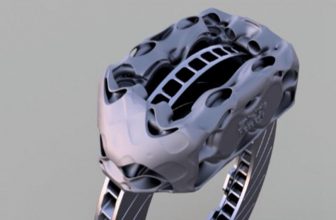

Newly launched a 3D printing material-Somos PerFORM, which is a fast processing and stereo light curing molding resin, has excellent high temperature resistance (high temperature resistance 200-260 degrees), can be manufactured with high characteristic resolution Sturdy, tough and precise parts.

Somos® PerFORM resin product description

Somos® PerFORM produces sturdy, tough, and high-temperature composite parts that are particularly suitable for mold and wind tunnel testing applications.

Somos® PerFORM is the lowest viscosity of all composite 3D light-curing resins. Using Somos® PerFORM can make parts more quickly, and the manufactured parts are easier to post-process and clean, and have excellent sidewall quality, which can achieve unparalleled details. Resolution.

It is particularly suitable for manufacturing strong and tough parts with excellent high temperature resistance, including wind tunnel models for aerospace and automotive applications, and rapid molds for injection molding.

Main advantage

- • Excellent detail resolution

- • Fast, easy processing and surface treatment

- • Excellent high temperature resistance

- • Mould, rapid injection mould

- • Wind tunnel testing

- • High temperature test

- • Electrical enclosure

- • Car shell

PerFORM physical properties table

Mold application:

Previously, the general SLA printed products can also be used to make silicone molds, but due to mold material problems, silicone molds are not durable, and accuracy will decrease as the frequency of use increases. Generally, they cannot be used for about 15-20 times. NS. And because of the characteristics of silicone molds, the materials it can make are also limited. The high temperature resistance of PerFORM material makes the 3D printed product as a prototype mold more abundant. It can not only make other molds than silicone molds, but it can even be used as a mold to cast some low-temperature materials.

Application areas:

Higher heat distortion temperature (HDT), up to 268°C (514°F) (in ASTM standard test, the spline received an external load of 0.46MPa, and the heat distortion temperature can reach 268°C), making PerFORM particularly suitable Manufacturing strong and tough parts with excellent high temperature resistance, including wind tunnel models for aerospace and automotive applications, and rapid molds for injection molding. F1 (parameters | pictures) racing cars have already begun to use PerFORM materials for wind tunnel model testing. Toyota Motorsport GmbH (Toyota Motors) is also using this material to test new prototype parts for high-performance racing cars, giving them a competitive advantage in design and testing. Moreover, with the help of this material, TMG is now able to produce injection molds and expand new business areas in the automotive industry.

In addition to applications in aviation, automotive and other fields, PerFORM materials will also be used in the home furnishing field. For sanitary products, it is recommended to use PerFORM material. The high temperature resistance can make it flow without pressure. In addition, the material has good electroplating characteristics, which can customize sanitary products and get rid of the same boring.

The 3d-printing-china.com 3D printing platform has always adhered to the purpose of providing customers with 3D printing solutions of “full materials, full processes, and full size”. Now it has launched PerFORM materials. On the one hand, it updates and expands the material library in a timely manner. On the other hand, it relies on PerFORM material super High temperature resistance and excellent detail resolution can provide customers with more post-processing, obtain more effects, and meet more needs of customers.

Customers in the Asia-Pacific region who need to manufacture automotive shells, electrical enclosures, rapid molds or ultra-high temperature materials can contact us for cooperation.