The additive manufacturing department of Japan’s Yamaichi Special Steel has redesigned the brake caliper. The manufacturing process used in the redesigned brake caliper is selected area laser melting 3D printing technology.

The additive manufacturing process releases design freedom. The redesigned brake caliper can integrate heat exchange structure on the basis of achieving weight reduction and increase The oil supply direction of the pressure oil circuit. This design case has certain reference significance for design optimization and innovation of automotive safety components.

Realize weight reduction and function integration in a limited space

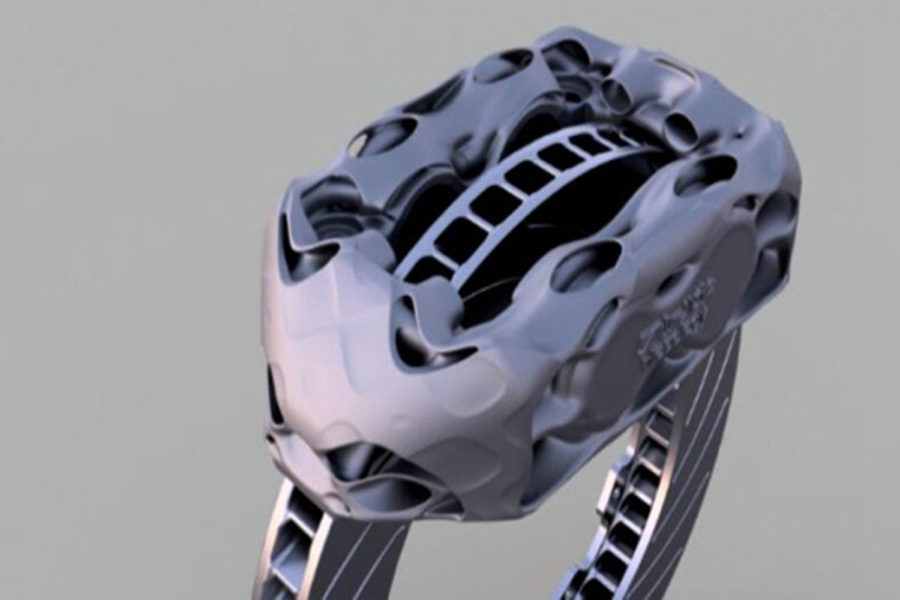

YAMAICHI applied topology optimization technology in the redesign and integrated the TPMS structure for additive manufacturing in the brake caliper. In addition, YAMAICHI has added an optimized pressure loss oil circuit to the design. Considering that the brake caliper may encounter environmental factors such as gravel impact when working, YAMAICHI has added a protective surface under the brake caliper to prevent impact damage.

TPMS is a triple periodic minimum surface (TPMS). For structural applications, the design shows a high strength-to-weight ratio. This design, if used in conjunction with additive manufacturing technology, will enable designers to create multifunctional structures with high strength and heat dissipation characteristics.

According to the design scheme disclosed by YAMAICHI, they did design a brake caliper with integrated heat exchange structure. The function of the heat exchange structure is to cool the brake caliper during the braking cycle, and the air flow can pass through the cooling vent and Speed up the cooling process. The brake caliper with this design is 40% lighter than the traditional design.

Another design innovation of this brake caliper is the pressure oil circuit. Normally, there is only one direction in the pressure oil circuit to supply oil to the caliper piston, but after the design is optimized, there are five directions to supply oil to the caliper piston. This design helps to produce a better pressure distribution on the piston surface.

Metal 3D printing technology is mostly used to manufacture complex structural parts, but its use to manufacture safety parts such as brake calipers is an area of doubt. However, the 3D printed titanium brake calipers developed by sports car manufacturer Bugatti and its partners for the Chiron sports car have made a strong response to these doubts.

Chiron is currently one of the most powerful and fastest supercars. It has excellent acceleration performance. It requires no more than 42 seconds to accelerate from 0 to 375 km/h and decelerate to 80 km/h. The excellent performance is essential for lightweight and The powerful engine puts forward extremely high requirements, and also puts forward higher requirements on the performance of the brake system.

The 3D printed titanium alloy brake calipers developed by Bugatti and its partners have achieved a good combination of weight reduction, performance and strength. The 3D printed titanium alloy brake caliper is 41 cm long, 21 cm wide, 13.6 cm high, and weighs only 2.9 kg. Compared with the previously used aluminum parts weighing 4.9 kg, Bugatti can ensure higher strength by using new titanium alloy parts and reduce the weight of the brake caliper by about 40%.

Bugatti has tested the performance of this new 3D printed eight-piston monolithic brake caliper. The 3D printed titanium alloy brake caliper can meet extreme strength, stiffness and temperature requirements at a speed of 375 km/h, with a braking force of 1.35g and a brake disc temperature as high as 1,100°C. The tensile strength of the 3D printed brake caliper is 1250 N/mm2, and the material density exceeds 99.7%. Performance testing further reveals the industrialization prospects of this innovation.