The current 3D printing technology has become more and more perfect, and gradually began to integrate into our lives, and suddenly felt that it seems to be everywhere. Unexpectedly, the medical industry can also apply 3D printing, and it has very good results. Let’s see what it looks like.

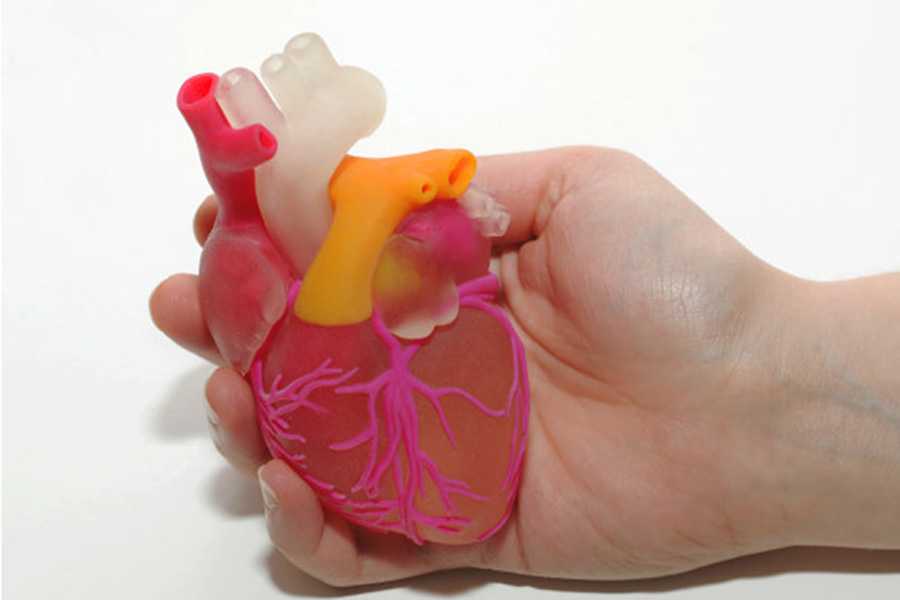

At this stage, the key applications of 3D printing in the medical industry include: 3D printed medical models for surgery and planning or teaching, surgical guides, surgical/oral implants, rehabilitation equipment, and biological 3D printed human tissues and organs. With the upgrading of materials, biocompatible 3D printing materials have also created practical examples for the clinical application of 3D printing blood vessels and organs.

3D printing of medical models and surgical guides

Before the operation, three-dimensional modeling is performed based on the patient’s CT data, and then the model is printed out with a 3D printer to obtain a medical model. The key role of the model is to allow the doctor to directly see the three-dimensional structure of the surgical site before the operation, which is helpful for the doctor to plan the surgical plan. Especially for complex operations, it is helpful to reduce the risk of the operation and improve the success rate of the operation.

3D printing of rehabilitation equipment

The true value of 3D printing for orthopedic insoles, bionic hands, hearing aids and other rehabilitation devices is not only the completion of precise customization, but also the key to the replacement of manual production methods with accurate and efficient digital manufacturing technology to reduce the production cycle. Take hearing aids as an example. In traditional craftsmanship, the technician must make an injection mold based on the patient’s ear canal model, and then perform post-processing such as drilling sound holes on the mold. The use of a 3D printer to make a hearing aid only needs to convert the scanned CAD file into a design file that can be read by the 3D printer, and then print it out. At this stage, large-scale industrial 3D printers on the market can also be used for medical model printing in addition to industrial applications.

3D printing of implants

Bone defects, maxillofacial injuries, and skull repairs caused by bone tumors, car accidents, etc. cannot be treated with general repair products, but 3D printing products provide reasonable and effective solutions. The printed prosthesis can be tailored according to the patient’s own characteristics.

And nowadays, the very common digital oral technology is the use of 3D printing technology for dental treatment. According to the use of digital guides and other places, dental medical care is more accurate, and the problem of shortage of dental medical resources is effectively reduced.

Medicine 3D printing

There are four key impacts of 3D printing technology on manufacturing: complete the personalized customization of active ingredients of the drug; personalized customization of dosage; personalized customization of shape; make the drug have a special microstructure, improve the release behavior of the drug, and improve the efficacy Reduce drug side effects.

Organ 3D printing

A well-known example is that in April 2019, Tel Aviv University in Israel successfully used the patient’s own tissues as raw materials to 3D print the world’s first “complete” heart with cells, blood vessels, ventricles and atria.