ETHEC City is a student project in Switzerland that aims to fundamentally change the way of travel tomorrow through today’s technology. In response to the challenges of climate change and sustainability, the team has developed an ingenious two-wheel drive electric motorcycle that can save energy and increase cruising range.

Tobias Oesch studied mechanical engineering at ETH Zurich and is the technical leader of the ETHEC city project. In a team of 9 other ETH students, he accepted the challenge and developed a prototype of an electric motorcycle in just one year-from concept to construction, installation and testing.

Tobias is committed to solving one of the main problems in today’s automotive industry: sustainability. He said: “If we want to solve the problem of climate change, we must make major improvements to our urban and suburban traffic.” Motorcycles are more efficient than ordinary cars, but we can hardly see all-electric motorcycles on the streets – we must Change. “

In ordinary motorcycles, about 80% of the energy is lost especially on the front wheels, which leads to a significant reduction in the mileage of electric vehicles. The team’s approach to this problem is very clever: “We decided to also integrate an electric motor in the front wheel so that we can use it as a generator to retune the entire movement energy back into the system,” Tobias explained. By restoring the braking force with a two-wheel hub motor, a longer distance can be reached with a smaller battery, thereby greatly improving the efficiency of the motorcycle. For students, the project is part of a broader prospect: “ETHEC cities are mainly research prototypes for us to study this recycling method and therefore improve the electric vehicle industry in the future.”

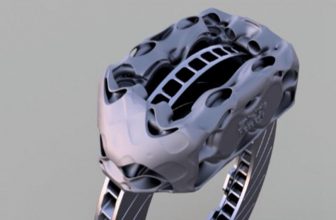

Due to the small budget and the tight time frame to build motorcycles, traditional manufacturing methods soon became unsuitable for fleets. As Tobias said: “Because it is a prototype, we usually only need one artifact instead of a thousand. In this case, the ideal is to add technology.” The team decided to use Stereo Lithography (SLA), Selective Laser Sintering (SLS) and Selective Laser Melting (SLM) to 3D print several design components of the casing, as well as structural components, such as the installation of spikes. Tobias emphasized the degree of freedom students gain by implementing these technologies: “Using 3D printing, you can build more complex structures, which allows you to combine multiple functions into one part.” Fewer parts means lower Cost, and more importantly, lighter weight-this is a key advantage,

Laser sintering as power

When constructed as end-use parts, the demands placed on 3D printed objects are high: in addition to being lightweight, they must also be strong and durable-the material properties are very suitable for selective laser sintering. When students started looking for partners, the Swiss-based SLS printer manufacturer Sintratec decided to sponsor multiple components to support the project. Subsequently, laser sintering of parts such as the display housing or fuel filler cap was performed on the Sintratec S2 system. Use Sintratec PA12 nylon powder-convincing. Tobias pointed out: “The quality of Sintratec products is very accurate, and the surface quality is very good.” «Especially display cabinets must be durable enough to withstand wind and rain, strong enough to withstand mechanical shocks, and strong enough to be used without deformation . “For ETH students, SLS components meet these requirements.

Bright prospects for electric mobility

After painting, the team assembled the Sintratec parts and is now close to completing its prototype. Tobias said: “We are very happy to cooperate with a company in Switzerland because we have very close ties and no delivery delays.” What is his comment on SLS technology? «For our application, SLS is the best manufacturing solution. However, when it comes to larger series, it can become very expensive, and I think there is still a long way to go in terms of mass production. »Using a system like Sintratec S2-suitable for small and medium-sized series-the industry’s potential is obvious. Tobias concluded: «I think SLS technology undoubtedly has a place in the automotive field. It will play an important role in future prototype development and vehicle development! »The future of travel is expected to be shaped by projects such as ETHEC city.

“SLS technology undoubtedly has a place in the automotive field, especially in the development of prototypes and vehicles for the future.”-Tobias Oesch Technical Director ETHEC Urban Mechanical Engineering student ETH Zurich Federal Institute of Technology