3D printing tableware for the disabled

This is a multi-purpose simple tableware support that can help those with limited palms. It can be customized to fit any hand and fork or spoon. For comfort and cleanliness, it does not use Velcro straps; it is just a 3D printed part.

The designer recommends printing the model with a layer height of 0.2 mm, which takes about two and a half hours to complete.

Hold a card

Do you know someone who likes to play card games but has agility challenges? 3D print these handhelds to include everyone, or give them as gifts. A nice shelf is also included, which makes it easier to put your hands down while still being able to see what’s inside.

The designer recommends using a utility knife to clean the narrow gaps after printing, and use sandpaper for smoothing.

Hold the pen

If someone’s finger is weak and writing with a pen or pencil is challenging, then this is the print you want! It basically adds to the foundation of your choice of writing instrument, making it easier to hold and use. The model was designed for Mutual de Seguridad in Chile, and the program aims to use innovation and development to help those in need.

After printing, the designer recommends putting the 3D printed model in hot water. In this way, a pencil or pen can be easily loaded because it is tight.

Rubik’s Cube

It may not look like it, but in fact the device is a Rubik’s Cube for blind people or half vision. Colors are replaced by numbers on the sides, and the goal is to make all the same numbers face the same direction.

The designer recommends printing with a layer height of 0.2 mm and a filling degree of 10%. They need about two and a half hours to print.

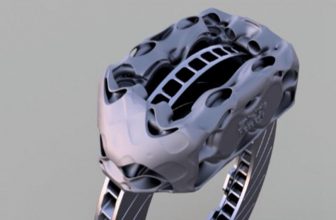

Rings with interesting personality

This interesting and creative ring design is very suitable for people with autism. The wearer can use it as a nonverbal signal to indicate whether they are willing to make contact with the body, especially a hug.

When printing, the designer recommends that you place your hands away from the bottom plate so that you do not need to use the support frame.

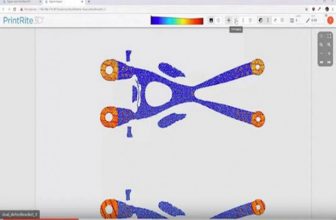

Typing touch screen

This model is very useful for anyone who has lost or limited palm control and finger movement. With this help, it should be easier to use the touch screen or keyboard. This is another project planned by Chiliean Mutual de Seguridad.

The designer recommends using a layer height of 0.3 mm and filling it with 100%, but do not use any patterns. It is also recommended to use a heat gun or hot water (but not too hot to cause injury) to adapt the design to the shape of the wearer’s hand.

Toilet paper dispenser

Usually, toilets for the disabled have a complicated mechanism for distributing toilet paper. With this simple 3D printing, you can attach a roll of toilet paper to the armrest for easy use.

If there is no support when printing, the designer recommends using Dremel or a craft knife to clean the locking mechanism. It should also print out 20% filler and 0.2 mm layer height.

Can opener

This design makes it easier to open cans without the need to pull hard or use a knife. This is not only for people with finger or hand challenges: the elderly, children, or people with weak grip or arthritis can also benefit. It is recommended to use a layer height of 0.2 mm. In this case, the model will take about 3 hours to print.

Convenient water dispenser

When you are in a wheelchair, you get thirsty easily! Now you can 3D print this bottle holder design and attach it to the wheelchair, creating, customizing and assembling is very simple. There is even an instructional video to provide more help. The designer recommends using 20% filler and support.

Expression of love

Express your love for deaf people by printing the “I love you” sign language in “American Sign Language”. The model even has a small hole, which can be hung on a necklace or made into a necklace. The design is super simple; no rafts or supports are required.

Wheelchair ramp

Those who have to rely on wheelchairs to travel often face barrier-free challenges. Even though many countries have made great efforts to solve this problem, having accessibility with you is not a bad idea.

The two-part wheelchair “ramp” makes it easier for people to get on and off the curb. It takes about 26 hours to print, you can check the blog post for details.

Zipper

Never use your teeth (or anything else) to open or close the zipper! For those who have challenges with hands or arms, you will be very satisfied with this fast and convenient printing. Continue to do this, as it fits most zippers.

There is even a video detailing how to develop design as part of an assistive technology challenge.

One manufacturer pointed out that there is no custom procedure for this design, so you can do that now. It is recommended that you print the model at a fill rate of 100%.