Guide

- How to Calculate 3D Printing Price (SLS, SLA, SLM, MJF, FDM, ETC.,)

- Anodizing vs. Painting: An In-depth Analysis

- 9 Types of 3D Printed Metal Copper Techniques

- 3D Printing Materials and How to Choose the Right One?

- What Is Micro Manufacturing Technology

- Wire 3D Printing: Process, Filament, Printer and Features

- Uncover The Mystery Of CNC Machining

- Huazhong University of Science and Technology has made new breakthroughs in ultrafast laser 3D printing of fine and complex semiconductor micro-nano structures

- In 2025, there will be more than 600 metal 3D printing equipment serving China’s aerospace and other fields

- Looking at the development trend of 3D printing from Formnext 2021

- 3D printed prototype silica gel molds, realizing small batch production of industrial products

- Global architectural 3D printing inventory, no need to move bricks to build a house

- The latest application cases of 3D printing in aviation

- 3D printing everything? Japanese media: Printable buildings, parts, organs and even food…

- 3D printing provides emergency production of anti-epidemic products, global anti-epidemic

Case Studies

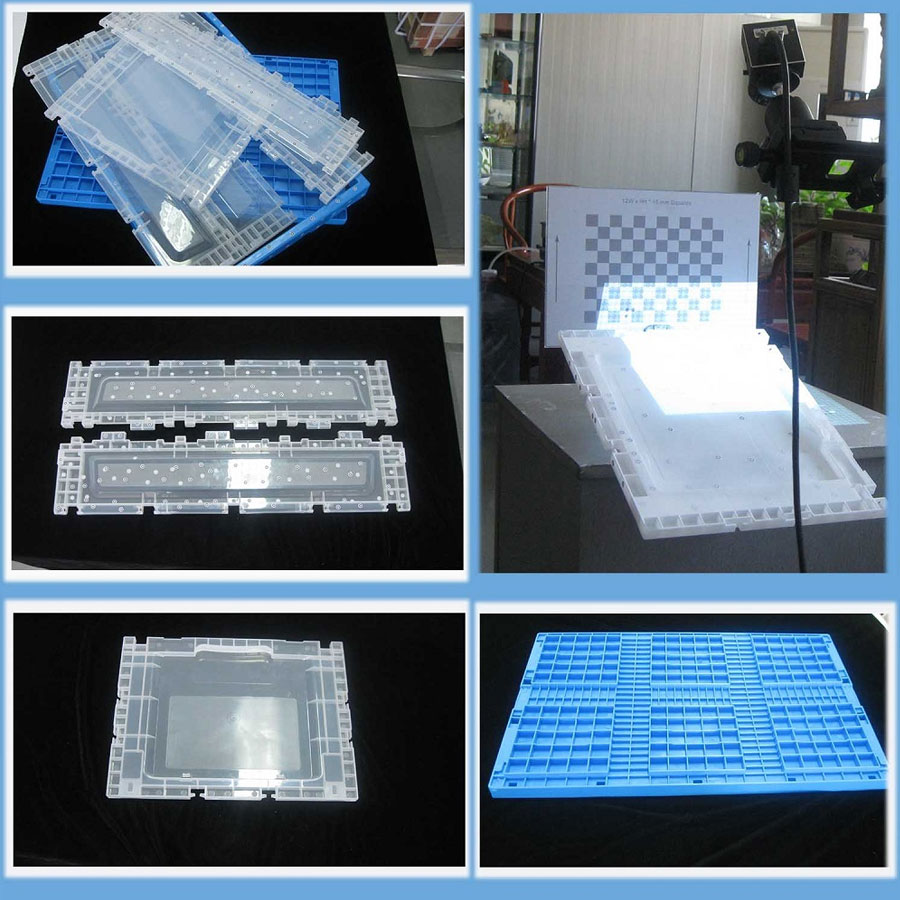

One-stop 3D Scanning Solution

Scan the shape, structure and color of the object to obtain the spatial coordinates

What Is 3D Scanning?

