Although 3D printed cars have developed significantly, it may take some time to enter the mass production era. Most 3D printed car projects are either prototype cars or 3D printed car parts. And despite considerable progress in optimization, design and sustainable development, 3D printing technology still cannot print the entire car. Under this circumstance, some people think that 3D printing is just a gimmick, and it has little significance in the entire production system of the automobile industry. Is this really the case?

In fact, this question already has a clear answer in major auto factories. Although 3D printing hasn’t been able to produce core parts similar to the three major auto parts in batches with low cost and high efficiency. However, in other aspects, 3D printing can indeed play a good substitute role, and it is the icing on the cake in the production chain of the whole vehicle.

3D printing is mainly concentrated in the auto parts market

Lightweight body parts is an important factor for Japanese cars to reduce weight without reducing their strength. Some friends think that Japanese cars are light and not crashworthy. However, the recent crash test results of the China Insurance Research Institute also confirmed that Japanese cars with a “lighter” body are safer. The safety strength of the body structure is not directly related to its own weight. For example, aluminum alloy and steel plate materials commonly used in automobiles, although aluminum alloy is lighter, its strength is much higher than that of steel plates, and it is also more resistant to crashes.

In terms of car body manufacturing, Japanese companies have added 3D printing to their production lines as an ace weapon. At the beginning of this year, Honda’s R&D department cooperated with software company Autodesk. The two parties designed a crankshaft component and used 3D printing technology to manufacture samples, thereby reducing the weight of the vehicle and improving the fuel economy of the engine. Because of the particularity of the material and manufacturing process of the crankshaft components, the overall structure of the crankshaft has not changed much since the birth of the engine. Nowadays, with the application of 3D printing technology, Honda’s design plan will achieve the goal of reducing weight by 30% compared with the aforementioned products, which can be said to be a new breakthrough.

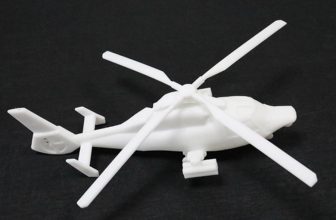

In addition, Honda has been committed to using 3D printing technology and intelligent design solutions to optimize the design of auto parts. So far, Honda has upgraded many types of auto parts such as seat belt brackets, engine control units, and frames, and has also used 3D technology to reduce the weight of body parts. Speaking of lightweight, 3D printing can print a variety of materials with different mechanical properties at one time. This feature is used by many manufacturers in the product design and R&D evaluation of automotive interior parts. Parts composed of various materials and processes, such as steering wheels, dashboards, air-conditioning exhaust fans, and automobile joysticks, can all be prototyped with the help of 3D printing technology and equipment.

For example, in 2017, Mercedes-Benz took an important step in the transformation of the manufacturing industry: the use of 3D printing technology to produce metal parts, including the use of cast aluminum alloy 3D printing Mercedes-Benz truck thermostat. Not only that, Mercedes-Benz stated that this link has passed all strict quality tests. And Porsche is using 3D printing technology to print a new form of full bucket seat this year. The seat uses new materials and uses 3D printing technology to build a unique structure. The new seat is not only more ergonomic, but also lighter in weight. And better ride comfort. According to Michael Steiner, a member of the Porsche R&D Executive Committee, with the introduction of a new 3D printed full-bucket seat, Porsche can once again provide mass-produced car customers with the opportunity to experience motorsport.

Porsche can provide customers with customized services. Customers can choose from three hardness levels: soft, medium and hard. Porsche plans to produce a limited number of 40 3D printed custom seats in 2020 for use in Porsche 911 and 718 series models, with six-point seat belts used on the track. After receiving feedback from these customers, Porsche will launch it in a customized service in mid-2021.

Integrating 3D printing technology into the car manufacturing process, Mercedes-Benz and Honda are just the tip of the iceberg. BMW, Volkswagen, Ford, Honda and other car companies are exploring the more possibilities that 3D printing brings to car manufacturing in their respective design centers. Compared with the traditional car manufacturing process, 3D printing technology can save more for car companies. It shortens the time from R&D to market, but the current 3D printing technology can only be applied to the production of auto parts. Don’t underestimate these auto parts. 3D printers can work 24 hours a day, and can perform reverse production through the received data, which can make the entire car manufacturing process more flexible and changeable, and can make the car manufacturing industry more flexible. Efficient.

3D printing changes the “rules of the game” in the electric vehicle industry

Especially for the electric vehicle industry, 3D printing lightweight parts will “change the rules of the game.” At present, in the promotion of electric vehicles, consumers’ concerns about limited cruising range are a major obstacle, and lighter vehicles can not only improve fuel economy, but also extend vehicle cruising range.

