In recent years, 3D printers have begun to get rid of the use of plastic filaments, metal powder and other printing fields. They are now also used to print products from edible materials and new ingredients, such as 3D printing meat, 3D printing KFC, 3D printing milk desserts, etc. , Which not only helps to use edible materials to make non-traditional food conveniently, but also brings consumers healthier and more personalized products.

The latest advances in digital manufacturing (especially 3D printing) have allowed the freedom to manufacture 3D structures and equipment using plastics, metals, and other raw materials. So far, 3D printed structures have demonstrated a wide range of applications, including sensing, tissue engineering, and physiological blood vessel modeling. The latest frontier of 3D printing is focused on the direct printing of edible materials. In fact, it is not surprising that 3D printing has had an impact on the chocolate industry. In the past few years, many companies have been experimenting with 3D printing chocolate, and 3D printing has brought creativity and innovation to the industry. It is understood that most chocolate 3D printers use CAD files, just like ordinary 3D printers. The chocolate 3D printer moves through the extruder head and lays the melted chocolate in the desired shape, after which the chocolate cools and becomes solid.

However, chocolate 3D printers are currently not suitable for mass production. The main problem is temperature. The chocolate must be heated enough to melt, while it must be cooled and dried to maintain its shape. If the temperature is not suitable, the 3D printed chocolate will lose its shape due to temperature and gravity. And the process of 3D printing chocolate is very time-consuming, which is caused by temperature. Researchers from Singapore University of Technology and Design (STDU) used Direct Ink Writing (DIW) 3D printers to print chocolate-based ink directly in the liquid phase for the first time, thereby modeling complex 3D shapes without temperature control. Researchers call this method chocolate-based ink 3D printing (Ci3DP).

3D food printing allows the printing of foods with customized nutritional content, and in principle, nutrition can be optimized based on biological characteristics and genomic information. Similar to other 3D printing technologies, 3D food printing relies on layer-by-layer manufacturing based on CAD data and sequential deposition of 2D layers. The food ink can be customized by the coordinated combination of the basic ingredients of the food (such as carbohydrates, proteins, and fats). For 3D food printing, different 3D printing technologies have been demonstrated, selective laser sintering (SLS), inkjet printing, hot melt extrusion and adhesive jetting. Among them, extrusion is the most popular method in 3D food printing. During the extrusion process, materials (liquid, semi-solid, or solid) are passed through a nozzle to create a 3D object. There are three kinds of extrusion technologies: cold, hot melt and gel forming extrusion. Cold extrusion is performed at room temperature without phase change. Hot melt extrusion is mainly based on a mechanism similar to Fused Deposition Modeling (FDM): (1) heating to make the ink flow out of the nozzle; (2) cooling to solidify the molten chocolate in the bed. Gel forming extrusion involves the phase change of the liquid material after extrusion. Extrusion-based technology has limitations in terms of stability and self-supporting properties of printed objects. However, due to its simplicity, extrusion has been used to print different types of food.

Chocolate is a small solid particle composed of sugar and cocoa powder. It is a compound emulsion formed in a continuous fat phase and is a popular food. As a material, chocolate is solid at room temperature (20 to 25°C) and melts in human mouth and saliva (37°C). The melting characteristics and texture of chocolate depend on the type and ratio of cocoa powder and other ingredients, as well as the method of mixing and processing them. The ingredients are mixed, refined and refined during processing to obtain the proper chocolate viscosity before tempering. Chocolate is often used for display of 3D food printing because it can be patterned by hot melt extrusion and become solid at room temperature.

In experiments conducted by previous researchers, the chocolate was melted and distributed at a temperature of 31 to 36°C. Since the rheological properties of molten chocolate are sensitive to temperature, temperature needs to be paid attention to. Hot melt extrusion of chocolate has advantages in simplicity and accessibility, and its printing mechanism also has inherent shortcomings. It needs to be controlled within a narrow operating temperature range, which may have high limitations. And flexibility. The cold extrusion only depends on the rheology of the printing ink at the working temperature, and does not need to control the temperature, and the entire printing can be performed at room temperature. However, due to the lack of inks with proper rheology, no in-depth research has been conducted on 3D modeling of chocolate-based materials through cold extrusion before 2020.

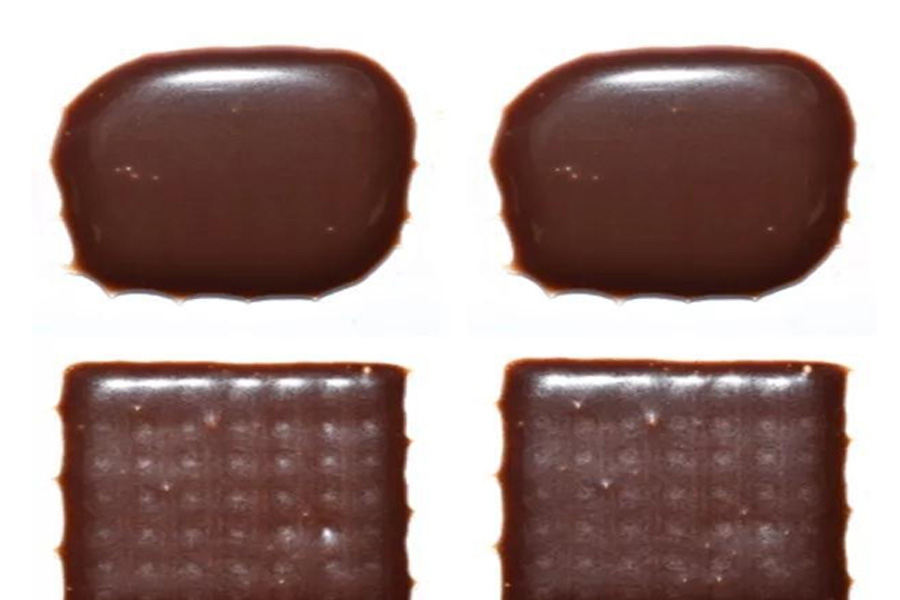

In the Ci3DP method, readily available chocolate products (such as syrup and paste) are mixed with cocoa powder to change the rheology of the ink. Chocolate-based inks with high concentrations of cocoa powder have high-viscosity shear-thinning properties. The ink also has characteristics similar to toothpaste and does not flow when it is stationary.

▲The concept of chocolate-based ink 3D printing (Ci3DP) involves mixing liquid chocolate products with edible additives and printing them with a direct ink writing (DIW) 3D printer at room temperature. The formulated ink can be easily extruded through a syringe and nozzle, and forms a self-supporting layer after extrusion to maintain the printing structure.

The simplicity and flexibility of Ci3DP offers great potential for manufacturing complex chocolate-based products without the need for temperature control. To further demonstrate the flexibility of this method, the same method was extended to produce chocolates with different textures by using multiple types of inks. A piece of chocolate can be made with a semi-solid shell and filled with liquid at the same time.

Multi-material food:

- (A) Schematic diagram of the steps involved in DIW of various food materials at room temperature. The sequence of steps allows the printing of chocolates with internal fillings.

- (B) The 3D structure of a cone-shaped shell containing liquid chocolate syrup as a filling.

- (C) Highlight the optical image of the liquid chocolate syrup flowing from the 3D printed shell. Scale bar = 1 cm.

Ci3DP can use a variety of materials to make customized foods with customized textures and optimized nutrients. This new method also expands the industry’s capabilities in 3D food printing, cold extrusion of temperature-sensitive food.