Metal 3D printing is considered the culmination of all 3D printing. When it comes to strength and durability, nothing can compare to metal. The earliest metal 3D printing patent was DMLS (Direct Metal Laser Sintering), which was obtained by the German EOS in the 1990s. Since then, metal 3D printing has gradually developed many types of printing processes. Now, every metal 3D printer usually uses one of the following four types of processes: powder bed fusion, binder injection, direct energy deposition, and material extrusion.

Metal Powder Bed Fusion

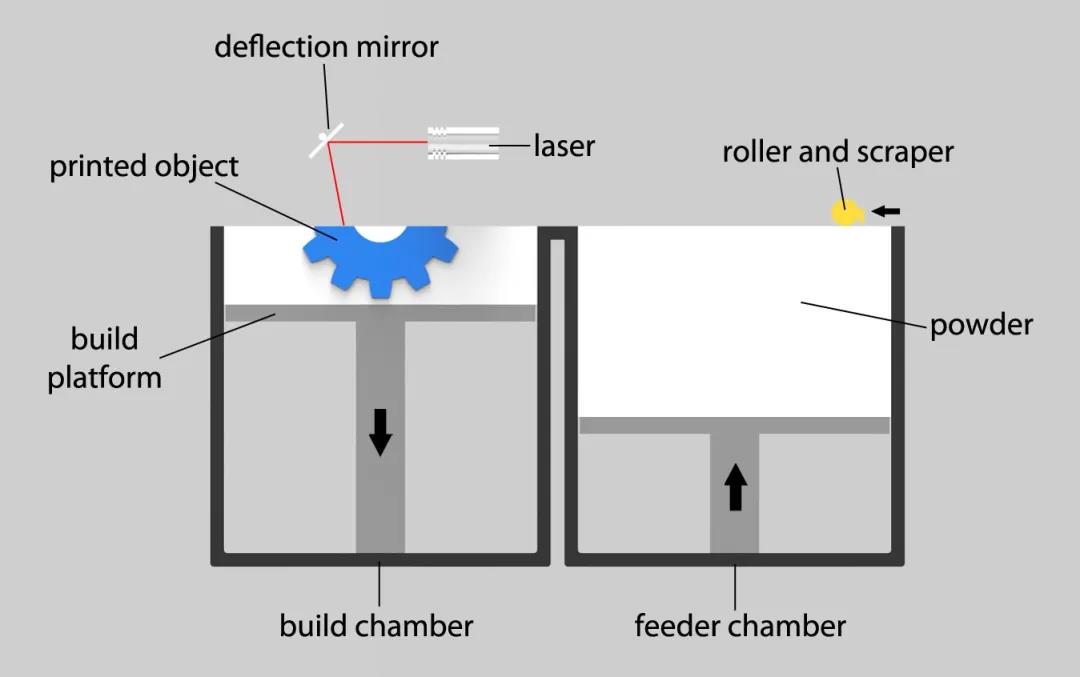

pbf

Common processes: DMLS (direct metal laser sintering), SLM (selective laser melting) and EBM (electron beam melting).

Description: Metal parts produced using PBF melting technology can reduce residual stress and internal defects, making them ideal for demanding applications in the aerospace and automotive industries.

Direct metal laser sintering (DMLS): It can be used to build objects with almost any metal alloy. Direct metal laser sintering spreads a very thin layer of metal powder on the surface to be printed. The laser slowly and steadily traverses the surface to sinter this powder, and the internal particles of the metal fuse together, even if they are not heated to a completely molten state. An additional layer of powder is then applied and sintered to “print” one cross-section of the object at a time. After printing, the object will slowly cool down, and the excess powder can be recovered from the build chamber and recycled. The main advantage of DMLS is that the objects it produces have no residual stress and internal defects, which is extremely important for metal parts under high stress (such as aerospace or automotive parts), but the main disadvantage is that it is very expensive.

Selective laser melting (SLM): Use a high-power laser to completely melt each layer of metal powder, not just sintering, so that the printed object produced is very dense and strong. Currently, this process can only be used for certain metals, such as stainless steel, tool steel, titanium, cobalt-chromium alloys, and aluminum. The high temperature gradient that occurs during the SLM manufacturing process can also cause stress and dislocation in the final product, which will damage the physical properties.

Electron beam melting (EBM): It is very similar to selective laser melting and can generate dense metal structures. The difference between these two technologies is that EBM uses an electron beam instead of a laser to melt metal powder. Currently, electron beam melting can only be used for a limited number of metals. Although cobalt-chromium alloys can also be used, titanium alloys are still the main raw material for this process. This technology is mainly used to manufacture parts for the aerospace industry.

Technical advantages: Almost any geometric shape can be manufactured with high precision. A wide range of metals are used, including the lightest titanium alloy and the strongest nickel superalloy, which are difficult to process with traditional manufacturing techniques. The mechanical properties can be comparable to forged metals, and can be machined, coated and treated like traditional metal parts.

Technical disadvantages: high material, mechanical and operating costs. The parts must be connected to the build plate through a support structure (to prevent warping), which generates waste and requires manual post-processing and removal. The build size is limited, and metal powder handling is dangerous, requiring strict process control.

Metal Binder Jetting

Metal Binder Jetting

Commonly used processes: MJF (multi jet fusion), NPJ (nano particle jet)

Description: This technology uses inkjet to selectively drop a binder onto a flat powder bed. The area receiving the droplets will be solidified, and the rest of the powder will remain loose. Perform the above steps layer by layer until the entire object is generated. This process can be used to process metals, sand, ceramics and other materials. Since the metal adhesive spraying machine operates at room temperature, there is no warpage and no support is required. Therefore, the binder spraying machine can be much larger than the powder bed fusion machine, and can stack objects, make full use of the entire build room, and is a popular choice for small batch production and on-demand manufacturing.

Technical advantages: large volume printing is possible, parts do not need to be connected to the build plate, so they can be nested to utilize all available build volume. There are few restrictions on the geometry and usually no support is needed. There is no warpage, so larger parts can be made. The printing speed is very fast, and the cost is lower than powder bed molten metal printing.

Technical disadvantages: parts must go through time-consuming degreasing and furnace sintering processes after printing, and the cost of machinery and materials is high. The porosity is higher than the powder bed fusion, so the mechanical properties are not so good, and there are fewer materials to choose from.