In industrial machinery products, many composite structural components will withstand very high working loads, which will cause material damage and lead to a decrease in mechanical performance. Continuous monitoring of the integrity status of components and the evolution of internal damage is essential to improve operational reliability and the life of composite structures.

In recent years, sensing solutions for self-induction have been developed, mainly based on the use of optical fibers. However, in view of the complexity of implementation and the limited reliability of the methods used, there is no effective method for damage monitoring of composite components. In addition, due to technical and cost reasons, it is impossible to build a particularly dense optical fiber network, so it is difficult to detect damages or damages that exist in fiber-poor areas on a microscopic level.

The production of traditional self-induction composite parts is usually a complex multi-step process, requiring specialized equipment to integrate continuous fibers. The goal of Brightlands Materials Center, a research institute in the Netherlands, is to use additive manufacturing-3D printing to produce self-inductive components with carbon fiber composite materials, and to use the advantages of the two technologies to obtain more effective results.

Next-generation smart materials

Self-induction is the ability of a material to act as a sensor and collect information about its own condition. Polymer matrix composites with infused continuous carbon fibers have been used as self-sensors to measure changes in fiber resistance. Self-inductive materials with sufficient fibers have application potential to monitor the structural health of large parts in aerospace and other machinery or bridges.

However, the production of traditional self-induction composite parts is usually a complex multi-step process that requires specialized equipment to integrate continuous fibers. The Brightlands research team used continuous carbon fiber 3D printing technology to achieve a breakthrough.

The team pointed out that 3D printing technology can accurately position carbon fibers in composite parts, so that the placement and direction of the fibers extend along the key areas where they are needed, and the fibers can also be grouped in batches. The advantage of this approach is that it provides more sensitive monitoring when needed. The design freedom brought by 3D printing technology for material positioning makes these possible.

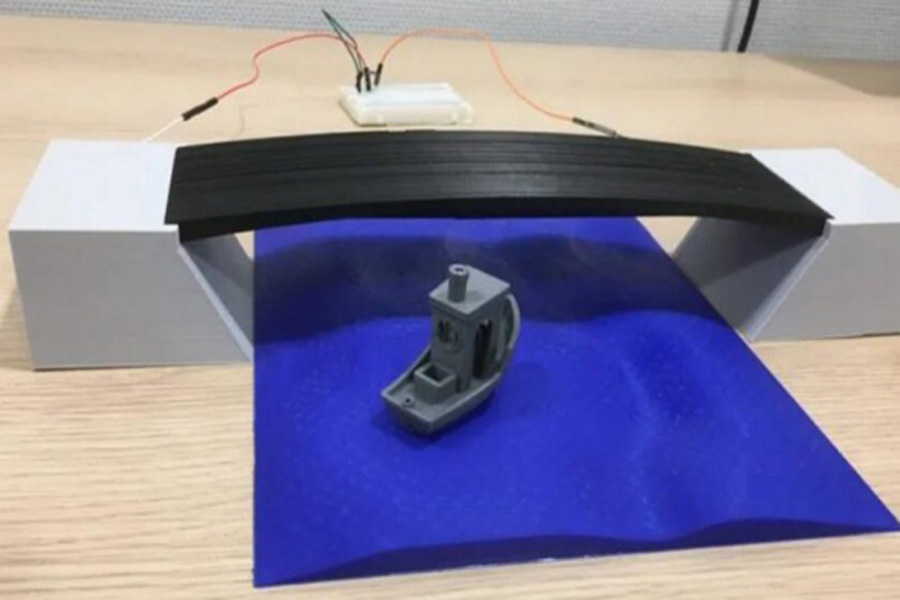

Brightlands researchers conducted an experiment to verify the 3D printed sensor fibers by monitoring the deformation of the pedestrian bridge model. The team used Anisoprint’s carbon fiber composite 3D printer to create the curved beam of the bridge model, and the printing material was carbon fiber thermoplastic composite. The 3D printing equipment extrudes the material and periodically inserts it along the build direction, thereby generating anisotropy. When energized, several optical fibers extend out of the bridge, and their resistance is measured under varying loads.

The results show that there is a clear correlation between the load applied on the bridge and the electrical resistance of the continuous fiber, and the electrical resistance increases with the increase of the force. The results initially verified the potential of 3D printed continuous carbon fiber composites in the application of self-inducing parts. 3D printed self-inducing parts can provide useful data about which parts of the component bear the maximum load or the force range that the component needs to bear. The research team hopes to extend this technology and these data to areas such as prosthesis manufacturing. Engineers can use these data to design prostheses to more effectively distribute stress or build bridging structures to support larger loads.

The coupling between the electrical and mechanical responses of materials is a phenomenon called piezoresistance. This coupling phenomenon can be used to develop strain-sensitive’smart’ materials that can monitor their own strain and internal damage status. One way to achieve this goal in polymer composites is by incorporating conductive carbon nanostructures into non-conductive polymers. When containing enough carbon nanostructures, the polymer composite becomes conductive-a phenomenon called electroosmotic flow. During percolation, changes in strain, humidity, temperature, and other external excitations lead to changes in the electrical conductivity of nanocomposites, and their correlation can be used to develop self-inducing smart materials. [2]

Current applications of these materials are expected to provide next-generation smart materials for the automotive, aerospace, transportation and energy industries. On the other hand, the applications of carbon-filled elastomer materials are more focused on human motion sensors, soft skins, smart wearable sensors and robotics. [2]

Regarding the application of carbon fiber composite materials to make smart parts, according to the market observation of 3D Science Valley, Arris Composites, which provides continuous carbon fiber 3D printing technology, includes this segment in its developed market applications. Arris Composites’ technology has been applied in multiple markets, using revolutionary continuous carbon fiber reinforcement to make products lighter, stronger, and smarter. At present, consumer electronics products are Arris Composites’ fastest-growing market, and its next-generation consumer electronics devices are designed to be lighter, smaller, and smarter. 3D printing technology makes the product update cycle short and the pace of innovation is fast, and portable electronic devices are likely to be the first manufactured products that Arris provides to the public.

In addition, it is worth mentioning that the continuous carbon fiber composite 3D printing technology involved in the Brightlands research has matured day by day, and the application target is not the manufacture of prototypes, but mass production. Arris Composites aims to achieve the next generation of mass market continuous fiber composite materials 3D printing production-level applications. Arris Composites realizes the mass production of high-strength and lightweight composite parts through its proprietary Additive Molding™ manufacturing technology. Through this new process, high-grade carbon fiber materials can be produced at the same speed as plastic molded products.

Will the increasingly mature 3D printing technology of carbon fiber composite materials inject new vitality into the manufacturing of next-generation smart materials or smart parts?