodizing vs. Painting: An In-depth Analysis

- 9 Types of 3D Printed Metal Copper Techniques

- 3D Printing Materials and How to Choose the Right One?

- What Is Micro Manufacturing Technology

- Wire 3D Printing: Process, Filament, Printer and Features

- Uncover The Mystery Of CNC Machining

- Huazhong University of Science and Technology has made new breakthroughs in ultrafast laser 3D printing of fine and complex semiconductor micro-nano structures

- In 2025, there will be more than 600 metal 3D printing equipment serving China’s aerospace and other fields

- Looking at the development trend of 3D printing from Formnext 2021

- 3D printed prototype silica gel molds, realizing small batch production of industrial products

- Global architectural 3D printing inventory, no need to move bricks to build a house

- The latest application cases of 3D printing in aviation

- 3D printing everything? Japanese media: Printable buildings, parts, organs and even food…

- 3D printing provides emergency production of anti-epidemic products, global anti-epidemic

Case Studies

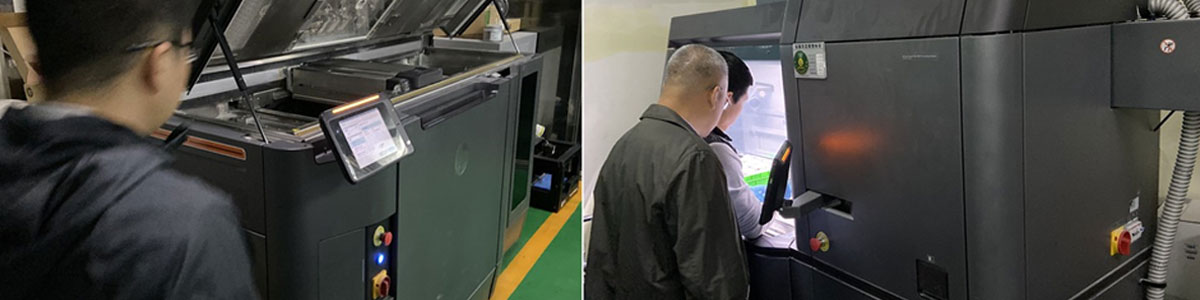

One-stop 3D Printing Solution

3d-printing-china.com has a "full process, full material, full size" supply chain system

3D Printing Service In China

3D printing, also known as additive manufacturing, appeared in the mid-1980s. It is a technology that uses powdered metal or plastic and other bondable materials to construct objects based on digital model files by printing layer by layer. . It is basically the same as ordinary printing. The printer contains liquid or powder and other "printing materials". After connecting to the computer, the "printing materials" are superimposed layer by layer through computer control, and finally the blueprint on the computer is turned into a real object.

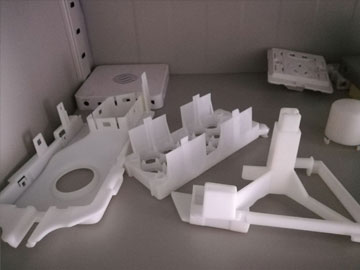

3D printing service is often used to manufacture models in mold manufacturing, industrial design and other fields, and then gradually used for the direct manufacturing of some products, especially for multi-variety, small-batch production orders, the cost-effective advantage is very obvious. The technology has applications in aerospace, medical, automotive, military, machinery and equipment, electronics, energy, consumption, artificial intelligence, cultural creativity, innovation and education, civil engineering and other fields.

Table of Contents

3d-printing-china.com 3D Printing Service List

SLA 3D Printing

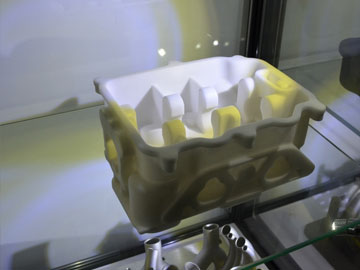

Objects are created by selectively curing polymer resin layer by layer using an ultraviolet (UV) laser beam. The material used in SLA is a liquid photosensitive thermosetting polymer.

