3D printing, also known as additive manufacturing technology, is a method of constructing three-dimensional objects based on three-dimensional CAD model files, using powder, filament, or sheet materials to construct three-dimensional objects through “layered manufacturing and layer-by-layer stacking”. technology.

The currently widely used 3D printing molding processes mainly include:

Selective LaserSintering, SLS

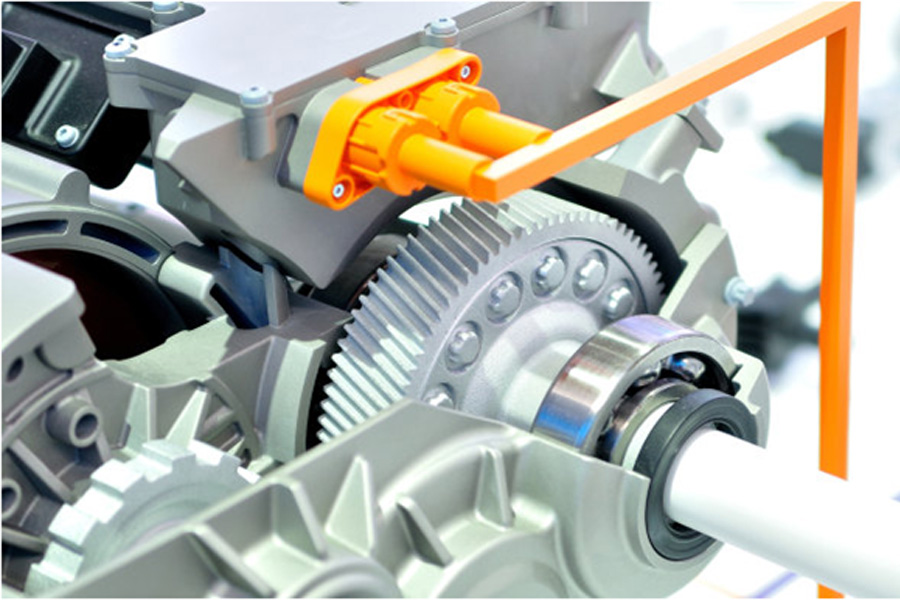

Selective Laser Melting, SLM

Direct metal Laser Sintering, DMLS

Stereo Lithography Apparatus, SLA

Fused Deposition Modeling, FDM

LaminatedObject Manufacturing, LOM, etc.

Different types of processes have advantages in different fields. The application of 3D printing technology in the mold industry is mainly divided into three aspects:

- Make a prototype directly

The above-mentioned 3D printing processes can produce prototypes, but the precision, strength and surface quality of the produced prototypes are different. This is also the most common application method of 3D printing technology at present.

- Indirect manufacturing of molds

That is, using 3D printed prototypes, molds are rebuilt through different process methods, such as silicone molds, plaster molds, resin molds, sand molds, etc.

- Direct manufacturing of molds

That is to use 3D printing processes such as SLS and SLM to directly manufacture soft molds or hard molds

The advantages of 3D printing technology:

(1) 3D printing technology can achieve “zero” waste of production materials in the production process. The production process of 3D printing technology is to print layer by layer according to the three-dimensional design of the parts. Compared with the traditional “subtractive” processing, it achieves “zero” waste of production materials.

(2) The use of 3D printing technology can speed up the progress of product research and development. 3D printing technology has changed the way designers think, they will think according to the different parts of the load-bearing and force-bearing parts.

(3) The use of 3D printing technology can greatly shorten the production cycle. From design to production, 3D printing technology eliminates the process of process design and verification in the traditional processing process, shortens the production cycle, and can adjust the production batch in time according to market demand.

(4) The use of 3D printing technology can greatly reduce the human resources in the design and production process.

(5) 3D printing technology can be used to manufacture molds with special structures, such as conformal cooling molds. This is difficult to achieve with traditional manufacturing methods, and it is also a highlight of the application of 3D printing technology in the mold industry. The conformal cooling mold has many advantages, which can improve the cooling efficiency of the mold, make the cooling of the product tend to be uniform, and improve the product quality and production efficiency.

Comparison of traditional mold and 3D printing mold process

Traditional mold manufacturing process:

The traditional mold manufacturing process is to review the order items after receiving the order, formulate the production schedule after the review, and then perform 3D software revision, mold flow analysis, parting line and feed point determination, and finally feedback to The customer finalizes the draft. Only after the customer is satisfied can the drawing of the parts for manufacturing be determined, and then the processing flow can be prepared. The processing flow is shown in Figure 2-1-1-1. It can be seen from Figure 2-1-1-1 that using the traditional mold manufacturing process to process a qualified mold requires more manpower and material resources, and the production cycle is longer.

The process of using 3D printing technology to directly manufacture molds is shown in Figure 2-1-1-2 (take the SLM process as an example), which can be divided into three stages: pre-molding preparation, SLM molding and post-molding processing. Pre-molding preparations include 3D modeling of the mold model, STL format conversion, adding support structures, determining process parameters, and performing layered slicing. Data processing: The SLM molding stage is automated processing with less manual intervention and only needs to work on the SLM equipment The condition is monitored to ensure the normal operation of the equipment: post-forming treatment includes picking up parts, cleaning powder, sandblasting, surface grinding, polishing and other processing. The following specifically describes the process of using the SLM process to manufacture molds.