According to foreign media reports, for a while, I believe everyone has heard that stent-like implants can promote bone tissue or cartilage to re-grow to the missing part. Now, scientists have developed a way to print such implants with faster and easier 3D printing technology.

First of all, how does the so-called “mini scaffolding” work? If the patient is missing a bone (due to an accident or disease), the doctor will first make an implant, and then place it in the place where the bone should be missing through surgery. The implant has a three-dimensional microstructure similar to a stent and is made of biocompatible, biodegradable materials. In addition, it may contain compounds that promote cell growth.

Since the internal structure of the implant is similar to natural bone, the cells of the adjacent bone tissue of the patient gradually begin to migrate into the implant, “dwelling” in the gap connected to it. These cells continue to multiply and replace the scaffold material. In the end, what is left is pure natural bones to fill the previous gap.

However, 3D printing implants is very tricky, because the walls of the blank areas are very thin and complicated-the printing nozzles on the most commonly used 3D printers simply cannot achieve that detail. This is becoming the entry point for new technologies.

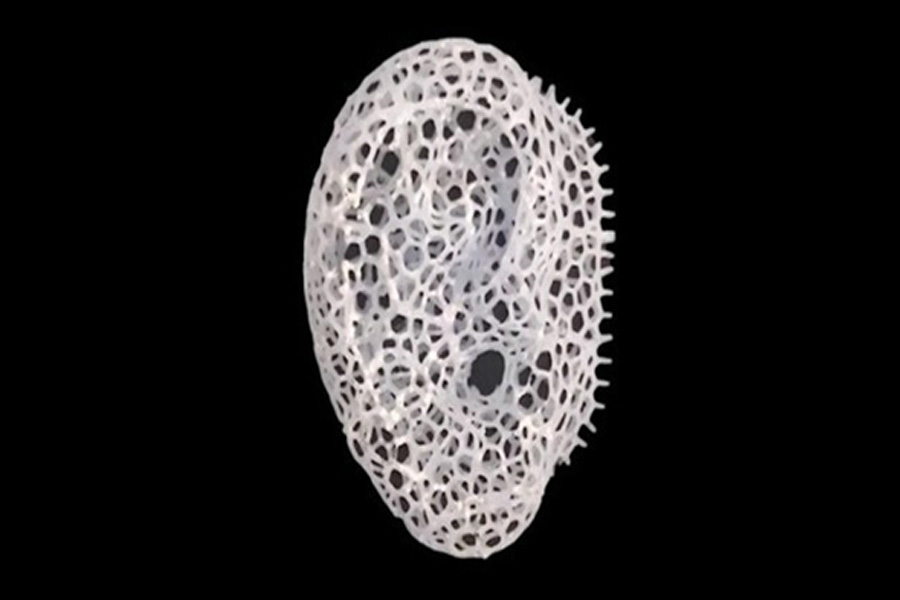

This printing technology is called NEST3D (full name Negative Embodied Sacrificial Template 3D) printing and is jointly developed by scientists from RMIT University in Australia and St. Vincent’s Hospital in Melbourne. The process first prints out the negative template of the blank space of the scaffold through 3D printing, which is made of solid polyvinyl acetate (PVA) glue. An ordinary printer nozzle can do this perfectly.

After the template is placed in the mold, a biocompatible/biodegradable liquid material such as a polymer is poured to fill the unoccupied space of the template. Once the polymer solidifies, water is used to dissolve the soluble PVA glue. In the end, the template disappears, and what remains is the complex polymer “skeleton” that forms the scaffolding.

In addition to playing a role in repairing bone defects, this technology can also be used in applications such as implanting and replacing body parts in the laboratory. “Using an ordinary mid-to-high-end 3D printer to create such complex shapes is amazing. This really lowers the barriers to entry into the field and brings us one step closer to tissue engineering becoming a medical reality,” Chief Scientist, RMIT Said Dr. Cathal O’Connell. “