SLS 3D Printing

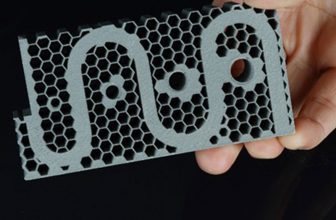

Selective laser sintering (SLS) is a powerful 3D printing technology that belongs to the powder bed fusion process series, which can produce high-precision and durable parts.

FDM 3D Printing

FDM or Fused Filament Processing (FFF) belong to the material extrusion series. In FDM, objects are constructed by selectively depositing molten materials layer by layer in a predetermined path.

SLM 3D Printing

Selective laser melting (SLM) and direct metal laser sintering (DMLS) are two metal additive manufacturing processes belonging to the powder bed melting 3D printing series

DLP 3D Printing

The basic principle of DLP is to use a digital light source to project layer by layer on the surface of the liquid photosensitive resin in the form of surface light, and to solidify it layer by layer.

MJF 3D Printing

Multi Jet Fusion uses an inkjet array to selectively apply fixers and thinners on a nylon powder bed, which are then melted into a solid layer by a heating element.

Why Choose 3d-printing-china.com Service

3d-printing-china.com – As an accomplished 3d printing company and Additive manufacturing shop, PTJ has been specialized in OEM 3d printing, custom 3d printing parts production and rapid 3d printing services China for over 10 years and always maintaining the highest standard in delivery speed and reliable quality of precision additive manufacturing components. With the help of high-level technology and efficient equipment, as well as rigorous attitude, we passed the ISO9001:2015 quality certification, which supports the long-term development of Our SLA 3d printing services, SLS 3d printing services, fdm 3d printing services, DLP 3d printing services, SLM 3d printing services, MJF 3d printing services, 3d printing China custom parts and service, small prototype parts customized, etc. 3d-printing-china.com professional 3d printing involves metal 3d printing, plastic 3d printing, and some difficult materials. Our 3d printing products can be utilized in a broad range of industries.

If you are looking for quality 3d printing services near me, our low cost 3d printing process will review the design, build your quote, assess the cost and get your non-metal or metal fabrication parts into production orderly and efficiently.

Comprehensive Solution

According to the real needs of customers, formulate the most suitable comprehensive solutions, optimize cost performance, and benefit customers

One-stop Service

It can provide a variety of services such as 3D scanning, 3D modeling, data processing, reverse engineering, 3D printing, post-processing, etc. at the same time

Strong Service Capability

With dozens of experienced foreign trade salesmen, they can provide consulting and follow-up services for customers in different regions at any time

Data Security System

3d-printing-china.com has a strict internal confidentiality system, and can sign specific confidentiality agreements according to customer needs

3D Printing Materials

Generally, it includes light-curable resin materials such as acrylic resin, epoxy resin, and polyester resin in a liquid state. Such materials can be cured by polymerization reaction under the irradiation of ultraviolet light. Take the objet260 Connex3 in the industry leader HP 3D printer series as an example. The objet260 Connex3 can be driven by the powerful PolyJet™ technology to spray multiple layers of finely curable liquid photosensitive resin onto the construction pallet, and use ultraviolet light to cure it, and at the same time These thin layers continue to accumulate to create accurate prototypes or production parts.

Mainly include ABS materials, polycarbonate materials and polyamide materials. Here is an example of hp 3D printer that can meet multiple functions and capacity requirements. The hp 3D printer can spray these materials through a single material at a time, or spray multiple basic materials at the same time to print products used in different fields such as manufacturing industry and chemical industry.

The metal materials used in the 3D printing manufacturing process include titanium alloy materials, stainless steel materials, and aluminum alloy materials. This type of material cooperates with hp’ FDM, PolyJet, SLA, SLM and other printing technologies, and the products manufactured are widely used in the field of medical equipment and other fields that have special requirements for materials.

