With the continuous development of society, materials with a single texture can no longer meet people’s requirements for various properties of materials.

Use substrates of different properties for compounding, and give full play to the complementary advantages. While not too much damage to other properties of polymer materials, some specific properties can be greatly improved, or some new uses can be given to further Broadening the application fields of polymer materials has gradually become an inevitable trend in the development of new materials. This article mainly introduces the characteristics of 3D printing nylon glass fiber.

Introduction To Glass Fiber

Glass Fiber is an inorganic non-metallic material with excellent performance, which mainly contains inorganic salts such as silica, alumina, magnesia, calcium oxide and sodium oxide. The diameter of its monofilament ranges from a few microns to tens of microns, which is about 1/20~1/5 of a human hair. In actual use, glass fibers often need to be bundled and used, and each fiber strand is composed of hundreds of fiber monofilaments. Glass fiber is widely used in various fields of the national economy as a reinforcing material, thermal insulation material and electrical insulation material in composite materials.

The basic characteristics of glass fiber mainly include

- ① High tensile strength and low elongation (generally less than 3%).

- ②The coefficient of elasticity is large. The rigidity is better.

- ③It is an inorganic fiber, which is not easy to burn and has good chemical resistance.

- ④Small water absorption, can transmit light.

- ⑤The heat resistance and dimensional stability are better.

- ⑥The price is cheap, and it can be melted into glass beads under high temperature.

Compared with organic fibers, glass fiber, especially glass wool, has the advantages of high temperature resistance, non-combustibility, corrosion resistance, electrical insulation, and good heat and sound insulation properties, but it is brittle and has poor wear resistance. Glass fiber has good applications in electrical insulation materials, industrial filter materials, anti-corrosion and moisture-proof, heat and sound insulation and shock absorption materials. Glass fiber can also be used as a reinforcing material, such as reinforced plastic or rubber reinforced plaster or cement.

Introduction To Nylon Glass Fiber

Nylon glass fiber is a kind of white powder. Compared with ordinary plastics, its tensile strength and bending strength have increased, the heat distortion temperature and the material’s modulus have increased, and the material’s thermal deformation and shrinkage rate have been reduced. The surface becomes rough and the impact strength is slightly reduced. Studies have shown that adding 30% of glass fiber to PA can significantly improve the mechanical properties, dimensional stability, heat resistance, and aging resistance of PA, and its fatigue strength is 2.5 times that of unreinforced. Nylon fiberglass materials are mainly used in the fields of automobiles, home appliances, and consumer electronics. The molding process of nylon glass fiber material is roughly the same as that of unreinforced nylon, but due to the increase in melt viscosity, the injection pressure and injection speed should be appropriately increased, and the barrel temperature should be increased by 10°C~40C. During processing, the glass fiber will be oriented along the direction of melt flow, thereby enhancing the mechanical properties and dimensional stability in the orientation direction.

The Properties Of Nylon Glass Fiber

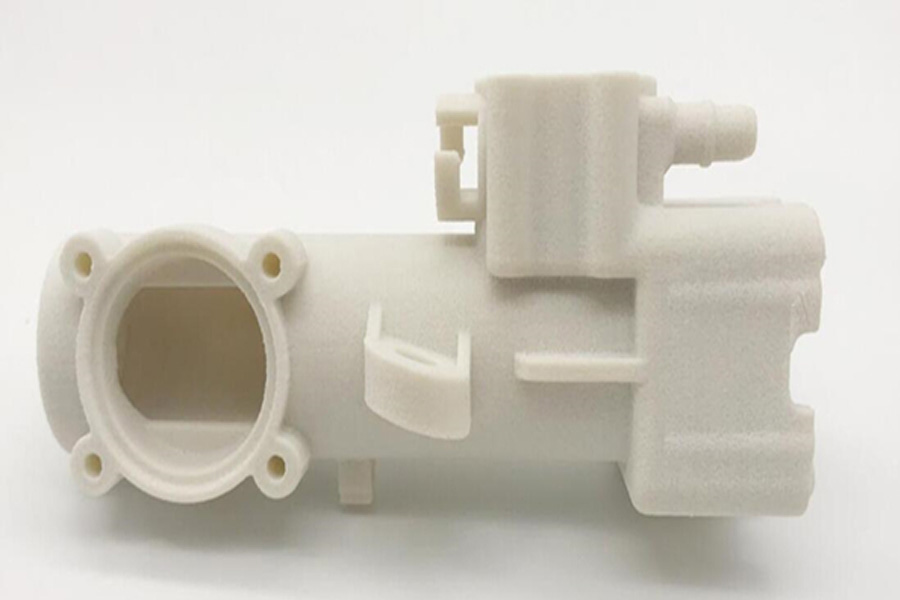

In the field of 3D printing, the addition of glass fiber improves the mechanical properties, wear resistance, thixotropy, dimensional stability and thermal deformation resistance of nylon, and effectively improves the processability of nylon. But at the same time, the addition of glass fiber also increases the surface roughness of the product, which has an adverse effect on the appearance of the product.

With the rapid development of 3D printing technology, the application of glass fiber reinforced nylon in the field of 3D printing has also been significantly increased. Glass fiber not only improves the mechanical strength of nylon to a certain extent, but also effectively improves the defects of nylon’s high thermal shrinkage rate and poor dimensional stability, making it more suitable for the needs of 3D printing materials.

Northeastern University combines ground glass fiber with cast (MC) nylon to make MC nylon/glass fiber composites. When 10% glass fiber is added, the shrinkage of the product decreases and the heat distortion temperature increases by 20. C. After the material is made into a product, the tensile strength is increased by 26%, the bending strength is increased by 13%, and the compressive strength is increased by 36%. Moreover, because nylon glass fiber has the characteristics of high strength and good toughness, its maximum molding size can reach 300 mmX 300mmX 600 mm, and the maximum molding speed can reach 10 mm/h. After receiving 3D data, arbitrarily complex models can be molded in just a few hours without bonding. Compared with traditional cutting methods, nylon glass fiber products prepared by 3D printing can greatly shorten the model making time , Reduce production costs.