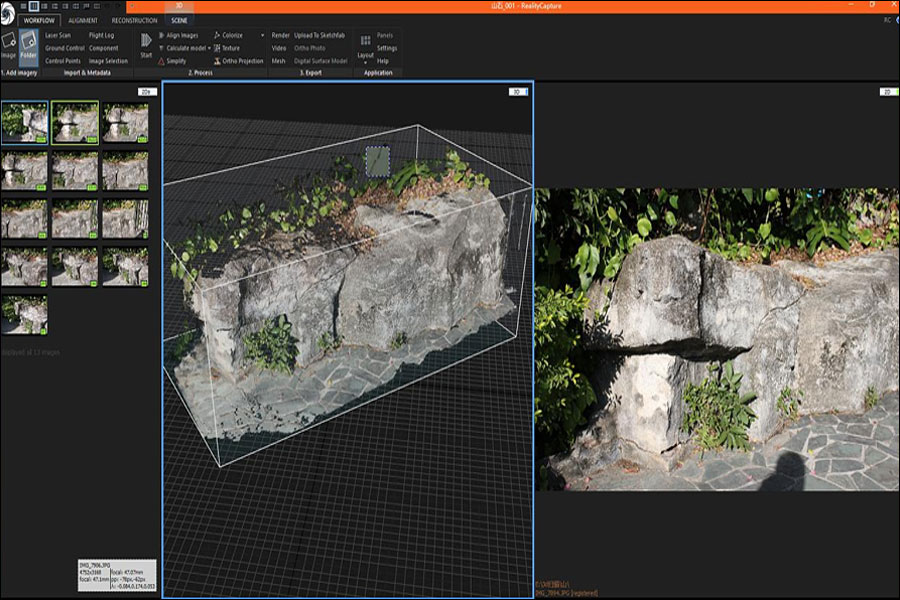

3D scanning is a process of obtaining product CAD models from existing physical models (existing products, hand touches, clay sculpture models, etc.), that is, using 3D scanner 3D scanning and various digital technologies and CAD technologies The process of reusing 3D software to construct CAD models to clone or create physical products is characterized by fast, convenient, and intuitive, and is especially suitable for product design with complex geometric shapes and many free-form surfaces. 3D scanning design, also called reverse engineering.

Table of Contents

China Top Online 3D Scanning Service

Want to quickly obtain the three-dimensional data of the product? Can’t find the CAD drawing of the product? Need to do finite element data analysis? Need to scan the model to establish 3D data for inspecting the surface of the part? Obtaining 3D data and models of historical buildings, ancient villages, and archaeological sites? All your needs, in 3d-printing-china.com, can provide the best solution in a short time.

We use advanced 3D scanners and have the most complete 3D scanning, reverse engineering, and reverse inspection service team. And provide measurement, 3D surface construction, product inspection services.

Why Choose Our 3D Scanning Service

Comprehensive Solution

According to the real needs of customers, formulate the most suitable comprehensive solutions, optimize cost performance, and benefit customers

One-Stop Service

We can also provide a variety of services such as 3D scanning, 3D modeling, data processing, reverse engineering, 3D printing, post-processing, etc.

Data Security System

We have a strict internal confidentiality system, and at the same time, we can sign specific confidentiality agreements according to customer needs

The Service Type Of 3D Scanning Service

Which scanning technology do I need to choose?

Portable 3D Scanning

The portable scanning speed is fast, the data is accurate, and it is equipped with texture information. It can work in some complex environments and small spaces. It can quickly capture the shape of objects with high resolution and truly restore the surface color of the object.

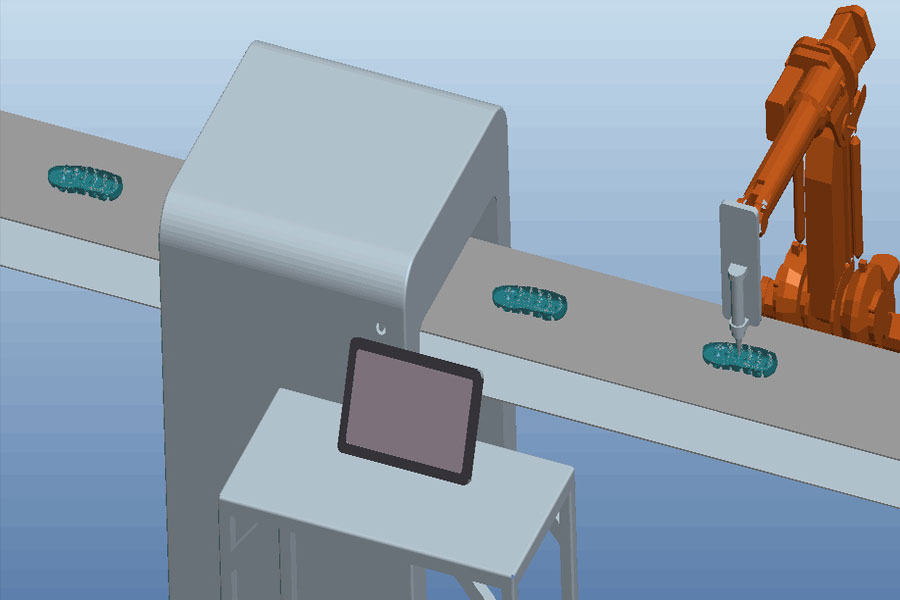

Industrial 3D Scanning

3D industrial scanners according to the different scanning methods. We will understand the scanning scene environment and data requirements according to the actual situation of the customer, and choose comprehensive solution & provide one-stop service

