CLIP Process-Polyurethane (PU) materials are made using CLIP process. CLIP is a photochemical process developed by Carbon, which can carefully balance light and oxygen to quickly produce parts. Its working principle is to project light into a container of ultraviolet curable resin through an oxygen-permeable window.

With the projection of a series of UV images, the parts are cured, the construction platform rises, and the 3D printing process is gradually completed. The finished product of the CLIP process can be comparable to the finished product of injection-molded plastic. Regardless of the mechanical properties and appearance details of the material, it is a new generation of 3D printing process.

Polyurethane, IUPAC abbreviated as PUR, generally abbreviated as PU, refers to a type of polymer containing carbamate characteristic units in the main chain. The main characteristics include: oil resistance, abrasion resistance, low temperature resistance, aging resistance, high hardness, and elasticity; this polymer material is widely used in adhesives, coatings, low-speed tires, gaskets, car mats and other industrial fields. Polyurethane PU 3D printing is achieved through the CLIP process developed by Carbon. The quality of the finished product is close to the performance of injection molded products in all aspects, resulting in consistent and predictable mechanical properties. The appearance is smooth, and the interior is firm, which is obviously the same as the performance of general 3D printed products. the difference. Polyurethane PU 3D printing materials are composite polyurethane materials made on the basis of photosensitive resin liquid materials. According to different material properties, they can be divided into the following three types:

RPU-Rigid Polyurethane

Rigid polyurethane or RPU130 is very hard and strong, and its material properties are better than ABS plastics and comparable to nylon. This material is very suitable for mechanical parts that require sturdiness, heat resistance and wear resistance. This material has passed the UL94HB flammability level certification, and the safety of use is further guaranteed.

EPU -Elastic Polyurethane

Elastic polyurethane, or EPU40, is a high-performance polyurethane elastomer, showing a kind of rubber-like appearance. It exhibits excellent elasticity under cyclic tensile and compressive loads, and is elastic in a wide temperature range. EPU can be used in demanding applications requiring high elasticity, impact resistance and tear resistance, such as cushions, gaskets, grommets and flexible watertight seals. Suitable for industries such as automotive, medical and consumer electronics.

FPU-Flexible Polyurethane

Tough polyurethane or FPU50 resin is a semi-rigid material with good impact resistance, abrasion resistance and fatigue resistance. This material is suitable for withstanding repeated stresses such as hinge mechanisms and friction fits.

Polyurethane CLIP 3D printing material FPU

Mechanical performance table:

| Rigid Polyurethane (RPU) | Elastic Polyurethane (EPU) | Flexible Polyurethane (FPU) | |

| Elongation | 100% | 300% | 200% |

| Tensile modulus | 1000 MPa | 8 | 700 MPa |

| Yield Strength | 25 MPa | – | 15 MPa |

| Tensile Strength | 35 MPa | 9 | 25 MPa |

| Flexural modulus | 900 MPa | – | 800 MPa |

| Impact strength | >30 kJ/m | – | 40 kJ/m |

| Heat distortion temperature | 120 | – | 70 |

| Shear strength | – | 20-26 kN/m | |

| Shore hardness | 77 | 64-68 | 71 |

Design requirements:

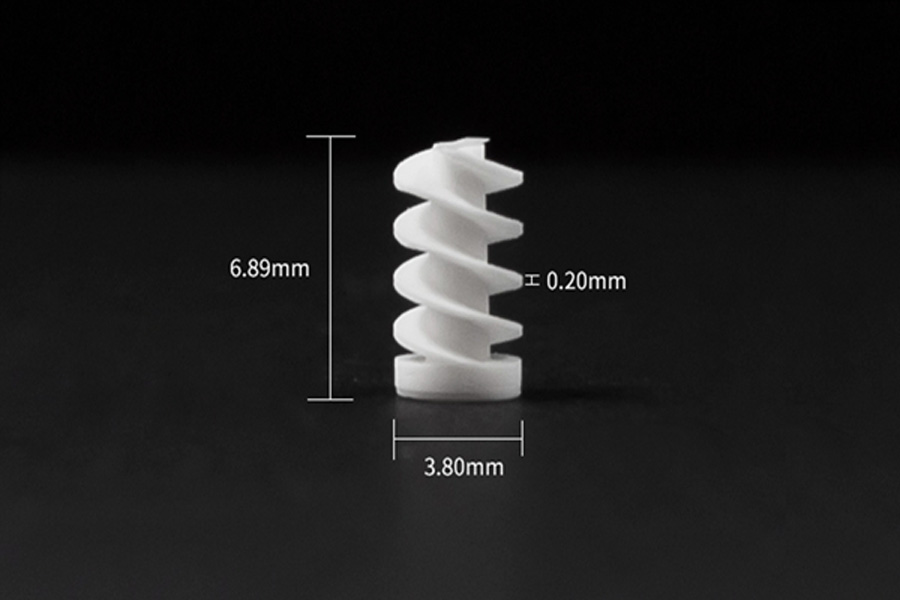

- Maximum printing size: 180 x 110 x 290 (z) mm

- Standard layer thickness (default): 0.1 mm

- Accuracy: (XY) ±0.1 (Z) ±0.4

- Minimum wall thickness: 1mm (with support) or 2mm (without support)

- The smallest detail: 0.4mm

- Minimum gap: 0.4 mm

- Whether it can be hollow: No

- No internal buckle and internal lock structure

- A file contains multiple part entities and needs to be split