Boston Micro Fabrication (BMF), a micro 3D printing system expert, has launched what it calls the “first and only” micro 3D printer microArch S240 for short-term industrial production. The company’s latest printer is modeled on BMF’s patented projection micro-stereolithography technology (PµSL), using other advanced materials, larger printing volume and faster printing speed.

BMF Global CEO John Kawola said: “Until now, industrial production still lacks this coveted combination of quality, strength and resolution, especially for users who need high precision and micron resolution. With the help of microArch S240, the user can finally produce the final-use micro-parts at the required speed. Its resolution, accuracy and precision are equivalent to CAD. For manufacturers and engineers, smaller parts no longer require more trouble and Higher prices.”

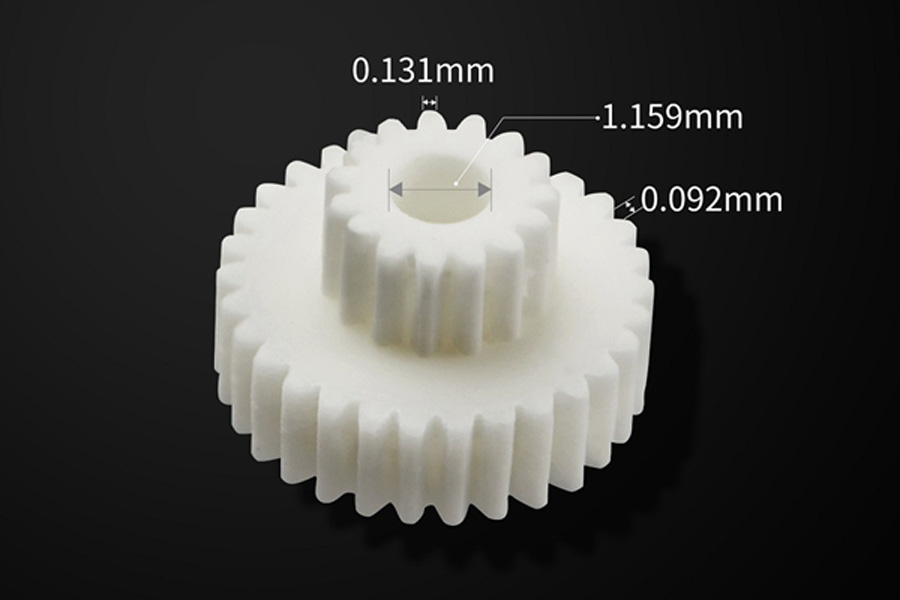

Miniature ceramic gears printed with microArch S240. The picture comes from BMF.

High-precision 3D printing

In February, after BMF launched its system in Asia, it announced that its microArch 3D printer (previously known as nanoArch) was launched and renamed globally. However, BMF is not the only micro-precision 3D printing expert. Several other companies are also making progress in this field.

Nanoscribe, a manufacturer of two-photon 3D printers, offers a system that uses two-photon polymerization technology to produce parts with a resolution as low as 200 nanometers. The German company recently released a new photosensitive resin, which is said to “take the manufacturing of micro-optical components to a new level.”

Elsewhere, Nanofabrica, a Tel Aviv-based developer of precision additive manufacturing technology, commercialized its micron-level resolution 3D printing technology in March last year. Its technology is based on a digital light processing (DLP) engine and adaptive optics (AO), which is used to enhance image distortion in optical devices.

Recently, researchers at Yokohama National University (YNU) designed a new 3D printing method that can use stereolithography (SLA)-based technology to 3D print multi-color microstructures using different materials.

MicroArch S240 micro 3D printing system

BMF’s PµSL technology uses a micron-level resolution UV flash lamp to rapidly photopolymerize the liquid polymer layer to produce delicate and reproducible parts. According to China 3D Printing Network, this technology can print microstructures 100 times smaller than a human hair. It is an ideal choice for terminal components and prototyping in industries such as microfluidics, electronics, medical equipment manufacturing, and biotechnology. The design of microArch S240 is large (100x100x75 mm / 750 cm), which can meet the needs of industrial production, and because of its advanced spreading mechanism, its printing speed is 10 times faster than the previous model. This means that larger or smaller parts can be produced while maintaining the 10 µm resolution and +/- 25 µm tolerance of its other printers.

The microArch S240 can print industrial-grade composite polymers and ceramics, and can also produce more powerful micro-precision parts because it can handle higher molecular weight materials with a viscosity of up to 20,000Cp.

BMF RG 3D printing material

BMF cooperated with chemical expert BASF (BASF) to develop a new functional engineering material for microArch S240, called BMF RG. The material is derived from BASF’s Forward AM Ultracure3D photopolymer resin production line, which has high strength and durability and is suitable for industrial production needs.

“The new BMF RG material from the Forward AM Ultracur3D photopolymer resin production line will enable users to achieve ultra-high resolution of their parts.” said Oleksandra Blacka, BASF’s photopolymer, medical and dental business development manager. “The microArch S240 printer is addressing previously unserved markets. Now, this collaboration will enable customers, especially those in the medical industry, to assemble complex items that are too small to be handled on the previous printing platform.”