“Life is like a box of chocolates. You never know what the next piece will taste like.”

The market for traditional toys is declining, and adult toys continue to grow. According to statistics from the China Toy Association, about 64% of adult consumers are interested in buying toys. It is estimated that the toy market for adults is worth about 50 billion yuan per year. In 2020, more than 18 million people will buy trendy toys. If traditional toys are aimed at children and adolescents, figure models based on film and television animation will occupy young people in the animation circle, and the blind box will further stimulate the mainstream circle.

Different from children’s toys, blind box toys are more personalized, unique, well-made, have decorative functions and collection value, and are similar to hand-made toys, with their story background or culture behind them. The expansion of the trendy play market reflects the unique consumer concepts and consumer psychology of the current young people. As the main consumer of the new generation, the post-90s and post-00s have stronger cultural self-confidence and higher quality of life requirements, pursue individuality, focus on happiness, like being different, and willing to pay for “good design” and “high quality.” These blind box games are not only for fun, but also a spiritual sustenance, an expression of self-personality.

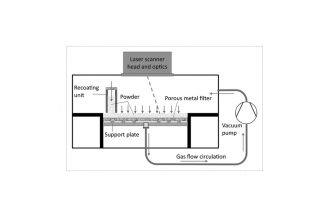

With the upgrading of the consumption structure and the changes in the attributes of the consumer groups, the mass production of traditional toys and the mode of winning by quantity have become obsolete, and mass-produced toy products have been unable to satisfy the pursuit of today’s young people. Facing the needs of the toy market for individualization, diversification, and rapid iteration, more free and customizable 3D printing will provide toy manufacturers with assistance in their transformation in response to market changes. The high degree of customization and the model of on-line products, rapid response to changes in production, and low-cost development have shaped the important competitive advantage of 3D printing in the toy industry.

For the development and production of blind box products, 3D printing technology is undoubtedly the best choice.

First of all, it is easier to customize:

Personalized customization is the biggest feature of 3D printing that distinguishes traditional iso-material manufacturing and subtractive manufacturing. It can produce multiple styles of products at one time to meet diversified, varied, and personalized needs. It is for manufacturers to try small batches in the early stage. Compared with open mold manufacturing, 3D printing can better control costs and make adjustments.

Specialized structure manufacturing ability is strong:

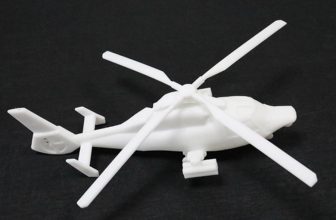

3D printing can achieve many complex structures, and even can create structural models that cannot be manufactured by traditional manufacturing. Print any curved surfaces and products with hollows and hollows. It is easier to make breakthroughs in the creative realization of blind box products. The advantages of personalized fashion play are huge.

Shorten the product development cycle:

3D printing can use three-dimensional data models for manufacturing. Only by modifying the model data, the corresponding changes can be directly produced. This can greatly shorten the product development cycle, help manufacturers cope with the rapidly changing tastes of consumers, and quickly seize a certain blind box. Separate the product market in the cultural field to enhance the competitiveness of enterprises.

New models will become possible:

The core of the blind box product lies in its exquisite design, and 3D printing technology is based on 3D data model manufacturing, which gives manufacturers another unique model: build consumer communities, obtain ideas from the community and implement them quickly, and can be explored by players To develop more diversified peripheral accessories products such as product clothing, decorations, scenes, etc., to greatly expand the width of the product, and this derivative is a product that players will love to vote by their feet! Manufacturers will be positioned as the downstream end of creative realization and commercialization, and each user is a potential member of the product chain, thus realizing truly highly personalized customization.

In Guangdong, the world’s largest toy manufacturing area, 3D printing is not unfamiliar to many toy manufacturers, and the rise of blind boxes and other trendy games will greatly change the product development and production models of manufacturers. 3D printing technology will Manufacturers’ competitiveness multipliers will also bring more high-quality products to consumers. It is foreseeable that the blind box will inevitably be inseparable from 3D printing in the future.