These include natural silicate materials such as clay and kaolin, oxide ceramic materials, nitride ceramic materials, and carbide ceramic materials. These materials have the advantages of high hardness, high temperature resistance, and stable physical and chemical properties that polymer and metal materials do not possess. Therefore, their 3D printing products have broad application prospects in aerospace, automotive, biomedical and other industries.

Such materials are being used in 3D printing enthusiastically, mainly including biomedical metal materials, biomedical polymer materials, biomedical ceramic materials and bio-derived materials. In 3D printing, they can be used in consumer, medical and other fields.

Rubber materials have the characteristics of Shore A hardness, elongation at break, tear strength and tensile strength. Therefore, 3D printed rubber products are mainly consumer electronics, medical equipment, and automotive interior materials.

Graphene materials with excellent optical, electrical, and mechanical properties, and their 3D printing products can replace various traditional materials, and are used in research fields such as nanoelectronic devices, photoelectrochemical cells, and ultralight aircraft materials.

3D Printing Industries

Due to the limitations of traditional processing technology, there are defects in the design of parts and components. We have a professional cross-border technical team to optimize the structural design through the 3D process, and achieve the purpose of simplifying processing while meeting the design requirements.

The advantages of additive manufacturing can make up for the shortcomings of subtractive manufacturing and make processing simple.

Components with complex structures and lengthy procedures will inevitably lead to long processing cycles and affect product delivery. The characteristics of 3D printing technology can improve the delivery cycle.

Compared with the characteristics of large material reduction processing allowance, long process and high precision requirements, 3d printing can play a role in reducing production costs.

3d-printing-china.com can provide a rich selection of 3d printing materials, many of which can replace the materials used in traditional craftsmanship, and are even superior in some functional characteristics.

In terms of personalized customization and small batch production, 3D printing has more advantages than traditional processes, both in terms of processing costs and processing cycles. Especially in the after-sales service for the repair or reprocessing of failed parts after long-term use; and the repair or restoration of the failure of a single part in the assembly.

3d-printing-china.com Case Studies

3D Printed High-Strength Large-Size Resin Medical Orthosis

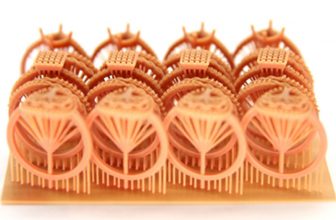

3D Printing Complicated Superalloy Parts

3D Printing Flexible Electronics Materials

Custom Luminous Chinese Character

The Peach Blossom Fan Of 3D Printing

3D Printing Nylon Car Exhaust Pipe Model

3D Printing Personalized Jewelry And Ring

PTJ offers online 3D printing services for china rapid prototyping and production of non-metal and metal 3D printed parts at affordable prices.

- * Supports drawing uploads in file formats “.pdf”, “.jpg”, and “.png”.

- * Supports file uploading and loading of 3D (3D) CAD data “.igs” and “.step”.

- * Supports file uploading of two-dimensional (2D) CAD data “.dxf” and “.dwg”.

- PC

- ST-130

- PA 2200

- CoCrMo

- PA 3200 GF

- ABS M30

- Ceramic

- POM-like

- ULTEMTM 9085

- Paraffin Material

- Polyphenylsulfone

- Polyetheretherketone

- Soft Rubber Material

- Aluminum Filled Nylon

- High Ultra-Fine Plastic

- Mold Steel MS1

- NickelAlloy IN718

- Titanium Alloy Ti64

- White Photosensitive Resin

- Black Photosensitive Resin

- Transparent Photosensitive Resin

- Full Color Photosensitive Resin

- Micro-nano Material

- High Ultra-Fine Plastic

- Full-Color Gypsum Composite Material

GET IN TOUCH OR GET A QUOTE

PTJ 3D Printing

Mobile WhatsApp WeChat:

+86 8288 6112

+86 152 1709 1354

Email: [email protected]

Address: Dongguan City, Guangdong Province, China.