In a case study recently released by Moscow-based Thor3D, we saw how their Calibry 3D scanner has made a huge difference in the production of children’s foot orthoses in Germany. Phoenix GmbH & Co. is an engineering company specializing in the development of 3D printing technology products. Its mission is to improve the creation of orthotics in German clinics.

By using Calibry Nest software, Calibry 3D scanner, Geomagic Wrap software with algorithms created by Phoenix, and Tractus 3D printer, Phoenix was able to develop a new and repeatable solution. This new process can save doctors up to 40% of the production time. It is so simple that it can be used by orthopedic surgeons who have no previous experience with 3D tools. “Before Calibry, we had to use more expensive and less easy-to-use scanners to accomplish the same task. This is a limiting factor in B2B scanning applications because users are not scanning experts.” 3D scanning and additive manufacturing application engineer Emil Wörgötter Said.

More importantly, it provides a new level of comfort for children. Historically, the installation of prostheses or orthotics can be a long and painful process for anyone, especially children who need to grow. 3D printing has proven its performance in hand and arm prosthetics in countless instances, can help amputees, and also provides a better way to adapt children to orthopedics.

The latest case studies show some of the biggest advantages of 3D printing, as children can enjoy fully customized medical devices that can be resized in minutes instead of hours. They may eventually be able to walk more comfortably. In sharp contrast to the old-fashioned and inefficient methods of correction, the first is to measure and model the foot pads. Afterwards, use plaster to shape the orthosis-this is not only troublesome, but can be difficult when testing the patience of the child. Orthopedic specialists are required to perform this work, which may require very high maintenance; in fact, if one step goes wrong, the entire uncomfortable process may have to be repeated from the beginning. However, an affirmative form will eventually be created.

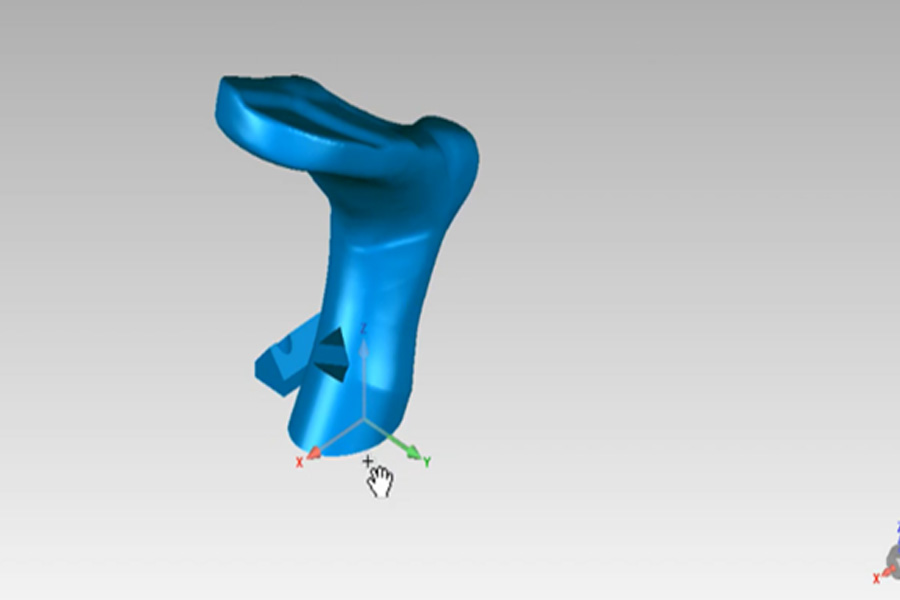

When using the Calibry 3D scanner to create the orthosis, the Phoenix team still needed the previously fitted orthosis

“Currently, in the production of orthotics, the traditional process of creating an initial positive form must be retained. Frontal scanning is different from foot scanning.” Phoenix points out in the case study. “The 3D scan has many anatomical details of the existing foot that needs to be treated, while the conformal shape simplifies the anatomically correct geometry. Currently, Phoenix is developing an algorithm that will also automatically create an initial positive form. Therefore, in the future The production of orthotics will become completely contactless.”

Vacuum thermoforming of new type orthosis shell

After measuring the feet and scanning the patient’s body shape, they were able to 3D print and then vacuum thermoform to create a new shell. Patients will not feel discomfort or wait for a long time, and since all data remains online, there is no need to store tables.

Comments: Orthotics are expected to continue to develop through 3D printing because they are a smaller product, easy to produce, and can now be manufactured faster and more economically through amazing customization.