Take Tesla as an example. As an absolute leader in the electric vehicle market, Tesla seems to use a multi-axis polymer DED process to deposit materials on the 3D surface of injection molded parts to regenerate the desired shape. In metal cladding, similar methods of repairing parts are common to some extent, but they have not been seen in the production of polymer parts. Stratasys and Siemens (as well as Boeing and Ford) have been working on this 3D printing hardware, mainly for depositing composite materials.

On this basis, Tesla Motors hopes to use 3D printing technology more widely to improve production efficiency. A few days ago, Tesla released the latest recruitment notice, recruiting additive manufacturing technicians for the Nevada super factory in the United States. It mentioned the rapid development of additive manufacturing business. It can be seen that Tesla is optimistic about the potential of 3D printing technology. More applications may be invested.

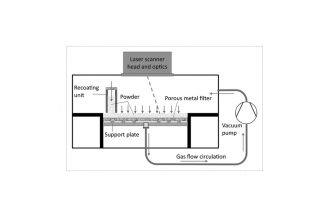

Tesla’s official recruitment notice read: “Tesla is looking for a successful person with the skills required to operate SLA/SLS/FDM 3D printing equipment to further expand the fast-growing additive manufacturing business.” Tesla also listed the main responsibilities and qualification skills in the recruitment notice, including the ability to build different system functions and to guide all work related to machine maintenance. At the same time, it has 3D printing work experience and loves rapid prototyping and 3D printing industry. In terms of professional skills, Tesla requires familiarity with CATIA, SolidWorks, Pro E, Rhino or other CAD drawing software, and has more than 2 years of relevant education or technical certificates.

Perhaps one day we will see more and more examples of the application of 3D printing technology in Tesla’s models, and eventually we will use 3D printing technology to manufacture complete vehicles. However, there is already a company that is infinitely close to fulfilling Tesla’s “ultimate dream”.

This company is XEV. XEV comes from Europe and is headquartered in Turin, Italy. The team consists of well-known car companies such as BMW and Volkswagen. XEV pioneered the application of 3D printing technology to automotive R&D and production to achieve the goal of reducing vehicle manufacturing costs and meeting highly customized needs.

The core of XEV’s innovative automobile factory is the intelligent additive production solution. Through the cooperation of multiple automobile-grade intelligent 3D printers, it can achieve an environmentally friendly, efficient and low-cost automobile 3D printing production line. The XEV innovative car factory can reduce costs and new car development time by up to 90% compared to traditional car production lines. In addition, in terms of safety, 3D printing technology can start from the internal structure of the parts, thereby improving the strength of the parts. Compared with the parts produced by traditional processes, the strength is higher and the safety is better.

In March 2019, XEV signed the world’s first automotive-grade additive vehicle production contract with JMC in Jeju, South Korea. This smart production solution includes 50 3D printers and 4 post-processing stations, with a total price of more than 3 million euros. . At the same time, XEV also has in-depth cooperation with well-known car companies such as BMW and Volkswagen to provide them with world-leading intelligent production solutions.

The 3D printed car YOYO is the latest product of XEV. Although it is only the first batch of prototype cars, YOYO has obtained multiple certifications. After PT0, YOYO will also go through PT1, PT2, SOP and other production line verification processes to verify the accuracy of the mold, the rationality of the production process, and the final certification of the final assembly line station beat, vehicle assembly and test. After passing the E-Mark certification (EU certification), it can be sold in the European market.

As the world’s first mass-produced 3D printed new energy vehicle, YOYO is small but the space is not small. The interior has been thoroughly tested for ergonomics, and everyone can find their most comfortable sitting posture. In addition to zero emissions, pure electric will release a lot of space, and with the borderless door design and panoramic sunroof, it will bring an unparalleled transparent experience. The biggest feature of YOYO is safety. In terms of safety, 3D printing technology has unique advantages: for example, the internal structure of the parts is easier to control, and the strength of the parts can be improved, which will also improve the safety and reliability of the entire vehicle.

It is reported that the first batch of YOYO new energy vehicles will be delivered at the end of December this year, and more than 34,000 YOYO new energy vehicles have been booked in Europe. XEV will be China’s largest new energy vehicle export company and will also expand the domestic market in the next few years. I don’t know if a 3D printed car weighs 550 kg, will you buy it?

Car evaluation

Using 3D printing technology can better meet the needs of car companies. In the highly competitive automobile manufacturing industry, more and more manufacturers have adopted 3D printing technology for low-cost testing products and manufacturing customized accessories before mass production. Although the mainstream 3D printing technology at this stage only stays in the sample production stage, it has not yet entered the mass production link. But just in the sample trial production stage, it has already saved a lot of cost and time for the enterprise. I believe that in the future, 3D printing is bound to bring major breakthroughs to the car industry, and mass-produced 3D printed new energy vehicles like YOYO will increasingly appear in the car purchase list.