The outbreak of the new crown pneumonia in early 2020 shows that today’s supply chains between global manufacturers and their customers are vulnerable to external risks. It is understood that nearly 75% of supply chain executives have reported major supply chain disruptions in 2020 due to Covid-19, and nearly half of them reported that they have not developed a backup plan to deal with such supply chain disruptions.

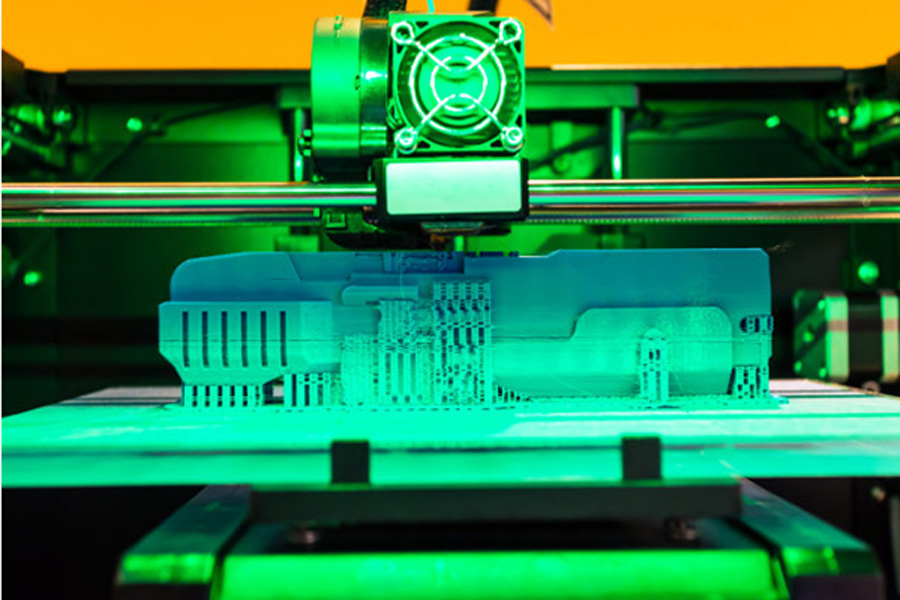

Based on this, how will the problems caused by the disruption of major global supply chains be solved? One of the solutions is to integrate 3D printing into manufacturing operations to increase localized production, thereby enhancing the flexibility and flexibility of the supply chain. Despite these benefits, manufacturers are still skeptical. Based on a 2017 survey of manufacturing decision makers, although 81% of companies use 3D printing technology, only 29% of companies use it to produce parts.

If 3D printing can bring so many benefits to its supply chain, why are many manufacturers still reluctant to fully adopt the technology?

Early impressions of expensive and slow 3D printing

The Covid-19 pandemic and the accompanying economic crisis have made 3D printing the focus of attention. From industry leaders to self-operated small businesses, 3D printing is being used to rapidly produce equipment to fight epidemics, such as masks, ventilators, and nasal swabs. Many people think that this may be a turning point for 3D printing, because the technology can help fight the global pandemic, but others still believe that 3D printing is a slow and expensive manufacturing method.

It is unfair and inaccurate to describe the entire industry from this perspective. Facts need to be used to change the impression of 3D printing in the early days.

Metal 3D printing illustrates the tension between vision and reality, especially because of its huge manufacturing potential. Currently, there are several mainstream technologies for metal 3D printing, but so far, the main technologies used by manufacturers are powder-based technologies, such as powder bed fusion and adhesive jetting. These technologies use metal powders fused together to make parts. Metal powder is expensive and dangerous to handle, which means that the production team needs to take other safety measures. Post-processing steps such as powder removal, heat treatment, and machining also increase man-hours and increase costs.

Technology is not ready to reach the golden age

Ten years ago, everyone thought that 3D printing was on the cusp of the “3D revolution.” Unfortunately, the technology at the time could not meet these forecasts, and in many ways, the industry is still struggling to bounce back from falsely high expectations. Manufacturers who became early adopters of 3D printing technology in the first “hype cycle” were “pitted” by immature technology, which made them hesitate to use 3D printing technology again.

How does 3D printing really gain a foothold in the manufacturing industry?

In order to have an impact on manufacturing beyond prototypes, the 3D printing industry needs to do a few things:

Reduce costs and increase speed, eliminating the early impression that 3D printing is expensive and slow.

When it comes to metal 3D printing, this will become the focus of manufacturing. We must find safer alternatives to replace expensive metal powders, such as liquid metal. Only by reducing post-processing, shortening the production cycle and reducing costs can the technology be more attractive to manufacturers and more important for the development of its own industry.

Access to a global service network that is easy to deploy.

Large companies in the automotive, aerospace, and heavy machinery industries will benefit greatly from integrating 3D printing into their supply chains. However, if the machine encounters a problem, and they are not used to relying on small providers to meet their big needs, they cannot afford long downtime. They will expect to get the same strong service level from well-known manufacturers in other business areas.

Learn from the past.

Most manufacturers do not want to completely change their production lines and supply chains through the “3D revolution.” Instead, they are looking for technical solutions to make their current operations more efficient. The 3D printing industry should focus on how to best integrate 3D printing solutions into the existing workflow and supply chain requirements of manufacturers, rather than promoting a revolution, which is not yet in place.

In addition to supply chain benefits, 3D printing can also enable manufacturers to reduce carbon emissions by using materials more efficiently and reducing the transportation costs of finished products. Since sustainability has become a top concern for many companies, this may be another driving factor for increased adoption of this technology.

Looking to the future, the 3D printing industry has a huge opportunity to gain a permanent foothold in the manufacturing field. By proving that 3D printing can become a trusted partner for enhancing supply chain capabilities, 3D printing manufacturers will be in a good position to continue to develop new technologies and materials, and build confidence in future possibilities.