Customers often ask whether the printing accuracy of SLA can reach 0.05 mm?

Simply answer, according to the current situation of SLA equipment on the market (2020), the printing accuracy of 0.05mm cannot be achieved stably. Some merchants in the market say that the printing accuracy of their SLA is 0.05mm, even if it is not a deceitful trick, at least it is A digital game that steals the concept.

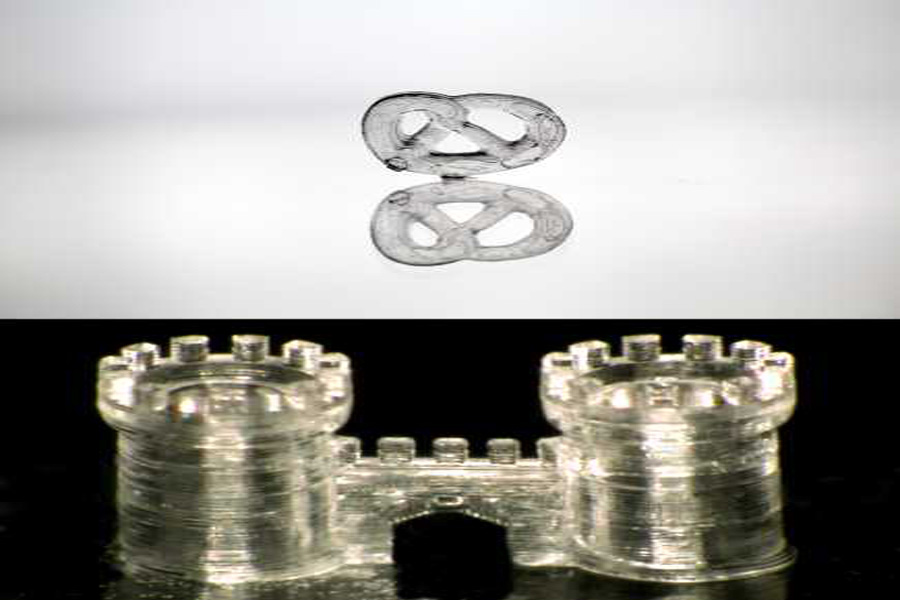

3D printing problem ideas

First of all, let’s take a look at the accuracy of the SLA equipment manual. If the printed item is within 100mm, the accuracy is ±0.1mm. If the printed item exceeds 100mm, the accuracy is 0.1%. We can see that the accuracy of the SLA equipment starts from 0.1mm, which can be considered as a system. The error is at least 0.1mm.

So what are the factors that affect the accuracy of SLA 3D printing? Is it possible to simply use the layer thickness to represent the printing accuracy? https://3d-printing-china.com/will take care of it for everyone today to see what factors affect the 3D printing of SLA photosensitive resin.

Layer thickness (LAYER THICKNESS)

This may be the most confusing factor with printing accuracy at present, but printing layer thickness≠printing accuracy

The printing layer thickness has a certain relationship with the accuracy. Generally speaking, the printing layer thickness is small, and the printing accuracy will be higher in the Z direction. The layer pattern on the surface is more delicate and the accuracy is higher intuitively. This may be the result of many people printing The layer thickness is regarded as the direct cause of printing accuracy.

In fact, the printing layer thickness is not as low as possible. The printing layer thickness is less than 0.1mm, which has almost no effect on the improvement of printing accuracy. The system error of 0.1mm will swallow this difference, but it will bring longer printing. Over time, the burden on the motor has increased exponentially, the probability of abrasion and damage to the printing squeegee increases greatly (used to smooth the printing surface after printing a layer), and the probability of printing failure increases.

In short, the increase of the printing layer thickness will make the outer surface more delicate, but it will not help the printing dimensional accuracy. On the contrary, it will increase the probability of printing failure and decrease the printing efficiency.

Spot diameter (SPOT DIAMETER)

The diameter of the SLA spot is similar to the diameter of the nozzle of the FDM device. Generally speaking, the smaller the spot diameter, the higher the printing accuracy, but not the finer the better. The spot diameter of the SLA device is generally above 0.1 mm, and the same layer thickness is similar. Less than 0.1mm is of little significance, on the contrary, it increases the burden on the system and reduces the efficiency and success rate.

The performance of printing materials (MATERIAL PROPERTIES)

The curing of SLA printing raw material resin is a chemical reaction. During the chemical reaction, small molecular chains will combine to become large molecular chains. The molecular chains will have a relaxation process. Even after printing is completed, there will be a period of time to rebalance inside the molecules. , That is, the printing accuracy may change with the printing completion time. Just print out a precision, one day, three days, and half a month later, the accuracy may change to a certain extent-dimensional stability, which is a lot of materials The difference, the score said imported photosensitive resin and domestic photosensitive resin.

SLICING AND SUPPORT SETTINGS

In the process of SLA printing, it is inevitable that support will be added to the print target to support the overhanging structure. Whether the support is reasonable, sufficient, or appropriate may affect the accuracy of the print target.

3D printing accuracy is affected by support

PRINT ORIENTATION Different placement directions may have different accuracy. For example, if you print a ⚪, if ⚪ visits on a surface parallel to the XY plane, the accuracy of ⚪ will be higher. If ⚪ is placed on a plane perpendicular to the XY plane, The accuracy may be worse.

Environmental temperature and humidity (ENVIORMENTAL TEMPERATURE AND HUMIDITY)

SLA printing requires a constant temperature and humidity environment, and temperature and humidity fluctuations should be controlled to a minimum. Any large fluctuations may cause changes in accuracy.

The mechanical status of the equipment (MECHNICAL STATUS) SLA is a high-precision equipment with highly sensitive accuracy. If used improperly, problems with mechanical movement will affect the accuracy. The movement accuracy of the printing platform and the guide rail is theoretically high, but the machine is not in good condition, and there will be serious accuracy problems if it is not maintained and calibrated in time.

POST PROCESSING

After the SLA is printed, it is inevitable that there will be post-processing, including alcohol cleaning, sandblasting, de-supporting, polishing and so on. These mechanical or manual processes may affect accuracy.

3D file format conversion (3D FILE FORMAT CONVERSION)

There are various types of 3D files, including solid modeling and surface modeling. In the process of converting the format into a 3D printable format, there may also be accuracy deviations. Generally, this deviation will be less than the printing accuracy, but in a certain In some cases, it may also have a greater impact on accuracy.

To sum up, there are many factors that affect the accuracy of SLA 3D printing. The printing accuracy cannot be expressed by layer thickness alone. The current mainstream SLA equipment guide accuracy of 0.1mm is due to system reasons. Individual merchants on the market use 0.05mm printing layer thickness. Replacing the printing accuracy is actually a stealth concept, a digital game, a marketing gimmick, and it does not mean that there can be a stable output of 0.05mm accuracy.

As a responsible professional 3D printing service organization, 3d-printing-china.com can provide a relatively stable 0.07mm precision output. If there are customers in need, you can also contact our customer service.