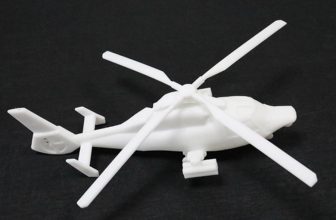

British Airways (British Airways) announced that based on the current application maturity, it has predicted the top ten applications of 3D printing technology to manufacture aircraft cabin parts in the aviation 3D printing field in the future. details as follows:

- Cutlery

- Auxiliary supplies such as toothbrush or comb

- Tray table

- Aircraft windows

- In-flight entertainment screen

- Seat

- Luggage

- Circuit boards for electrical parts

- Flight deck switch

- Aircraft skeleton

Considering the possibility of placing 3D printers on airports or even airplanes in the future, British Airways has compiled a list of ten applications that are expected to benefit from the technology in the future. Some of the predictions in this list cover current emerging applications, including 3D printed multimedia seats with surround sound effects, while convenience kit products such as toothbrushes and combs rank second, and 3D printed tableware tops the list.

The aerospace industry is a leading industry using 3D printing technology. However, as an airline operator rather than a commercial aircraft manufacturer, British Airways has a broader field of vision. The company pointed out: “3D printing is an important step towards a sustainable future for the aviation industry. The parts produced by 3D printers are both strong and durable, while reducing weight by 55%. During the life of the aircraft, every Reducing one kilogram of weight can save up to 25 tons of carbon dioxide emissions.”

British Airways’ focus on 3D printing is to follow the “BA2119 Future Aircraft Plan”. To celebrate the centenary of British Airways as the British flagship airline, the “Future Aircraft Project” aims to explore new concepts and reshape the customer experience for the future.

Through data reports collected from 13,000 consumers, leading industry experts and futurists, British Airways cooperated with the data research agency Foresight Factory to make some reliable predictions for future air travel. One possibility is that within the next ten years, biological scanners that collect passengers’ physiological and nutritional needs can give food and beverage recommendations to meet personal needs, and meet these needs through 3D printing on airplanes. A further step may be 3D printing emergency medicines to prepare for emergency needs at high altitudes.

British Airways has set the goal of achieving zero carbon emissions from flights by 2050. This field is still the real prospect of 3D printing applications, especially considering that the flights operated by British Airways have begun to use some 3D printed parts. The fleet currently consists of more than 280 aircraft provided by Boeing and Airbus. The two companies have taken key steps to integrate 3D printing technology with MRO and new part design methods.