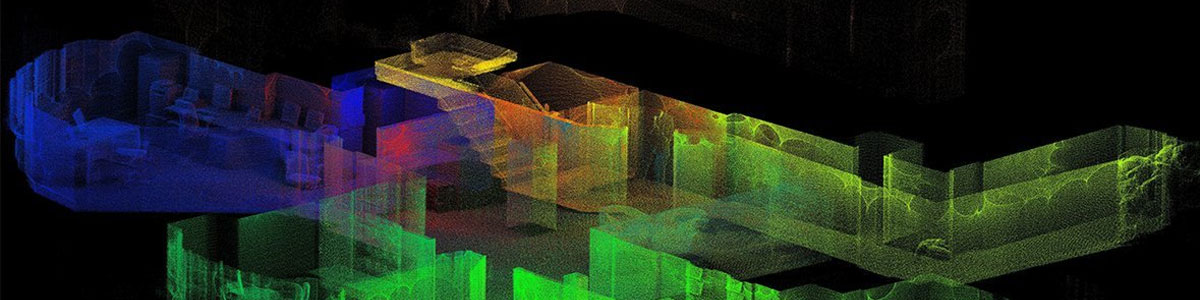

Large Scene 3D Scanning

For the 3D data collection of large-scale archaeological sites, ancient villages and historical buildings, the 3D surveying and mapping of large-scale factories, infrastructure projects, and bridge pipelines all require large-scale laser scanning equipment to provide services.

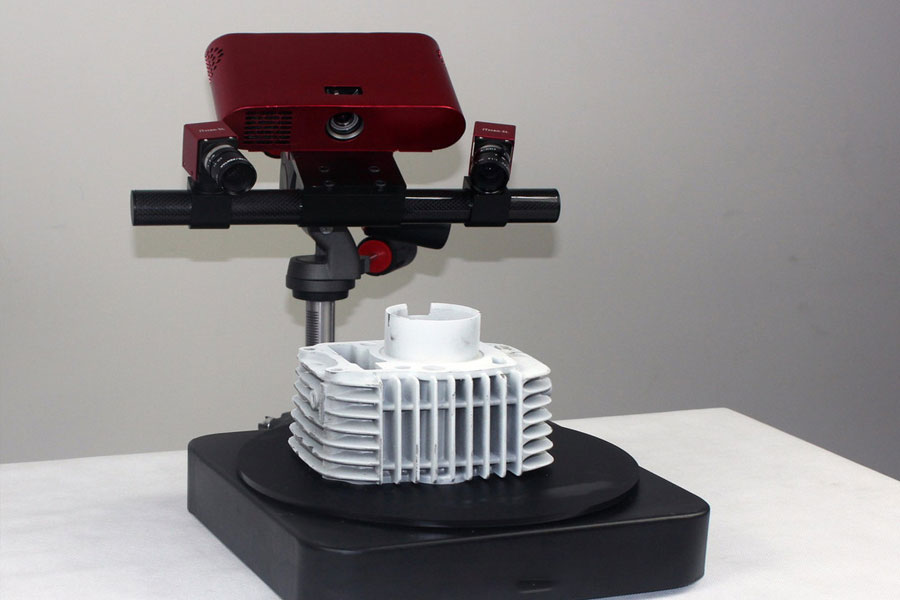

U-level high-resolution Atos 3D scanner

The accuracy can reach up to 0.007mm, measuring parts of different sizes. When using the highest resolution, it reflects the details of small parts measuring as small as 38 mm, or extremely fast scanning processing measures large objects as large as 2 meters. It can even measure objects as large as 30 meters, while maintaining extremely high local resolution. It can be used for full-size inspection, size verification, reverse engineering, and direct rapid prototyping 3d printing or precision carving. To meet high-end customers, high-precision product copying, design, and testing.

- – Measuring point: 2×5000 000

- – Measuring area: 38×29-2000x1500mm2

- – Measuring point distance 0.01-0.62mm

Smart Handheld Laser 3D Scanner

Intelligent, portable, true high precision, industrial measurement accuracy 0.02mm 0.05mm resolution, third-party traceable certification

Scan the object in all directions. It is not constrained by factors such as component size, material, color, complexity, etc.

Intelligent grid creation, seamlessly docking with mainstream 3D software, improving work efficiency. Used in reverse design simulation, quality control, maintenance and repair, cultural heritage protection, film and television multimedia, VR AR applications, education, medical rehabilitation.

