Liangxu Vehicle Parts Co., Ltd. is a company specializing in the production of various exhaust pipes, intercooler inlet and outlet pipes, radiator outlet pipes, mudguard brackets, clamps and other auto parts. It is the main pipe product of China National Heavy Duty Truck Group. supplier.

Affected by the new standards, Liang Xu has been in contact with some new product development projects since the first half of 2007, and new product forms have brought new challenges. All kinds of pipe fittings and bracket products are Liangxu’s main products. Generally, Liangxu uses a portable three-coordinate for pipe fittings to complete the measurement work. After introducing new product development projects, they encountered new challenges in the measurement of bent pipes and some sheet metal parts.

For example, in the measurement of bent pipes, the usual method is to use the measuring arm to take three sets of points to locate a round surface. However, when the end surface is short to a certain extent, the data obtained by dotting will be misaligned with the actual data, resulting in measurement Is not accurate. Another example is the measurement of the fender bracket, which not only involves the hole position, but also involves the measurement of key information such as the shape of the elbow, the direction of the pipeline, and the size of the punching groove. The simple point-to-point measurement is when faced with this type of complex bracket. It fails.

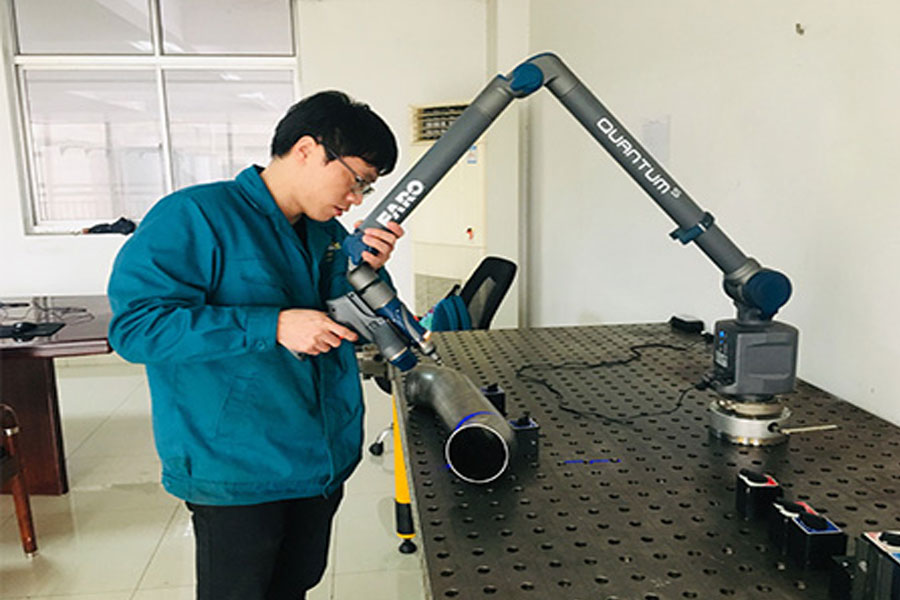

Introduce the 3D scanning arm

This kind of new products use the previous point-to-point measurement to have no way to carry out quality inspection, and can only use the scanning function.

The measuring arm has very high measurement accuracy. With the laser scanning head, it can perform point-to-point contact measurement and non-contact scanning measurement. The two operation modes do not need to disassemble any parts and can achieve seamless switching. The laser scanning head adopts blue scanning technology. Compared with the red laser, the blue laser has a shorter wavelength and is more capable of finding small details of the object. It can provide better scanning results with higher resolution. Since the actual scanning points per line can reach 2,000, the laser scanning head can capture the detailed features of complex parts. What’s more commendable is that even for parts with black surfaces and reflective surfaces, the laser scanning head can easily obtain accurate and complete point cloud data.

Now, Liangxu’s technical team can use the 3D scanning arm to scan the elbow and the fender bracket, and then compare with the digital model to get a color graphic quality report, whether the pipe is qualified, and which part is out of the tolerance range at a glance. Very convenient. From this, Liangxu’s technicians can confidently judge what to do next.

In Liangxu, the development of new products involves customizing molds according to customers’ design drawings, first production, first inspection, and customization of fixture inspection tools. Whether it is mold verification, first article inspection or customer loading verification, they are inseparable Open the scanning arm to provide accurate measurement guarantee.

The size of various pipe fittings ranges from 30 to 40 cm to 2 meters, and the measurement accuracy is required to be ±0.1mm. The scanning arm can fully meet Liangxu’s daily production needs in terms of measurement range and measurement accuracy.