For those who follow various projects aimed at additive manufacturing on the moon or Mars in the distance, they may not have thought: what about oxygen? How will astronauts breathe when constructing future space habitats?

In order to solve the problem of regular oxygen supply on the moon, the European Space Agency (ESA) is exploring the possibility of an oxygen plant that may rely on existing technology on Earth. Oxygen is a by-product of the metal refining process and is used to make 3D printed metal powders. Although oxygen has not been used on our planet before, the company realizes that oxygen can provide far-reaching uses for space.

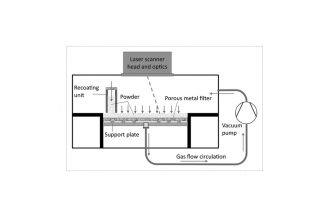

Lunar dust or heavy lunar rocks are tiny layers of rock covering the moon, no different from minerals on the earth. It is composed of 45% oxygen combined with metals such as iron and titanium. The process of extracting oxygen is called molten salt electrolysis. Before applying the electric current, the minerals were placed in the molten calcium chloride salt heated to 950°C in a dedicated room. Oxygen is attracted to the anode, leaving metal powder. “A few years ago, we realized that seemingly unimportant by-products from the terrestrial mineral extraction process may have far-reaching applications in space exploration,” said Ian Mellor, managing director of Metalysis. “We hope to continue to explore with ESA and our industrial partners how to make our earth technology available in space.”

When ESA established a prototype oxygen plant in the Materials and Electrical Components Laboratory of the European Space Research and Technology Center (ESTEC) in Noordwijk, the Netherlands, in January 2020, it proved that the process can be applied to rearrangement stones. . Beth Lomax of the University of Glasgow said: “In Metalysis, the oxygen produced by the process is a harmful by-product, but is released in the form of carbon dioxide and carbon monoxide, which means that the reactor design itself cannot withstand oxygen. Therefore, we have to The ESTEC version was redesigned to be able to measure oxygen. The laboratory team was very helpful in installation and safe operation.”

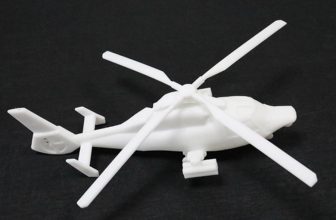

As the project continues, the team is exploring the possibility of collecting and storing oxygen, as well as the possibility of 3D printing the metal produced during use. This includes answering questions such as whether these metals can be 3D printed directly or need improvement. The exact combination of metals in the go stone depends on where you get it on the moon. Advenit Makaya, ESA materials engineer in charge of the project, said: “This project will help us learn more about the Metalysis process, and may even become a stepping stone for the establishment of automatic pilot oxygen production equipment on the moon – plus the additional benefits of metal 3D printers. Can be used to make alloys for building materials.”

Oxygen will eventually be used to provide breathable air and rocket fuel, and these metals can be used for 3D printing on the moon, including for habitat construction. It will be possible to sustain life on the moon without the cost of sending materials from the earth.

Comments:

Obtaining oxygen from resources found on the moon is obviously very useful for future moon landers, whether it is breathing or producing rocket fuel locally. Now that we have the facility in operation, we can fine-tune it, for example, by lowering the operating temperature, and finally design a version of the system that can one day fly to the moon for operation. “

At the same time, decomposition is perfecting oxygen extraction technology to produce as much gas as possible to maximize its use in lunar applications. Modifications include changing the current and reagents to increase the amount of oxygen.

At the same time, they are trying to lower the temperature required for production temperature to reduce energy costs. The cabin will also be made smaller so that it can be sent to the moon more efficiently.

In addition, ESA and Metalysis launched a challenge to seek external engineers to develop an in-process monitoring system for tracking oxygen production. The overall goal of the project is to create a pilot plant that will be able to operate sustainably on the moon.