FDM is a little difficult to print hollow models, and it is easy to damage the models, while light-curing 3D printing hollow models is easier, and it is often necessary to hollow out some models to turn them into hollow models for printing.

The advantage of hollowing out is

①Reduce the consumption of consumables;

②After hollowing out, the cross section is changed from a large area to an outer ring, which avoids the situation of detaching from the platform and unraveling of the model during large-area printing. Of course, this will also increase the difficulty of cleaning. If the inside of the model is not cleaned, it will easily cause the model to crack after a long period of time.

Basically all light-curing slicing software supports the hollowing function, but the hollowing algorithm of different software may be different, and the inner shape of the hollowing is different. we are generally hollowed out with magics, and the inner surface is more simplified and smooth after the magics are hollowed out. A more concise inner surface means fewer triangles, faster slicing process, and reduced computer operating pressure, which is very useful for slicing a large number of intermediate models. At the same time, because there are fewer complex inner surfaces, the difficulty of internal cleaning is alleviated.

The hollowing function of Magics will be briefly introduced from top to bottom:

The wall thickness will not go into details. The smaller the detail size, the finer the inner surface, the more it fits the undulations of the outer surface. Generally, we will simplify the inner surface a bit like the wall thickness.

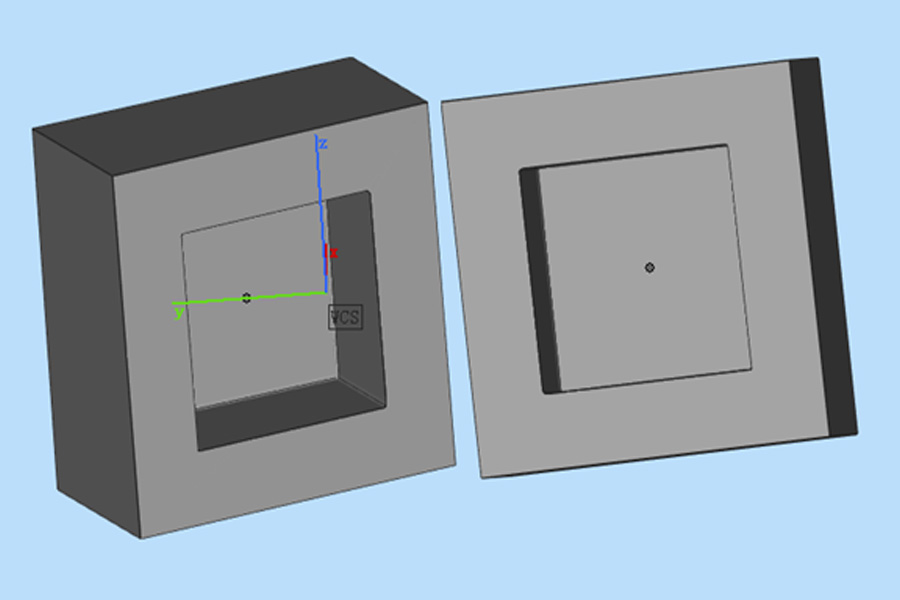

“Inward” naturally means hollowing out the inside of the model, and “outward” means putting a shell on the outside of the model, which is used to make molds and so on.

Through advanced settings, we design large tolerances, large angles, and get a very simplified inner surface.

The smooth core, increasing the percentage, will increase the complexity of the inner surface.

In addition, for some larger models, we may need a lattice structure. For how to make a lattice structure, we have introduced it in the past, and you can go to understand.

After hollowing out, it is naturally necessary to punch holes, otherwise the resin inside cannot flow out. When punching holes, you need to pay attention to 2 points:

①The diameter of the discharge hole, because the liquid has tension, the hole position that is too small is easy to be blocked due to tension and cannot be discharged. The thicker the wall, the higher the possibility of blockage, because the surface area of the liquid contacting the model is increased. In order to drain the liquid smoothly, a hole with a diameter of at least 2 mm is required.

②The pressure of the cavity is poor. I believe everyone knows that the leather squeegee used in the toilet can be difficult to pull off when it is buckled on a flat surface. This is caused by the difference in air pressure.

Similarly, after a part of the hollow model is printed, a structure similar to that of a skin will appear, which will greatly increase the bonding strength of the model on the platform, causing the model to fall off or cracks and splits in the Z-axis direction. At the same time, this will also cause some resin to flow out when the model is demolded. In order to avoid this situation, we not only need to punch holes at the bottom of the model when printing, but also need to punch holes at the top to ensure that the internal and external pressures are consistent.