Swiss medical company Medacta successfully obtained the approval of the U.S. Food and Drug Administration (FDA) and CE certification, and officially began to commercialize the 3D femoral conical vertebral body for revision knee arthroplasty.

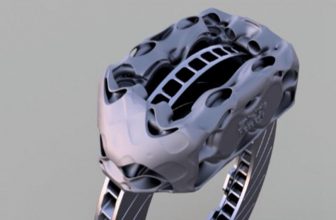

DMetal is an advanced biological material, manufactured using EBM 3D printing technology. Based on the clinical success of the 3DMetal tibial cone, the femoral cone can be used for structural support in the area of bone defects, for fixing revision implants, and has been shown to be used in conjunction with Medacta’s GMK Revision and GMK hinged knee joint system. The printed implant has a high coefficient of friction and a high level of porosity, addressing the need for initial stability and long-term biological fixation.

Dr. David W. Manning, vice chair of orthopedic surgery at Northwestern University’s Feinberg School of Medicine in Chicago, Illinois, and the designer of 3DMetal femoral cones, said: “Medacta’s 3DMetal femoral cones are versatile. The clinically-proven 3DMetal technology is useful for those who wish to restore metaphyseal and metadiaphyseal structures. The structure is very easy to use for the surgeon who built the revised TKA structure from it. Fitting these cones into Medacta revision products allows me to efficiently and reliably deal with the most difficult femoral revision schemes.”

3DMetalTM Femoral Cone is characterized by Medacta’s patented three-layer structure. The middle full-density layer can prevent cement from seeping out of the outer pores and improve the mechanical properties of the implant. The innovative interconnecting pore structure of these implants is similar to natural cancellous bone, and can be directly mechanically and functionally connected to the bone.

This new implant further adds to Medacta’s knee replacement product line, giving more options for revision surgery and complex cases.