Researchers at HRL Laboratories, a research center owned by General Motors and Boeing, have developed a new method of 3D printing parts using fracture-resistant ceramic matrix composites (CMC). The HRL team developed a new type of siloxane-based ceramic resin, reinforced it with inert particles, and then converted it into silicon oxycarbide (SiOC) using an extreme heating process called pyrolysis. The resulting glass-like material has enhanced durability, and according to the research team, it can be used in new energy sensitive fields such as propulsion, energy production and chemical processing.

“The challenge we solved in this project was to integrate the toughening solution with our 3D printing process.” said Mark O’Masta, the lead researcher of the HRL project. “We can now add these reinforcement materials in large quantities to significantly enhance The toughness of 3D printed ceramic parts. We basically make brittle single-molecule materials into durable composite materials. As an added benefit, adding steel bars can alleviate certain processing constraints.”

Expanding the application of 3D printing ceramics

Ceramic components usually have excellent corrosion and wear resistance, and their unique properties make them have potential applications in high-temperature areas, but it turns out that molding them is problematic. The use of fragile ceramics to manufacture complex parts with narrow geometries can also create pressure on internal cracks and voids, which can sometimes lead to catastrophic failures. O’Masta explained: “All ceramic parts, whether traditionally processed or 3D printed, have tiny defects, such as tiny voids created during processing, handling, and repair. The problem is that when stress is applied to the area At times, the defect can become an uncontrolled crack, leading to catastrophic damage to the entire part.”

Ceramic 3D printing technology may still be in its infancy, but in order to solve this problem, commonly used technologies have begun to appear. Attempts have been made to mix direct ink writing (DIW) and fused deposition modeling (FDM) methods, but more commonly, photopolymerization (SLA) is used to cure the raw material injected into the polymer.

In each existing process, the printed “green body” undergoes a two-step heat treatment to remove polymer (degreasing) before sintering the ceramic particles. Now, recent research has produced an alternative method that involves replacing 3D printing with a siloxane-based resin and then converting it to SiOC by pyrolysis. This emerging ceramic manufacturing technology eliminates lengthy debinding and sintering steps, and may make it a faster alternative to traditional ceramic printing processes. In order for this new temperature-based method to work effectively, a ceramic material needs to be developed to address the material’s low inherent toughness and prevent poor particle fusion.

HRL Labs’ novel 3D printing ceramic method

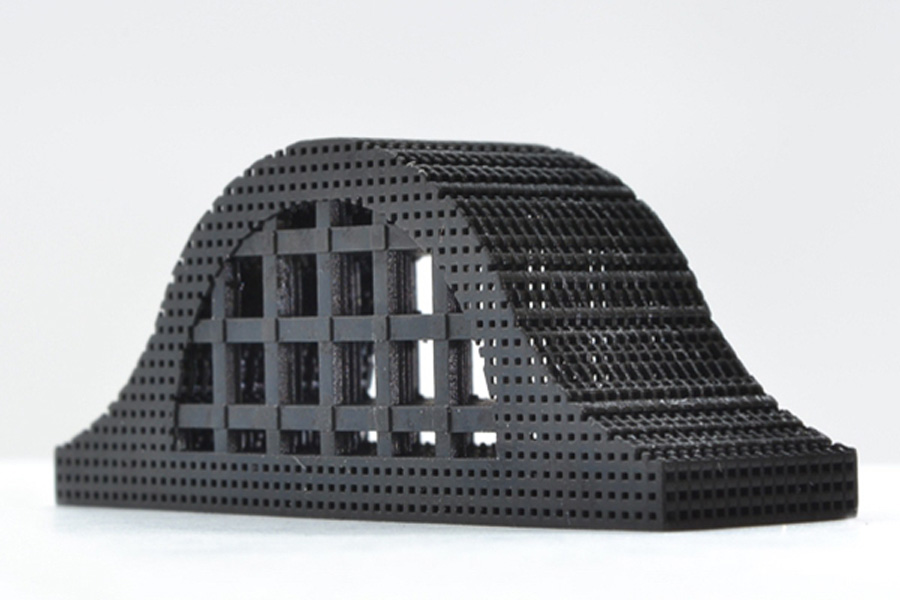

In order to solve the inherent fragility of ceramics, the HRL team developed a novel process that required the development of ceramic fiber reinforced CMC. The researchers formulated their new resin using a mixture of a photoinitiator and silicon oxycarbide (SiOC) material, which contains dispersed inert ceramic particles.

Using the Prodways ProMaker L5000 industrial printer, the researchers subsequently manufactured a series of samples of 1.25(t)×2.5(h)×15(l)mm3 in order to evaluate and optimize its formulation. After a series of characterization tests, the team found a high level of particle dispersion, but it also exhibited strange behavior in enhancing the tensile strength of the component. It turns out that thicker samples are more likely to crack than thinner ones. Through this discovery, the HRL team determined the “sweet spot” of the level of enhancement that can be achieved. Adding too many reinforcing elements will exceed its “stacking limit” and weaken the part, while insufficient addition may make the ceramic easy to crack.

Having been working on this technology since 2016, the research team believes that they may eventually produce a well-dispersed reinforced ceramic with reduced shrinkage after heating. Products printed with reinforced materials have three times the wall thickness and toughness above 3 MPa, which led the HRL team to conclude that new, more complex ceramic parts can now be used. Ekaterina “Katya” Stoneevitch, co-author of the HRL study, concluded: “Through detailed research and careful inspection of defects using optical and electron microscopes, we were able to determine the appropriate processing conditions. With this information, we found that we can print more than before. Thick parts.”

Ceramic innovation in 3D printing

Although ceramic additive manufacturing is still fully optimized for high-stress end-uses, many companies have already commercialized the technology. Scientists at the Fraunhofer Institute for Ceramic Technology and Systems (IKTS) have developed a multi-material jet (MMJ) system that can produce reinforced ceramic parts. The new machine combines materials such as metals and ceramics to take advantage of their comprehensive performance.

The Dutch-based 3D printer manufacturer Admatec has launched a new modular DLP 3D printer that is also compatible with ceramics: Admaflex300. The system is designed to meet the needs of the investment casting industry for the production of large alumina parts and silica. Core or shell.

Elsewhere, material jetting specialist XJet collaborated with Straumann to improve the capabilities of its ceramic 3D printing technology in the dental field. By adopting XJet’s additive manufacturing system, Straumann is able to design and manufacture dental parts with complex geometries using normally fragile materials.