Tungsten materials are the general term for a class of products that use metal tungsten as the main raw material, such as tungsten rods, tungsten wires, tungsten plates, tungsten bars, etc. Because of their good thermodynamic properties, they are widely used in chemical, military, national defense, medical, and nuclear power And other fields.

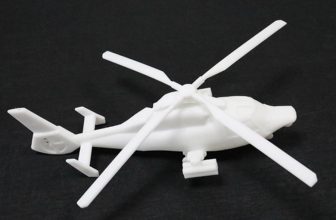

However, the high melting point and high hardness of tungsten make it very difficult to process, which in turn leads to low product quality and limited application areas. However, since the emergence of laser powder bed fusion technology in 3D printing, tungsten parts have ushered in new application opportunities.

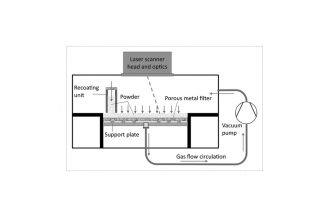

Laser powder bed fusion technology is an additive manufacturing technology used to manufacture metal parts. Lasers are mainly used to melt materials in the printing process. The density of tungsten parts manufactured using this method is relatively high, but heat treatment may still be required after printing. The purpose of heat treatment is to improve the hardness, strength, wear resistance and corrosion resistance of the product.

The use of 3D printed tungsten rods has low thermal expansion coefficient, high elastic modulus, strong resistance to electrical resistance and good thermal conductivity, so it can be used to make support lines, lead-in lines, printer needles, high-speed tools, and automobiles. Automatic products, sputtering targets, various electrodes and quartz furnaces.

Except for a small amount of tungsten filaments used as heating materials for high-temperature furnaces, heaters for electron tubes, and reinforcing ribs for composite materials, most of them are used to make filaments for various incandescent lamps and tungsten halogen lamps and electrodes for gas discharge lamps. Tungsten steel is gray or silver-white, with high melting point, high hardness, high density, good chemical stability, and strong ability to absorb radiation, making it an anti-radiation material, heat shield and other high-temperature or anti-radiation products Raw materials are preferred. In addition to being an ingredient in the manufacture of crankshafts and cylinders of automobiles, tungsten bars are also widely used in the manufacture of guns, artillery, rockets, satellites, airplanes, and ships.