With the advent of a new era of commercial space flight, the National Aeronautics and Space Administration (NASA) and private space companies are rushing to land on the moon and Mars for space tourism and exploration. Although this is a carefully planned plan to land astronauts on the South Pole of the Moon by 2024 and deploy a manned ground lander on the Red Planet by 2030, we have not gotten from our nearest neighbor, Earth. Much has been learned from sister planet Venus.

Despite many differences from Earth, the hot conditions on Venus used to be like those on Earth. Although no lander has ventured into the surface of Venus since the 1980s, NASA’s re-emergence of Venus could lead to a potential flagship mission to understand whether our sister planet is habitable.

In the future, to successfully explore the extreme environment on the surface of Venus (the thick atmosphere traps the sun’s heat, causing the surface temperature to exceed 880 degrees Fahrenheit (470 degrees Celsius)), complex electronic systems that can operate at high temperatures will be required. Fortunately, creating extreme environmental technology is a top priority for Ozark Integrated Circuits, which is committed to producing novel circuits for “rugged” applications. The Arkansas-based company was recently selected by the National Aeronautics and Space Administration (NASA) as one of 139 companies to provide follow-up funding through the agency’s Small Business Innovation Research (SBIR) program, which aims to develop high-temperature applications. , Prototype multi-chip packaging system for high-density electronic products.

In addition, Ozark will collaborate with nScrypt’s research department Sciperio and nScrypt 3D manufacturing system to create high-temperature electronic systems, especially RISC-V processors, which can run on the surface of Venus for a long time. The company’s “Extreme Environment System Integration Technology for Venus Field Processing” proposal aims to create a 500⁰CRISC-V multi-chip system in package form to illustrate design procedures, multi-chip packaging and high-temperature components. Establish a high-temperature electronic system.

The 500⁰CRISC-V microprocessor is the basic calculation basis for almost all space exploration functions (such as actuation, environment sensing and robot movement) on the surface of Venus. However, in rockets and other potential non-NASA applications (such as jet engine control systems), high-temperature environments where this computing component can be used have also been found. Hypersonic engines for flight and weapons; geothermal exploration (its environment is very similar to the surface of Venus); scientific experiments, including volcano analysis and control and monitoring of production furnaces.

Ozark founder and CEO Matt Francis said: “Additive manufacturing is the cornerstone of Ozark IC’s response to high temperatures. Our adoption and adaptation of AM, especially nScrypt products, will change the rules of the game. With AM’s common lower cost and Fast turnaround indicators have achieved impressive performance (up to 800⁰C). The unique quality and versatility of the nScrypt system enable Ozark IC to develop new processes and products, and achieve amazing results in performance and turnaround time. “

This work was initially funded by NASA’s SBIR Phase 1 project and will continue in the Phase 2 project announced in early May. All second-stage proposals are selected based on their technical advantages and feasibility, the results of the first stage, and the experience, qualifications and facilities of the submitting organization.