- – Scanning area: 275x250mm

- – Measurement speed: 480,000 measurements/sec

- – Resolution: 0.05

- – Accuracy: 0.02mm

- – Volume accuracy: 0.02mm/m

- – Depth of field: 250mm

- – Output format: .stl, .ply, .txt, .asc, .xyz

Reverse 3D Inspection

The organic combination of optical and contact measurement

Using the contact probe can quickly and effectively complete tasks such as measurement of difficult-to-measure areas, direct comparison with CAD data, detection of primitives, single-point rapid measurement, and online alignment.

Automatic photogrammetry system

The use of high-resolution photogrammetry cameras, with a current resolution of up to 29 million pixels, and equipped with a specially developed optical system, effectively expand the measurement range and shorten the working distance.

Integrated and traceable measurement and inspection application software

Software with traceability is used to control the measuring head, process the 3D point cloud, edit and post-process various data, etc.

Mobile human body 3D scanning system

The self-developed 3D scanning system uses a high-resolution photogrammetry camera to complete the full-color scanning and recording of the human body and any expressions in 0.01 second, and can be used for full-color model 3D printing.

3d-printing-china.com Case Studies

The Peach Blossom Fan Of 3D Printing

3D Printed Medical Sanitary Metal Masks Model

Custom Luminous Chinese Character

3D Printing Moon LED Lights

3D Printing Handheld Electronic Machinery Housing

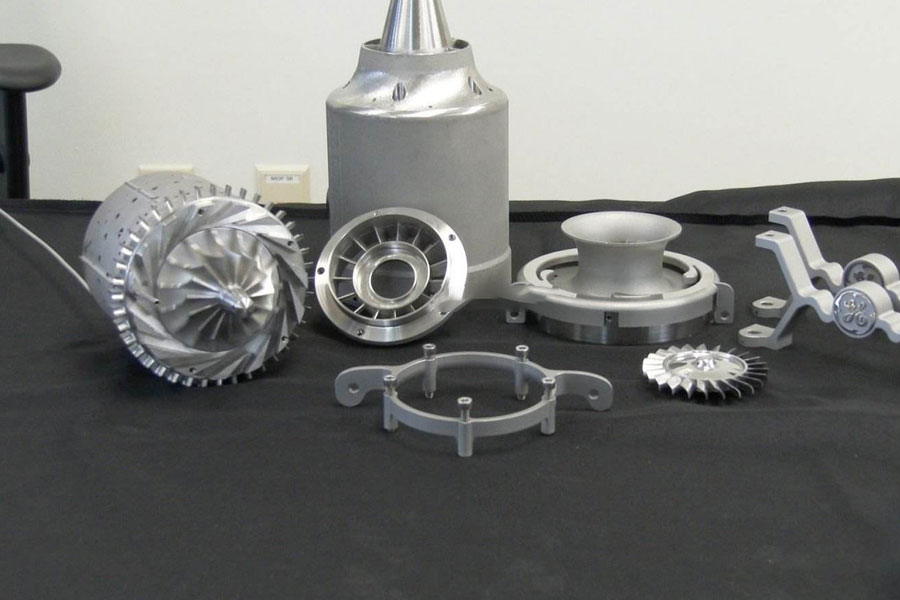

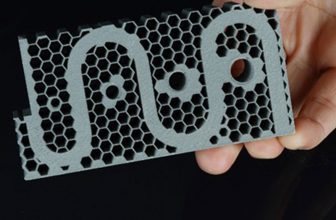

3D Printing Complicated Superalloy Parts

Luminous Sphere (Outdoor Cultural And Creative Works)

PTJ offers online 3D printing services for china rapid prototyping and production of non-metal and metal 3D printed parts at affordable prices.

- * Supports drawing uploads in file formats “.pdf”, “.jpg”, and “.png”.

- * Supports file uploading and loading of 3D (3D) CAD data “.igs” and “.step”.

- * Supports file uploading of two-dimensional (2D) CAD data “.dxf” and “.dwg”.

- PC

- ST-130

- PA 2200

- CoCrMo

- PA 3200 GF

- ABS M30

- Ceramic

- POM-like

- ULTEMTM 9085

- Paraffin Material

- Polyphenylsulfone

- Polyetheretherketone

- Soft Rubber Material

- Aluminum Filled Nylon

- High Ultra-Fine Plastic

- Mold Steel MS1

- NickelAlloy IN718

- Titanium Alloy Ti64

- White Photosensitive Resin

- Black Photosensitive Resin

- Transparent Photosensitive Resin

- Full Color Photosensitive Resin

- Micro-nano Material

- High Ultra-Fine Plastic

- Full-Color Gypsum Composite Material

GET IN TOUCH OR GET A QUOTE

PTJ 3D Printing

Mobile WhatsApp WeChat:

+86 8288 6112

+86 152 1709 1354

Email: [email protected]

Address: Dongguan City, Guangdong Province, China.