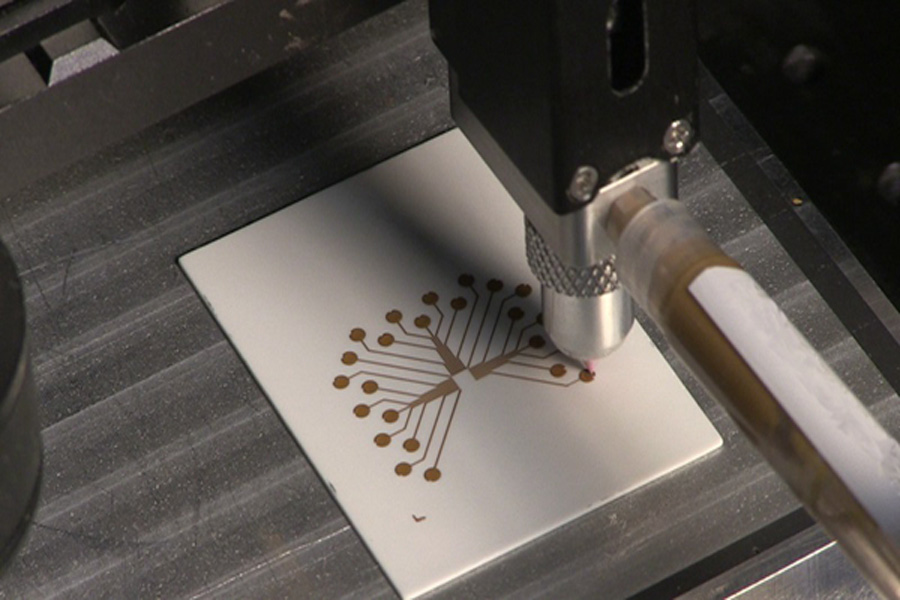

Ozark worked closely with Sciperio in the first phase of the project to print customized 3D printed high-temperature metal traces onto high-temperature substrates. According to the company, these test specimens were printed on the Sciperio site using the nScrypt 3Dn 450 factory in a tool (FiT) system equipped with a SmartPump micro-dispensing tool head, a Keyence laser and a camera in the process to monitor the line Broad and other characteristics. nScrypt’s FiT system is not limited to 3D printing, it can also manufacture finished products, not just parts.

Ozark even stated that it will purchase its own 3Dn-Tabletop system developed by nScrypt, which is also equipped with a SmartPump tool head and a surface mapping laser for conformal printing. Ozark’s expertise is to integrate integrated circuits, packaging and wiring into a module that can be used in harsh environments, and high-temperature multi-chip packaging and Ozark’s design tools significantly expand the complexity of electronic systems that can operate at high temperatures. Ken Church, CEO of nScrypt and Sciperio, said: “Ozark IC has done a great job in extreme temperature electronics. Our high-precision 3D manufacturing system is very suitable for its application, and the engineering expertise of Sciperio, the research department of nScrypt, is helping them to leapfrog. The finish line.”

The second phase of the awards will provide approximately $104 million in awards to 124 small businesses located in 31 states. Every year, NASA invests in small businesses in the United States through promising new technologies that can benefit space missions and improve life on Earth.

“Small companies provide innovative solutions that benefit all areas of NASA, and they often find applications outside the agency.” said Jim Reuter, deputy director of NASA’s Washington Space Technology Mission Agency. “This announcement is NASA’s “Moon-to-Mars” exploration method. Another step. The agency will continue to invest in and support small businesses because they will continue to develop important technologies for future missions that can also benefit us on the planet.”

When announcing the companies selected for the second phase of the 2019 SBIR program in May last year, NASA pointed out that these awards will help advance NASA’s priorities, including the Artemis program and other initiatives in the fields of aviation, human exploration and operations, science and space. technology. The selected companies are previous NASA SBIR Phase 1 winners, and they have successfully established the feasibility of their proposed technology. As the winners of the second phase, these companies will develop, demonstrate and deliver their technology to NASA.

NASA SBIR program executive officer Jenn Gustetic said: “We are encouraged by the creativity and creativity that these companies have seen in the first phase of their work. We are also working to reduce the amount of time that selected companies wait for their first phase II payment. Time, because we know the key to obtaining funding for our aerospace research and development company. Their technology has broad application prospects inside and outside NASA, and we look forward to the next round of accelerating the use of seed funding.”

Ozark has used SBIR/STTR funds to develop its technology. At present, its other product lines have operating temperatures of 200⁰C and 250⁰C, respectively, and are entering the manufacturing phase (Phase 3).

Comment: Due to the amazing atmospheric pressure and the rising temperature, up to 900 degrees Fahrenheit, Venus is not the easiest place to detect and explore. After just a few hours, the electronic equipment of the spacecraft began to fail, so the life of any landing mission would be shortened. In fact, exploration missions from the United States and Russia in the 1970s could transmit data for up to an hour after reaching the surface of Venus. In 2006, the European Space Agency’s Venus Express discovered strange atmospheric features at the south pole of Venus and discovered clouds that extend 100 kilometers above the ground.

Space exploration requires complex electronic systems that can operate under high temperatures and a rocky mantle, especially when NASA’s interest in Venus is renewed. Unlike Venus and the Earth’s environment, many experts believe that data from the planet can help us understand our own atmosphere, and as Ozark prepares to develop a prototype multi-chip package for high-temperature, high-density electronic systems, the duration is long, and Venus’s Close exploration may become a reality.